OVERVIEW

SB11000, the Safety Roll Up Guard offers your employees with the critical protection against weld flashes, bustling debris, with added advantage of preventing accidents by blocking access to dangerous machinery parts. The innovative safety shield can be rolled up or down, and can also be rotated 360 degrees to facilitate complete access inside any work cell, a feature all other safety curtains fail to offer.

The curtain can be locked up in any upright position with a gentle tug on the provided nylon strap, courtesy of the robust ratchet roller. The integral design means the curtain is attached to the roller with the hook along with a loop fastener assembly making it very convenient to replace if damaged.

Rolls Up and Swivels

Roll Down Welding Guard

Depending upon the space available at the facility, the most suitable welding guard mount can be chosen from the options of free-standing mount base, hanging via chains or hooked onto a wall or beam. The various supported mounting styles make it possible to create uniquely designed small or large work areas for welding. The roll down welding guard protects the by standers and fellow workers from harmful elements such as welding sparks and flying debris.

When not in use, the safety guards can be packed in any position either in full up or in full down position. Working height can be adjusted with the help of the ratchet to lock the shade at the desired position.

Common Uses

- Roll Up Welding Guard

- Roll Up Robotic Cell Guard

- Pull Down Work Cell Shield

- Industrial Welding Shade

Roll Up Safety Guard Benefits

- Increases accessibility of the workplace

- Ends any need to manually move safety guards

- Maximises efficiency in facility space utilization

- The shields can be deployed without creating any obstruction for workers

- Swivels 360 degrees for quick overhead access

- The industrial vinyl is easily replaceable if any impairment occurs

Specifications

- Height: Up to 10′

- Length: Up to 15′

- Horizontal movement: 360 degrees using the hand-held bar

- Vertical movement: Possible using the hand-held bar

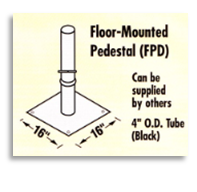

- Mount plate: 16″ x 16″ x 3/8″

- Post: 4″ diameter tubing of steel

- Bumper stop: Yes – avoids overs-stretching of the guard

- Shields per post: 2 shields can be hooked to one post for extra protection on corners

- Roller: Heavy duty with 3″ diameter equipped with locking ratchet assembly

- Protection from: Sparks, heat, ultraviolet light, and flying debris

- Service range: -40° to 180° F continuous

- Solid fabric: Vinyl-coated 16 oz., resists oils, fire, most acids

water, alkalis, welding sparks, mildew, and grinding sparks, CFM approved - Transparent fabric: 3° to 165° F continuous, CFM approved

- Fabric replacement: Yes – can be easily and quickly replaced if damaged

Mounting Options

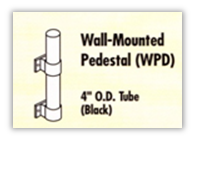

Wall-Mounting

The Roll-Up Safety Guard can be mounted to the face of a wall or beam. It can then swivel or be fixed in position.

Floor-Mounting

A floor pedestal which anchors into the cement floor can be used to mount the industrial roll up welding guard. It can also swivel or be fixed in position like the wall mount.

Chain-Mounting

At no additional cost the standard chain supported mount is included. Chains drop down from above to hold up the roll up guard.

Frequently Asked Questions

Roll up safety guards protect busy work areas by dropping down when needed and rolling back up to clear floor space. The barrier keeps sparks, dust, and light debris away from nearby workers and equipment without taking up room like permanent walls do. Facilities use these in tight spots where fixed barriers block movement or equipment access. The material handles daily use and cleans up easily after exposure to shop dirt and grime. Shops wonder whether the rolling mechanism jams after months of constant deployment. This FAQ covers how the roll system actually operates, what kind of lifespan to expect from regular use, which mounting options work for different ceiling types, and whether these guards meet safety codes for machine guarding applications.

Roll-Up Safety Guard FAQ

What is a roll-up safety guard?

A roll-up safety guard is a retractable welding curtain system that rolls vertically (or optionally horizontally) to provide a protective barrier around welding cells. It helps shield workers from UV flash, sparks, flying debris and maintains access when not in use.

