OVERVIEW

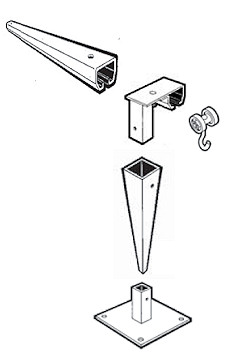

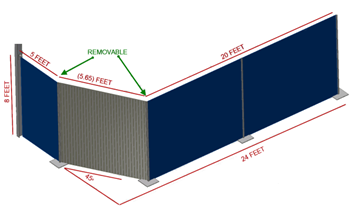

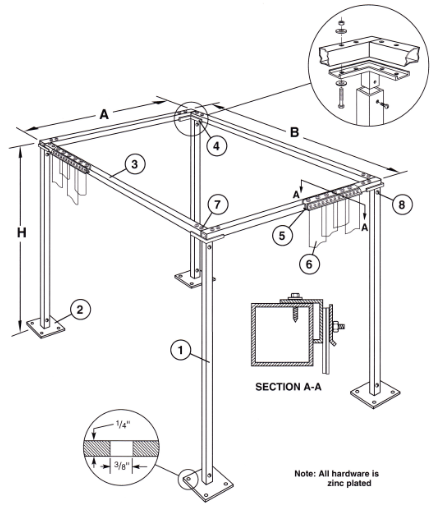

Industrial free standing curtains are supported from the floor up with base plates. Ideal when top down ceiling mounting options cannot be used or are not ideal. The 16 gauge galvanized steel hardware is designed for rugged industrial use and is quick to deploy and to take down if need be. The freestanding uprights are spaced every 8 to 10 feet allowing for complete access when the curtain is pulled back. Entry options such as strip curtains can also be added for frequent access.

Easy Install

No special tools are required. Bolt together design is quick to install and curtains quickly hang on roller hooks or zip ties.

Inexpensive

Free Standing Industrial curtains are about 1/3rd of the cost of other separation methods such as rigid walls or panels and are easy to store.

Separate Workers

Industrial curtain walls are ideal for separating workers for welding, washing, packaging and many other operations.

Control Noise

Industrial curtains help reduce noise due to the thick PVC they are made from which makes for a more comfortable work environment.

Modular Components

Enclose Work Areas

Made To Your Specifications

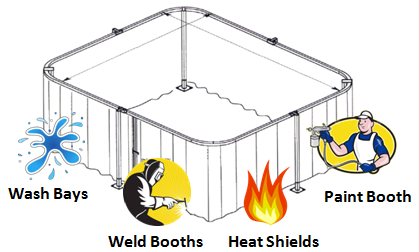

Ideal Solutions For

- Work Cells

- Dust Control Processes

- Welding Stations

- Grinding Stations

- Production Segmentation

- Wash Bay Booth

- Painting Booth

- Privacy Divider

Custom Made Per Application

The free-standing curtains are custom made to suit your application. You can have any width you need and up to 15′ in height. There are two components to the setup which includes the industrial curtains and the hardware. The curtains come in many different colors and several different materials based on your needs. Typically, they are 18oz Reinforced Vinyl for opaque colors or 20mil Vinyl for all clear curtains. You can combine static curtains with operable side-to-side curtains and strip curtains with solid curtains.

Choose Strip or Solid Walls

Strip Curtains

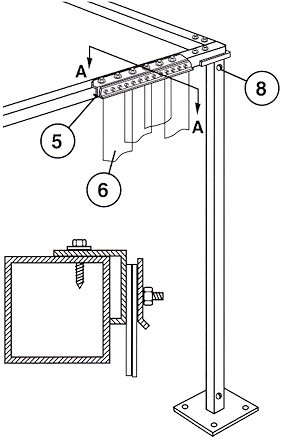

Strip Curtain Hardware

In this setup solid PVC strip curtains are bolted to the frame. The strips allow people and product to move into and out of the enclosure quickly at almost any location. With this set up, there is no need to pull a curtain back to allow access which will in turn increase efficiency for high traffic applications. The strips are clear for a line of sight and can easily be changed out if they get damaged or worn out.

Solid Curtains

Solid Curtain Hardware

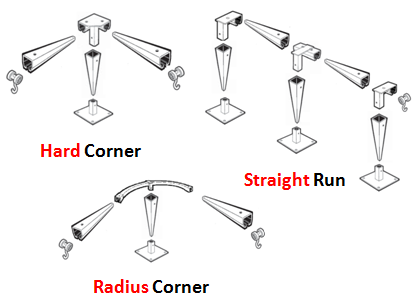

Utilizing most of the same hardware as static hardware, the rolling curtain hardware allows for side-to-side movement of the curtain walls. These Industrial Free Standing Curtains roll on curtain hooks and can have hard corners, radius corners, or no corners in case of a single sided setup. The rolling curtain track is slightly offset of the vertical uprights so that the curtain can move freely around the enclosures with no limitations.

Optional Ceilings

Ceilings Curtains

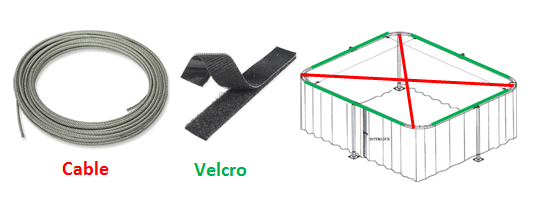

If your application requires a ceiling, Akon can provide that as well. The ceilings are a 14mil clear Vinyl that drapes over the top of the enclosure. The clear material allows light into the free-standing enclosure while containing or keeping out dust and debris. The ceilings are held up with aircraft cable (shown in red below and supplied by the customer) which spans across the top hardware and then Velcro (shown in green below) attaches to the Vinyl to the frame.

