Choose From Solid or Strips

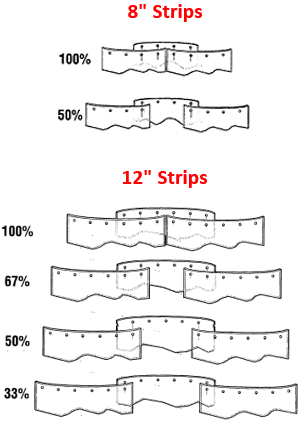

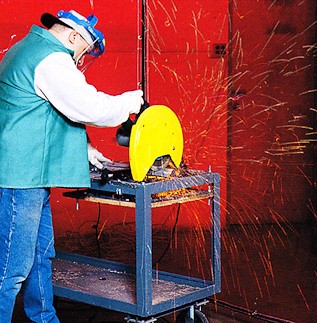

Free Standing Welding Strips

Free-Standing welding strip curtains allow entry

at all locations of the enclosure. This allows

people and product rapid access.

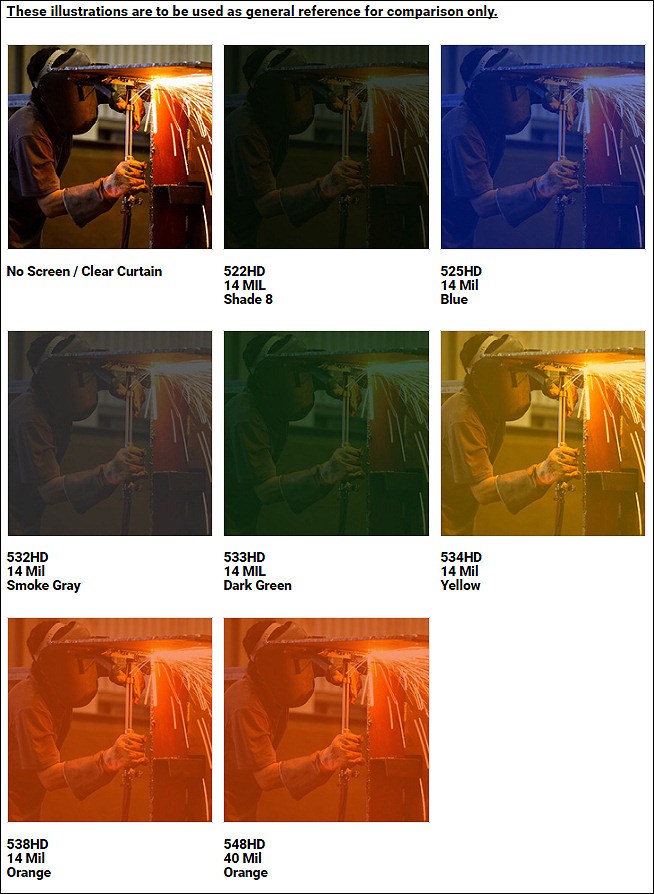

Free Standing Welding Curtains

Less expensive than the full strip curtains

the solid soft wall curtains are made from

14mil Vinyl and roll side-to-side.

