Choose A Style

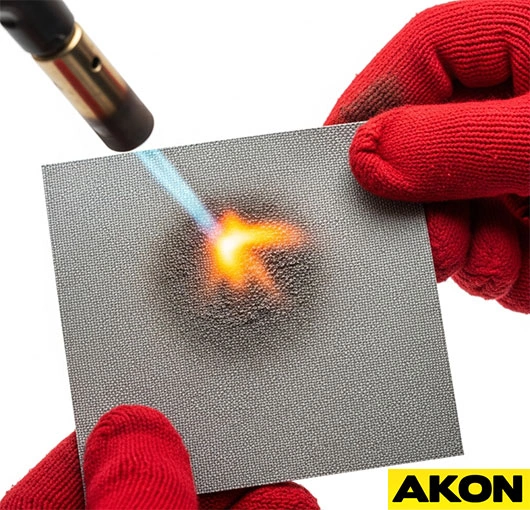

Coated Fabric Heat Strip Curtains

These heat resistant strip curtains are made for extreme heat sources up to 3,500 Degrees Fahrenheit. They have a reflective side facing the heat source to help reflect the heat source back to inside the ovens.

Silicone Heat Strip Curtains

The semi translucent heat resistant strip curtains are made for up to 446 Degrees Fahrenheit. They have excellent friction resistance and are the most economical high temperature strip curtains.

High Heat Rated

High Temperature Ratings

High temperature strip curtains are an ideal solution for areas where product or people need to pass through while containing extreme temperatures. Commonly found on ovens, and other industrial heating equipment. Also utilized at the entrance of coke ovens where conveyors feed parts into oven for curing or other processes. Heat rated strip curtains are just like clear PVC strips except they can endure excessive temperatures. You can also view our line of industrial heat divider curtains.

Advantages

- Can endure extreme temperatures

- Easy to replace when worn or damaged

- Center hole in each strip for easy bolting and attachment

- Thermal reflective side faces heat source for energy savings

- Can withstand temperature standard PVC strip curtains cannot

Frequently Asked Questions

High-temperature strip curtains are a practical solution for keeping hot work zones isolated from other parts of a facility. They have the advantage of easy access for both personnel and machinery. This material is engineered to withstand intense heat, harsh light, and continuous use, ensuring it doesn't degrade rapidly. These curtains are made to keep the heat in, which helps create a more comfortable and safe workspace. This FAQ covers how the strips hold up under tough conditions, how to put them in place, and the situations when they're most effective.

High Temperature Strip Curtains FAQ

What are high temperature strip curtains?

High temperature strip curtains are heat-resistant curtain systems made with specialty materials like silicone coated fiberglass or aluminized silica cloth. They are designed to withstand extreme heat zones in industrial ovens, foundries or heat-treating areas while allowing movement through the opening.

Where are high temperature strip curtains typically used?

They are commonly used at oven entrances/exits, heat-treating chambers, conveyor ovens, metal foundries and any industrial process where temperatures are very high and access is still required. Their purpose is to contain heat while allowing passage. :contentReference[oaicite:0]{index=0}

What materials are used in these high heat curtains?

The curtains typically use a two-layer system: a reflective layer (e.g., aluminized silica cloth) and a durable outer layer (e.g., silicone coated fiberglass). This combination retains convective heat inside and blocks radiant heat outward. :contentReference[oaicite:1]{index=1}

How hot can high temperature strip curtains handle?

Yes, they can handle very high heat. Some models withstand continuous temperatures of 1000 °F or more, and certain applications list up to 3500 °F in extreme industrial use. :contentReference[oaicite:2]{index=2}

Can these curtains reduce energy costs?

Yes, by containing high temperature zones and reducing heat loss, high temperature strip curtains help improve energy efficiency, reduce pre-heat time and maintain consistent process temperatures. :contentReference[oaicite:3]{index=3}

Do these curtains offer worker protection from radiant heat?

Yes, they reduce burn risk and exposure to radiant heat near oven openings or heat-intensive work zones. The reflective materials and insulating layers help protect personnel and adjacent areas. :contentReference[oaicite:4]{index=4}

Can I customize the strip width, length and hardware?

Yes, high temperature strip curtains are custom manufactured to fit your opening size, strip widths and lengths, material choice and mounting hardware options (grommets, tracks, rods) for your specific application. :contentReference[oaicite:5]{index=5}

Are individual strips replaceable?

Yes, individual strips can be replaced without replacing the entire curtain system. This makes maintenance simpler and more cost-effective. :contentReference[oaicite:6]{index=6}

Is installation difficult?

No, installation is straightforward. Mount the header or track, attach the strips via grommets or hooks, ensure proper overlap and curtain hang. Then align for movement through the zone. For high-heat zones you may need specialized mounting hardware rated for heat. :contentReference[oaicite:7]{index=7}

Do the curtains maintain visibility or access?

Yes, strip curtains allow passage of personnel, materials or equipment while still providing a thermal barrier. They maintain workflow without sacrificing protection.

How often should the curtains be inspected or maintained?

Regular inspection is recommended: check for wear, discoloration, damage from heat exposure, frayed edges or loose hardware. Replace strips or components as needed to maintain performance.

Are these curtains weather-proof for outdoor heat zones?

No, they are primarily designed for indoor industrial heat zones. Outdoor exposure to weather may require additional material and hardware ratings beyond standard high-temperature strip curtains.

Will the curtains help with noise or dust control?

They help contain dust, debris and radiant heat; though they are not primarily acoustic curtains, they can help with ambient dust control and some noise reduction in heavy-industrial zones.

Can the curtains be used in high humidity or spray wash areas?

Yes, but you must check the material compatibility with moisture, steam and chemical exposure. High temperature materials often tolerate heat but you’ll want to confirm suitability for humid or wash-down environments.

What maintenance helps prolong lifespan?

Keep tracks or mounting hardware free of debris, ensure proper overlap of strips, avoid contact with sharp edges, and replace damaged strips promptly. Also monitor the material for heat fatigue due to repeated cycles.

Do the curtains meet safety or process standards?

Yes, many high temperature strip curtain systems meet industrial safety and thermal barrier standards. Always confirm with your manufacturer for specific certifications and material ratings.

What is the typical lead-time for a high temperature strip curtain?

Lead time depends on size, material choice and customization. Standard units may ship quickly, while fully custom high-temperature systems could require longer manufacturing timelines.

How long will these curtains typically last?

With proper installation, use and maintenance, high temperature strip curtains can provide many years of service. Lifespan depends on how extreme the environment is, how often the strips are moved through, and how well they are maintained.

What industries commonly use high temperature strip curtains?

Industries such as metal heat-treating, glass manufacturing, steel foundries, composite curing ovens, and high-temperature manufacturing use these curtains to manage heat zones and maintain access. :contentReference[oaicite:8]{index=8}