OVERVIEW

Industrial canvas welding curtains are made for heavy duty welding applications, unlike vinyl welding curtains that are designed only for light-duty to medium duty welding. The canvas weld curtains are constructed of flame retardant fiberglass and has a temperature range of 350°F to 3000°F, depending on the type of material. These curtains are an ideal solution for keeping your workers safe and also for blocking heat sources. Made for close proximity where heavy welding sparks will hit the curtains.

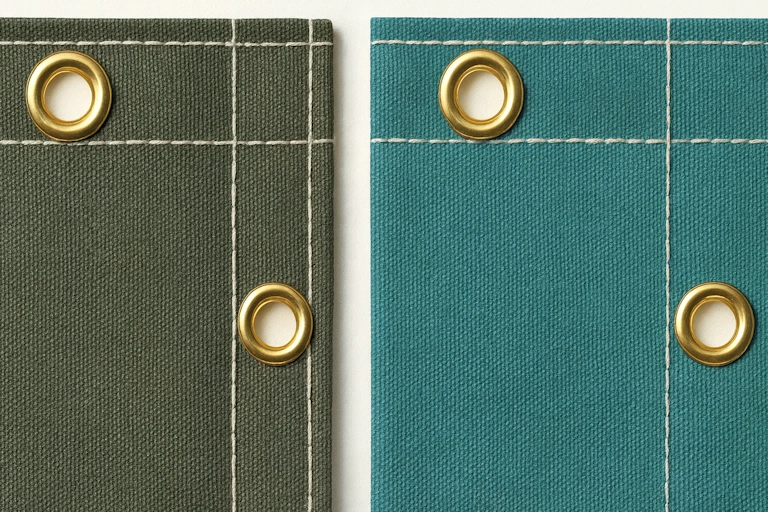

12oz – Canvas Duck – Olive Green & Blue

- Industrial Grade Canvas

- Blocks most UV radiation

- Weight: 12 oz./sq. yd

- Thickness: 0.025″

- Temp Rating: 350°F

- Color: Olive green

- Meets CPAI-84 section 6, CFM

- Certified Flame Retardant

- Grommeted on top side 12″ apart

- Flame, water, and mildew resistant

- Also available in multiple standard sizes, custom, and rolls

- Water repellent and mildew resistant (Pyrosnuff treatment)

- Great resistance to adverse environments

Canvas Hotwork Curtains

Close Range Welding

The best option for close range welding operations is canvas welding curtains, which offer vital protection for both welders and onlookers. These curtains are a preferred pick for many welding operations since they were made with durability and safety in mind. Canvas welding curtains are made of flame-resistant materials and protect workers from dangerous UV radiation, sparks, and splatter, lowering the possibility of accidents and injuries. Additionally, they are portable and lightweight, making it simple to carry, set up, and reconfigure them in any welding setting.

Canvas Welding Curtains Vs. Vinyl

Canvas welding curtains are a better option than vinyl substitutes because of their improved heat resistance and longevity. Canvas curtains, which are made of flame-resistant materials, can withstand the high temperatures produced during welding, but vinyl curtains are more likely to melt with close range welding. Canvas curtains ensure a safer working environment by offering exceptional defense against damaging UV rays, sparks, and splatter. In conclusion, canvas welding curtains beat vinyl alternatives in terms of safety, durability, and overall performance, providing a strong and dependable solution for welding applications.

Canvas Welding Enclosures

There are numerous advantages of using canvas welding curtains to enclose welding operations that include increased productivity, efficiency, and safety in a variety of industrial situations. These unique canvas curtains provide several significant benefits while acting as a crucial barrier between welding processes and the environment. In welding operations, safety is of the utmost importance, and welding canvas curtains assist to shield both welders and onlookers from potential dangers. These curtains dramatically lower the risk of accidents, injuries, and eye damage by providing protection from dangerous UV radiation, sparks, and splatter. Another significant advantage of canvas welding enclosure curtains is noise reduction, since they feature sound-dampening qualities that assist reduce excessive noise levels and promote a more favorable work atmosphere. Last but not least, welding curtains' adaptability and simplicity of installation make it possible for companies to quickly modify workstations to suit shifting needs. Their adaptable designs offer effective space management, assuring best use of the resources available.

Easy Install

Welding curtain walls come with grommets at the top, making hanging the welding curtains quick and easy with or without the curtain track.

Welding Certified

AKON welding vinyl walls are certified for welding operations with fire retardant ratings and UV blocking properties.

Protects Welders

Hanging welding curtain walls are ideal for protecting welders from arc flash and sparks that present a safety hazard.