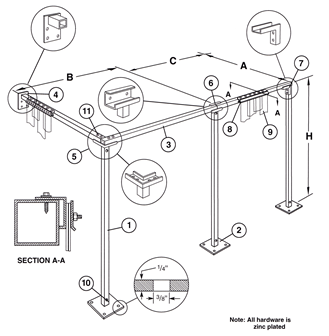

Rugged Industrial Hardware

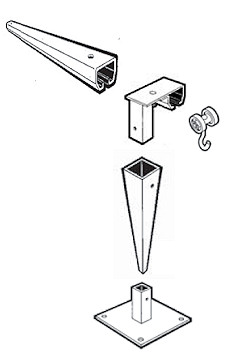

Strip Hardware

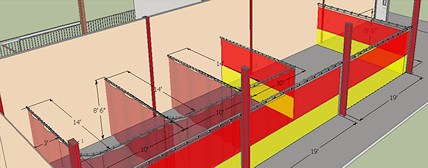

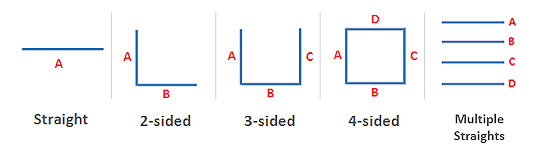

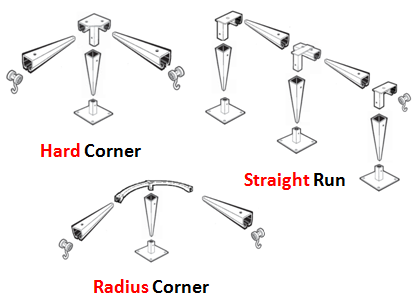

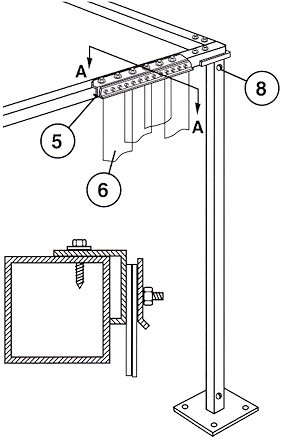

Using the same studded hardware as a traditional strip curtains, the welding strips attach to the galvanized steel frame and securely bolt on. This prevents the strips from coming detached when material moves through. You can form a 4-sided freestanding welding cell or single-sided freestanding welding walls. We can accommodate almost any design your welding area requires.

Curtain Hardware

The soft wall welding curtains can roll side-to-side using the roller hooks that roll inside of the curtain track. This allows easy and efficient entry from one side to the other. Just like the welding strip curtains, any configuration is possible from 4-sided welding enclosures to single-sided. The welding curtain track is a bolt-together design that allows for quick deployment.

Frequently Asked Questions

Free standing welding curtains support from the floor up instead of hanging from ceilings, which solves problems in facilities where overhead mounting just does not work. The galvanized steel posts and base plates create welding booths anywhere on the shop floor without drilling into roofs or beams. Shops choose between strip curtains that allow constant walk-through access or solid curtains that slide on tracks for wider openings. The bolt-together design means welding cells can move or reconfigure as production layouts change. This FAQ covers how stable these systems stay without ceiling support, whether base plates need bolting down or just sitting on the floor works, and if the maximum height really handles typical welding booth needs.

Free Standing Welding Curtains – Frequently Asked Questions

What are free standing welding curtains used for?

Free standing welding curtains are used to create independent welding enclosures without the need for ceiling mounting, providing flexible separation of welding zones for safety and productivity.

What materials do free standing welding curtains use?

They typically feature flame-retardant vinyl, reinforced PVC or canvas hung from a self-standing frame, designed to resist welding spatter, UV arc flash and industrial wear.

Are free standing welding curtains flame-resistant?

Yes, they are built with fire-retardant materials and hardware that comply with welding and hot-work safety standards in industrial fabrication zones.

Do free standing welding curtains block UV and arc flash?

Yes, when tinted correctly, these curtains help filter out harmful UV rays and bright welding arcs to protect adjacent workers and equipment.

Can I customize free standing welding curtains?

Yes, you can specify width, height, frame design, material type and color options to match your facility layout and workflow needs.

How is a free standing welding curtain installed?

Installation involves assembling upright frame posts and cross-members on the floor and then attaching the curtain material, offering flexibility without ceiling attachment.

Do free standing welding curtains include vision panels?

Yes, optional clear vinyl or polycarbonate window sections can be integrated to maintain visibility while preserving protective separation.

Can free standing welding curtains be moved or reconfigured?

Yes, many units are modular with bolt-together frames so you can reconfigure layouts or relocate zones as production needs change.