Free Standing Dust Enclosures With Ceilings

One of the most common requested features of a freestanding enclosure is a ceiling/roof. When it's not possible to run the curtain all the way to the roof deck or there are instructions above the enclosure, this is an ideal setup. It is commonly used by customers to keep dust in or out of the enclosure. Some applications include automotive sanding and prep work, industrial and commercial clean rooms, and packaging processes for warehouses.

Photo Gallery

Frequently Asked Questions

Free standing curtains support from the floor up instead of hanging from the ceiling, which brings up plenty of practical questions. Facilities want to know how stable these systems are, what height limits exist, and whether they need special tools for assembly. The choice between strip curtains and solid walls confuses people too, since each works better for different situations. This FAQ covers the real questions that come up when planning a free standing curtain system, including how the base plates anchor down, what weight the posts can handle, and which entry style fits specific work areas best.

Industrial Free Standing Curtains – Frequently Asked Questions

What are industrial free standing curtains?

Industrial free standing curtains are modular barriers that separate areas without the need for permanent walls. They are ideal for controlling dust, temperature, noise, or overspray in warehouses and factories.

What materials are used in industrial free standing curtains?

These curtains are made from heavy-duty vinyl, clear PVC, or mesh fabric. The supporting frame is typically constructed from powder-coated steel for stability and long-term durability.

Are free standing curtains fire-retardant?

Yes. Most industrial-grade vinyl materials used are flame retardant and meet NFPA fire safety standards, making them suitable for manufacturing and production areas.

Do these curtains help with dust and debris control?

Yes. They create physical barriers that keep dust, overspray, and airborne particles contained within specific zones, maintaining a cleaner and safer work environment.

Can free standing curtains help with temperature control?

Yes. Insulated or thermal vinyl curtains can help separate temperature zones, reducing heating or cooling loss in climate-controlled facilities.

How are industrial free standing curtains installed?

Installation is simple and does not require ceiling supports. The modular steel frame is assembled on the floor and the curtain panels are attached using grommets, clips, or hook-and-loop fasteners.

Can I customize the size and color of free standing curtains?

Yes. Each system is custom-built to your required dimensions, with multiple vinyl colors and clear panel options available for visibility and design preference.

Are free standing curtain walls movable or reconfigurable?

Yes. The frame and curtain panels can be relocated, resized, or rearranged easily. This makes them ideal for facilities with changing floor layouts or temporary work zones.

Do free standing curtains help reduce noise?

Yes. When paired with sound-absorbing materials, these curtains can significantly reduce noise transmission between areas or around loud machinery.

How durable are industrial free standing curtains?

They are built to withstand heavy use in industrial settings. The vinyl panels resist tearing, water, and abrasion, while the steel frames maintain stability over years of use.

Are free standing curtains suitable for outdoor use?

Standard curtains are designed for indoor environments, but outdoor-rated vinyl materials and corrosion-resistant frames are available upon request.

Can I add doors or access openings to the curtain system?

Yes. Access points such as zippered, Velcro, or strip-style doors can be built into the curtain walls for easy equipment and personnel entry.

What industries commonly use free standing curtain systems?

They are widely used in manufacturing, automotive, warehousing, aerospace, and food processing industries for flexible space division and containment.

Can I connect multiple free standing systems together?

Yes. Multiple frames can be joined with connectors or overlapping panels to create larger enclosures or multi-zone configurations.

Are replacement curtain panels available?

Yes. Individual panels can be replaced or upgraded without changing the existing frame, allowing for easy maintenance or design updates.

How tall can free standing curtain walls be built?

Heights typically range from 6 feet to 20 feet, depending on the required containment and frame design. Taller structures include reinforced bases for extra stability.

Can clear panels be added for visibility?

Yes. Clear PVC vision panels can be integrated into solid vinyl curtains, offering visibility while maintaining separation between work areas.

How do I clean and maintain the curtains?

Simply wipe the curtain surfaces with mild soap and water. Avoid harsh solvents or abrasives to preserve the vinyl’s clarity and longevity.

Where can I order custom free standing curtain systems?

You can order directly through AKON by submitting your measurements and layout. The team will assist with design, quote, and production to meet your facility’s needs.

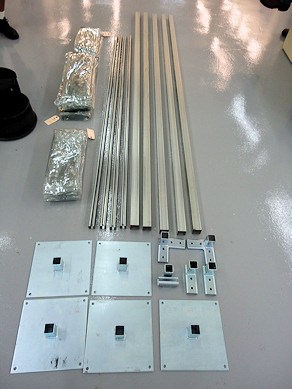

Construction

- Galvanized steel - Hot-dip galvanizing (HDG)

- Lifetime warranty

Uprights

- 2" x 2" OD square tubes

- Tube size selected based on curtain heights

- Max height is 12'

- Maximum distance between uprights is 10′ for solid

curtains and 8′ for strip curtains. - Layout drawing provided with each order for your

approval

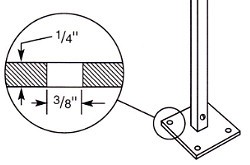

Base Plates

- 12" x 12"

- 3/8" lag holes located in each corner

Assembly

- Your order will arrive as a bolt together kit

- Simply assemble the hardware and then hang the curtains

Strip Mount Style

- Strips attach to horizontal cross members

- Strips bolt on for secure locking

- Strips can unbolt to be replaced quickly

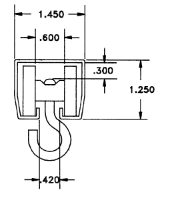

Rolling Curtain Mount Style

- Curtains attach to nylon roller hooks

- Curtains roll side-to-side for complete access