How does the roll-up safety guard improve shop safety?

It improves safety by giving you flexible protection: you deploy the curtain when welding and roll it up when not needed. This reduces exposure to UV light, spatter and sparks, while allowing access and visibility when the cell is idle.

Is the roll-up safety guard fire-resistant?

Yes, the curtain material is fire-resistant vinyl or PVC designed for welding environments. It self-extinguishes and meets flame-retardant industrial standards making it safe for use near welding operations.

Can the roll-up safety guard accommodate overhead crane movement?

Yes, because the curtain rolls out of the way when not in use, it allows overhead cranes or material handling systems to operate freely above the cell. This makes it ideal for dynamic production environments.

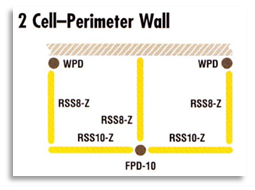

Can I use this with multiple welding stations or cells?

Yes, the system is designed to scale: one pedestal can hold multiple curtain shades, or multiple units can be linked to form larger protective zones. This makes it suitable for work cells that change frequently.

How easy is it to install the roll-up safety guard?

Installation is straightforward: mount the pedestal base and roll-tube, attach the shade, and hook to a j-hook or opposing post. Once mounted, it retracts or rolls out smoothly and requires minimal maintenance.

Is the roll-up safety guard mobile?

Yes, many roll-up safety guard models come with a mobile base or casters so you can reposition the system as your shop layout changes. This mobility adds flexibility in dynamic welding environments.

Can I choose different curtain materials and colours?

Yes, you can select from different vinyl or PVC materials, different thicknesses, and a variety of colours (such as orange, blue, dark green) to match visibility needs and welding amperage levels.

What size options are available?

The roll-up guard is available in various widths and heights to suit your cell. Custom sizes are also available for atypical workcells or robotic welding where larger coverage is required.

Does it block welding UV light?

Yes, the correct curtain shade will block welding UV and infrared light, protecting passers-by and adjacent work areas. Always check material specs to ensure it matches your amperage and process.

Are replacement curtain shades available?

Yes, you can order replacement shades without replacing the full system. This keeps maintenance costs lower and allows for quick replacement if the curtain gets damaged or worn.

Is the roll-up safety guard compatible with existing mounts or walls?

Often yes — it can be mounted to existing wall structure or steel columns via j-hook attachments or bracket kits. However, using the recommended pedestal or post ensures optimal performance and retraction.

Does the unit comply with industrial safety regulations?

Yes, when installed correctly, the roll-up safety guard helps you comply with industrial safety standards covering welding flash, arc light, and flying debris. Using appropriate materials and following manufacturer guidelines is key.

How do I roll the curtain away when not in use?

The roll-tube mechanism allows the shade to retract automatically (or manually) into a compact form. This keeps the work area clear for material movement or overhead crane access when welding is not active.

Can the roll-up guard reduce noise or sparks?

Yes, it provides a physical barrier that helps contain sparks, spatter and some noise. While it is not a full acoustic enclosure, it improves the safety and comfort of adjacent work zones.

Is the roll-up safety guard suitable for mobile or temporary setups?

Yes, many models are designed for portability, making them ideal for temporary welding cells, mobile fabrication shops, or changing production layouts. The roll-up mechanism makes setup and teardown faster.

Does it require maintenance?

Yes, you should keep the roll-tube mechanism clean and inspect the shade for wear or tears. Lubricate bearings if applicable and ensure the j-hook attachments remain secure. Proper maintenance extends service life.

Is the roll-up guard weatherproof for outdoor welding?

No, typically it’s designed for indoor industrial use around welding cells. If you plan outdoor usage you should verify weather-rated materials, rust-proof hardware, and potential UV degradation.

What is the lead time for delivery?

Lead times vary depending on size, material and custom options. Standard models may ship quickly, while custom-sized units might require manufacturing lead time. Check with your supplier for current timelines.

How long will the roll-up safety guard last?

With proper installation and maintenance, the system can last many years. Key factors include usage frequency, welding environment severity, and material selection. Replacing worn shades helps maintain longevity.