Are free standing welding curtains suitable for outdoor or semi-outdoor use?

Yes, when specified with UV- and weather-resistant materials and corrosion-resistant hardware, they can be used in covered outdoor welding zones.

Do free standing welding curtains help reduce noise?

They can help isolate noisy welding operations from adjacent work areas, contributing to reduced sound propagation and improved facility environment.

Are replacement panels or frames available?

Yes, individual curtain panels, frame components and hardware can be replaced independently to help reduce downtime and maintenance cost.

How long do free standing welding curtains typically last?

With proper maintenance and usage they normally last 5-10 years or more, depending on exposure to heat, traffic and maintenance practices.

Do free standing welding curtains aid in safety compliance?

Yes, by defining welding zones and providing physical barriers they support compliance with safety standards such as OSHA and ANSI for welding workspaces.

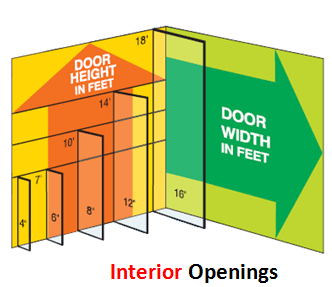

What sizes are available for free standing welding curtains?

Available sizes vary widely; typical widths are 8-20 ft+ and heights 6-16 ft+, with custom sizing available to fit specific fabrication cell layouts.

Can free standing welding curtains protect adjacent equipment and personnel?

Yes, they shield nearby machines, tooling and staff from welding sparks, spatter, heat and harmful arc flash exposure, improving safety and reducing downtime.

Are free standing welding curtains easy to maintain?

Yes, maintenance is minimal: wipe down surfaces regularly, inspect frame hardware and replace damaged curtain sections when necessary to maintain performance.

Do free standing welding curtains support modular or combined layouts?

Yes, you can combine multiple units to create larger enclosures, linking frames or curtains to build extensive welding zones using modular design.

Can free standing welding curtains integrate with ventilation or fume extraction?

Yes, they can be used in tandem with fume extraction or local ventilation systems to help manage welding gases and direct airflow appropriately.

Are free standing welding curtains more cost-effective than permanent walls?

Yes, they typically cost less than permanent wall construction, offer quicker setup, easier relocation and lower lifetime maintenance, making them a flexible alternative.

What are the advantages of free standing welding curtains compared to mounted systems?

They offer floor installation without ceiling attachment, modular flexibility, ease of relocation, minimal facility modifications and rapid deployment versus ceiling-mounted systems.

Photo Gallery

Construction

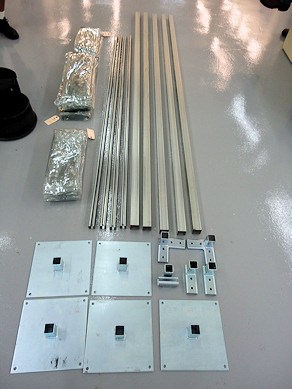

- Galvanized steel - Hot-dip galvanizing (HDG)

- Lifetime warranty

Uprights

- 2" or 2" OD tubes

- Tube size selected based on curtain heights

- Max height is 12'

- Maximum distance between uprights is 10′ for Vinyl

curtains and 8′ for strip curtains. - Layout drawing provided with each order for your

approval

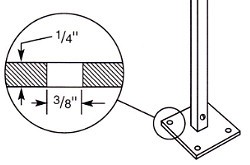

Base Plates

- 12" x 12"

- 3/8" lag holes located in each corner

Assembly

- Your order will arrive as a bolt together kit

- Simply assemble hardware and then hang the curtains

Strip Mount Style

- Strips attach to horizontal cross members

- Strips bolt on for secure locking

- Strips can unbolt to be replaced quickly

Rolling Curtain Mount Style

- Curtains attach to nylon roller hooks

- Curtains roll side-to-side for complete access

Build Online Now

Free-Standing Welding Strips