OVERVIEW

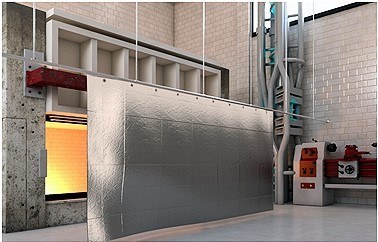

Akon provides a full range of industrial heat resistant curtains which are used to isolate heat producing ovens, equipment, and processes. These high heat curtains increase productivity and increase safety from molten splash, sparks, and the most extreme heat sources. View the different heat curtain styles below which range from heat blocking, reflecting, and insulating.

Protection From Extreme Heat

Heat Resistant Curtain Materials

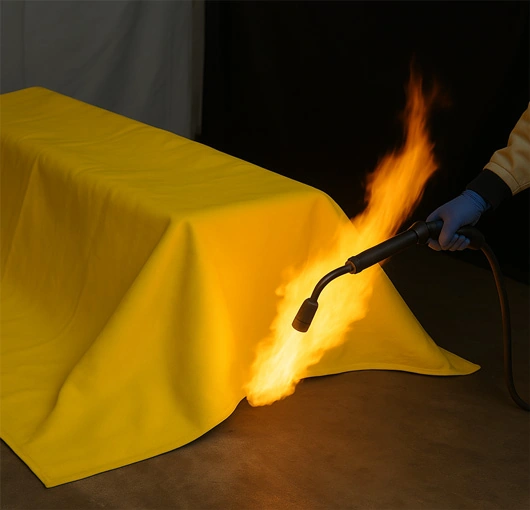

Model: CDH-1000

Curtain Color: Yellow

Material: Acrylic Coated Fiberglass – 24 oz. / .035″ thick

Temperature Rating: 1000º F

Ideal For: Sparks, Spatter and is Abrasion Resistant

Insulated: No

Reflective: No

Grommets: Every 12″ – Located at the top of the curtain

Note: Material is flexible and ideal for curtain track which allows the curtain to be pushed open.

Price: $

Model: CDH-2000

Curtain Color: Gray on both sides

Material: Coated fiberglass

Temperature Rating: 500º F continuous and 2000º F intermittent

Ideal For: Sparks, Spatter and is Abrasion Resistant

Insulated: No

Reflective: No

Grommets: Every 12″ – Located at the top of the curtain

Note: Material is flexible and ideal for curtain track which allows the curtain to be pushed open.

Price: $$

Model: CDH-3000

Curtain Color: Gray on one back side and reflective on the front

Material: Coated fiberglass / aluminized kevlar – .100″ thick

Temperature Rating: 500º F continuous and 2000º F intermittent

Ideal For: Sparks, Spatter and is Abrasion Resistant

Insulated: No

Reflective: Yes

Grommets: Every 12″ – Located at the top of the curtain

Note: Material is flexible and ideal for curtain track which allows the curtain to be pushed open. Reflects heat back to the source.

Price: $$$

Model: CDH-4000

Curtain Color: Gray on one back side and reflective on the front

Material: Coated fiberglass / aluminized kevlar – .250″ thick

Temperature Rating: 500º F continuous

Ideal For: Sparks, Spatter and is Abrasion Resistant

Insulated: Yes

Reflective: Yes

Grommets: Every 12″ – Located at the top of the curtain

Note: Ideal for static position applications. Reflects heat back towards the source and provides insulating value.

Price: $$$$

Model: CDH-5000

Curtain Color: Gray on both sides

Material: Coated fiberglass both sides – .250″ thick

Temperature Rating: 500º F continuous and 2000º F intermittent

Ideal For: Sparks, Spatter and is Abrasion Resistant

Insulated: Yes

Reflective: No

Grommets: Every 12″ – Located at the top of the curtain

Note: Ideal for static position applications. Insulated to maintain temperature zones.