Control Noise

The tinted PVC welding curtains protect your eyes from welding UV rays and also reduce noise due to the thick PVC they are made from.

Complete Containment Solution

Portable Canvas Welding Screens

If you need to move your canvas welding curtains around, then you can use canvas welding screens. The shields are made from the same industrial canvas welding curtain material as the side-to-side curtains.

Frequently Asked Questions

Canvas welding curtains handle extreme temperatures from 350 to 3000 degrees depending on the material grade, which keeps them from melting or catching fire when sparks land directly on the fabric. Heavy fabrication shops use these for close range welding where sparks hit the curtains constantly throughout the day. The fiberglass construction blocks UV radiation better than vinyl while also dampening noise from grinding and welding operations. Canvas costs more upfront but lasts way longer in harsh welding environments. This FAQ covers what temperature rating actually means for different welding processes, whether canvas really outperforms vinyl enough to justify the price difference, and how these curtains hold up to daily spark bombardment over time.

Canvas Welding Curtains – Frequently Asked Questions

What are canvas welding curtains used for?

Canvas welding curtains are used to create heavy-duty barrier zones around welding operations, protecting adjacent areas from sparks, slag, UV radiation and high heat environments.

What materials are canvas welding curtains made from?

They are typically constructed from flame-retardant coated canvas or fiberglass canvas material rated for high temperatures and designed for close-proximity welding conditions.

Are canvas welding curtains flame-resistant?

Yes, canvas welding curtains use flame-retardant fabrics certified for industrial welding zones, helping meet fire-safety and OSHA requirements in high-heat applications.

Do canvas welding curtains block welding arc flash and UV?

Yes, when properly tinted and constructed these curtains help filter arc flash, UV light and spatter, increasing safety for workers and equipment nearby.

Can canvas welding curtains be customized to fit my facility?

Yes, they can be custom sized in width, height, thickness, color and configuration to fit your manufacturing, fabrication or welding cell layout.

How are canvas welding curtains installed?

Installation typically involves ceiling or wall-mounted tracks, grommets, cable systems or rod support. Secure mounting is vital for safe barrier performance in welding zones.

Do canvas welding curtains include clear view panels?

Yes, clear vinyl or polycarbonate windows can be integrated for supervision and natural light while maintaining welding zone containment.

Can canvas welding curtains be used outdoors?

Yes, outdoor-rated versions are available with UV- and weather-resistant finishes and corrosion-resistant hardware for semi-open fabrication areas.

Do canvas welding curtains reduce noise?

Yes, their dense fabrics provide some acoustic dampening, helping reduce ambient noise from welding operations and improving the work environment.

Are replacement panels available for canvas welding curtains?

Yes, individual curtain panels, grommeted sections and hardware components can be replaced without full system teardown, reducing maintenance costs.

Do canvas welding curtains support high-temperature applications?

Yes, heavy-duty canvas curtains are designed for close-proximity welding with slag, spatter and heat loads, sometimes rated up to thousands of degrees °F.

Can canvas welding curtains improve workflow and safety zones?

Yes, they create clear zone separation, restrict access, and allow multiple welding cells operating in proximity without cross-interference or hazard exposure.

Are the curtain materials easy to maintain?

Yes, cleaning and maintenance are minimal. The heavy-duty canvas material can be wiped down, inspected for damage and repaired or replaced as needed for longevity.

Do canvas welding curtains comply with welding safety standards?

Yes, they help meet standards such as OSHA and ANSI for welding zones, arc flash protection and work-cell separation when properly specified and installed.

What sizes are typical for canvas welding curtains?

Typical widths range from 8 ft to 20 ft or more and heights from 6 ft to 16 ft, with fully custom sizes available for unusual facility layouts.

Can canvas welding curtains protect equipment adjacent to welding cells?

Yes, by shielding nearby equipment and workstations from heat, slag and spatter you reduce damage, maintenance and downtime across the facility.

How long do canvas welding curtains last?

With proper installation and maintenance, these curtains typically last 5-10 years or more in industrial welding environments depending on exposure and usage.

Do canvas welding curtains support mobile or modular layouts?

Yes, they can be configured in modular section systems, foldable or mobile track systems allowing flexible zone reconfiguration as production needs change.

Are replacement accessories available?

Yes, accessories such as mounting grommets, track wheels, cables, sliders and connection hardware are available to maintain your curtain system efficiently.

How do canvas welding curtains compare to vinyl welding curtains?

Canvas welding curtains offer superior heat and slug resistance compared to vinyl, making them ideal for heavy welding applications whereas vinyl suits lighter duty zones.

Photo Gallery

Rolling Hardware

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.