Price: $$$

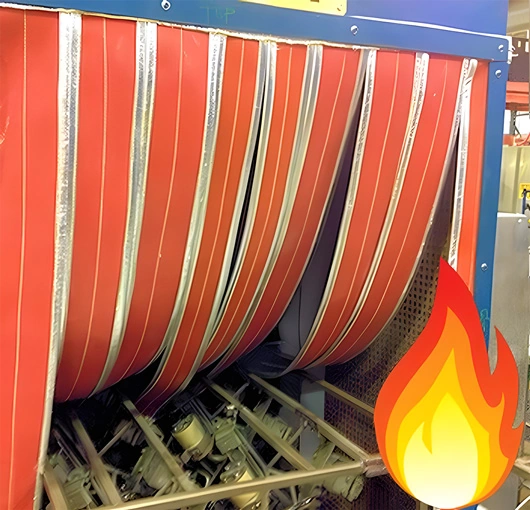

Model: CDH-6000

Curtain Color: Reflective on back and red on the front

Material: Coated fiberglass both sides – .250″ thick

Temperature Rating: 500º F continuous and 3000º F intermittent

Ideal For: Sparks, Molten Spatter and is Abrasion Resistant

Insulated: No

Reflective: Yes

Grommets: Located at the top of the curtain

Note: Ideal for applications where parts need to enter and exit areas where the high heat is present.

Price: $$$

Model: CDH-7000

Curtain Color: Gray on both sides

Material: Woven Silica

Temperature Rating: Rated for 2000º F (1100º C) continuous

Ideal For: Excellent resistance to ozone, oxidization, UV, corona, cosmic radiation, ionizing radiation

and weathering in general.

Insulated: Yes

Reflective: No

Grommets: Every 12″ – Located at the top of the curtain

Note: Ideal for static position applications. Insulated to maintain temperature zones.

Price: $$$

High Heat Endurance

Heat Resistant Strip Curtains

The material can also be fabricated into strips which allow for access into and out of areas for people or product. These industrial heat resistant strip curtains can even be used at the entrance of coke ovens where there are extreme temperatures. The heat reflecting industrial oven curtains then keep the heat inside of the oven where it is produced which in turn saves on utility costs. Heat blocking curtains can also be produced in much wider strips based on the size of the opening you are trying to cover. They are a very good solution for conveyor openings. The advantages include:

- Greatly reduce heat loss

- Can endure extreme heat that PVC strip curtains cannot

- Can be quickly replaced if damaged

- Bright colors serve as a visual barrier

Considerations for Heat Resistant Curtains

When you are choosing an industrial heat resistant curtain you need to take into consideration several factors which will help us supply the best heat reflective curtain for your application. Here are the four most important considerations:

- What is the maximum temperature the curtain will have to endure?

- How long will the curtain have to endure that temperature?

- How far away from the heat source with the curtain be located?

- Are you trying to block / reflect the heat or are to contain it?

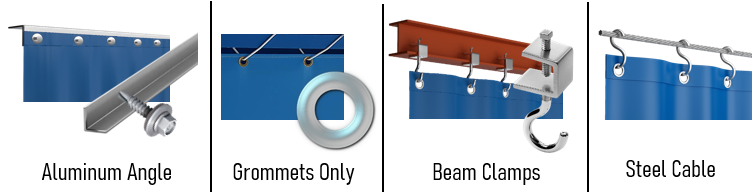

Mounting Options

There are several different options for hanging the heat resistant curtains. These include industrial curtain track which allows the curtains to roll open to allow access, or static position mounts for curtains that are fixed in place. As shown above, you can see an image showing the four most common mounts.

- The first image is a static mount that uses angle iron that is attached to the existing structure and then attached to the curtain via the grommets that are located at the top every 12 inches.

- The second image shows a track and trolley design that uses steel rollers to roll the curtain side to side.

- The third image shows a steel aircraft cable strung between two points, which allows the curtain to be supported with steel S-Hooks.

Frequently Asked Questions

Industrial heat resistant curtains protect workers and machines in facilities with welding operations and manufacturing processes that requires high heat. They make work areas safer by separating hot areas from other work areas. This keeps close workers and sensitive machines from being too hot. These curtains are used in factories and industrial shops because they can be installed faster than building walls and work best in places where the plan changes with the seasons.The FAQ below answers common questions about industrial heat resistant curtains.

Industrial Heat Resistant Curtains FAQ

What are industrial heat resistant curtains used for?

Industrial heat resistant curtains protect workers, equipment, and nearby areas from high-temperature sources. They are used around ovens, furnaces, weld zones, and other hot industrial processes.

How much heat can these curtains withstand?

Depending on the material, they handle temperatures from moderate heat up to extremely high levels. Some versions include reflective surfaces to deflect radiant heat.

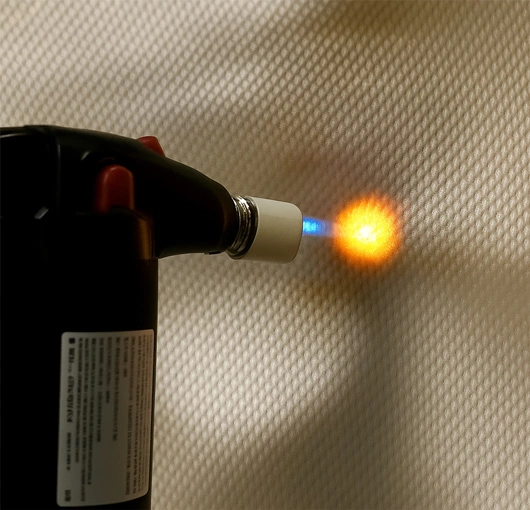

Do heat resistant curtains protect against sparks?

Yes. Many models resist sparks, splatter, and brief flame exposure, making them suitable for welding and hot work areas.

Are heat resistant curtains fire rated?

Yes. These curtains meet fire-resistant standards required for industrial safety and are built from materials designed to withstand heat and flame exposure.

Can these curtains reduce radiant heat?

Yes. Reflective coatings or metallic surfaces help bounce radiant heat away, keeping surrounding areas cooler and safer.

Are the curtains flexible and easy to move?

Yes. Even with heat-resistant layers, the panels remain flexible and slide easily along the track for quick access and repositioning.

Can I customize the size for my facility?

Yes. Curtains are built to your exact height, width, and layout requirements to match equipment and workflow needs.

Do these curtains help contain heat?

Yes. They help isolate hot zones, reducing temperature spread to nearby workspaces and improving comfort and energy efficiency.

Are heat resistant curtains safe to use near machinery?

Yes. They protect equipment from heat exposure and create safer boundaries around dangerous high-temperature operations.

Do the curtains include a track system?

Yes. Each curtain includes a heavy-duty steel track that supports smooth sliding and withstands industrial environments.

Are there different material options?

Yes. Options include coated fabrics, reflective foil surfaces, silicone-coated panels, and insulated designs depending on your heat needs.

Can these curtains be used around ovens?

Yes. They are commonly used around industrial ovens, kilns, drying tunnels, and curing areas where high heat is present.

Do heat resistant curtains help reduce energy loss?

Yes. By isolating hot zones, they help facilities maintain controlled temperatures and reduce wasted energy.

Are the curtains resistant to chemicals?

Yes. Many materials resist oils, cleaning agents, and industrial chemicals commonly found in manufacturing areas.

Can I add clear windows to heat resistant curtains?

Yes. Heat-resistant viewing panels can be added for visibility and monitoring without sacrificing safety.

Are they suitable for continuous heat exposure?

Yes. These curtains are designed to withstand ongoing heat exposure depending on the material rating and application.

How do I clean industrial heat resistant curtains?

They typically clean with mild detergent or approved industrial cleaners. The surface resists buildup and is easy to maintain.

Can heat resistant curtains be installed on existing frameworks?

Yes. They can mount to existing beams, structures, or tracks, or be ordered with new hardware for complete installation.

Do they help improve workplace safety?

Yes. They create clear boundaries that keep workers at a safe distance from hot processes, reducing burn and exposure risks.

Can heat resistant curtains be used outdoors?

They are primarily designed for indoor industrial environments but may be used outdoors temporarily if weather conditions are mild and dry.