MODEL - SB-5000

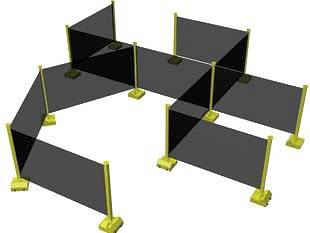

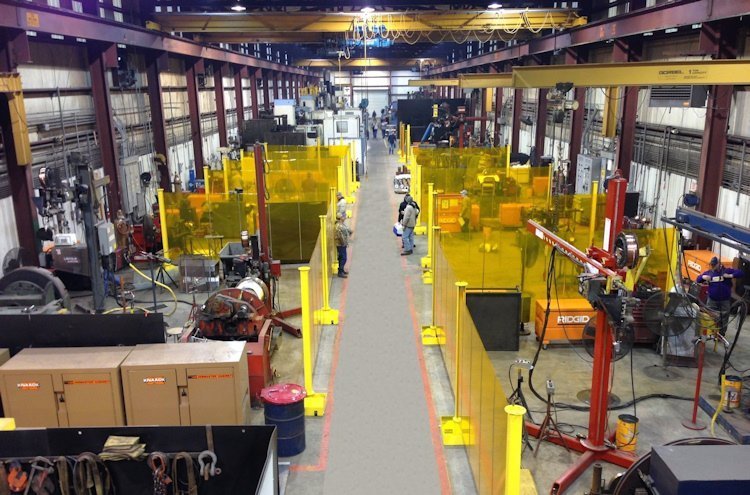

The welding roll up curtains are lightweight, durable, and are portable so they can be moved to anywhere some welding is to be done. With an integrated design, transportation and installation is very easy and quick. As the mobile welding screens are designed to be entirely free-standing. Almost any cell configurations can be constructed from them. The wheels installed on the pedestal base make it very to transport without much effort.

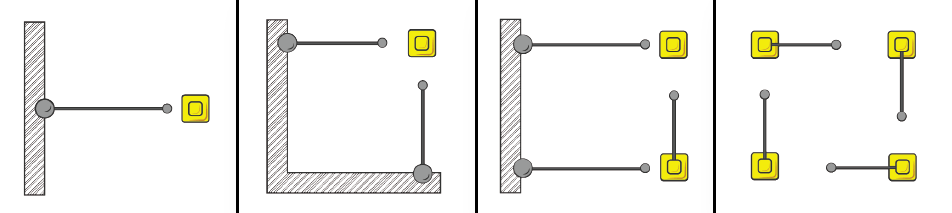

Possible Layouts

Collapses To Allow For Full Access

Shades Roll Out When Needed

Once it is time to begin welding operations the operator hand walks the shades to an adjacent post and then he can begin welding.

Shades Roll Up When Not Needed

The tinted welding screens roll up when not needed to provide full access into and out of the welding cells.

Roll Away When Not Needed

Unlike anchored welding screen welding cells. The SB-5000 can be tilted backwards and rolled away from production for 100% access!

Retractable Welding Cells

Change As Your Needs Change

Portable For Speed and Flexibility

Roll Up Safety Guard Benefits

- Heavy duty steel posts securely hold the roll up welding curtains.

- Ideal for all welding application including TIG, stick welding, and MIG.

- Helps reduce UV exposure for by passers

- The vertical pedestal is bright yellow for high visibility and safety.

- Shades can connect to existing walls or beams with included hooks.

Roll Up Welding Curtain Benefits

- Reduced UV radiation caused by welding.

- Increased flexibility for changing welding cell needs.

- Takes up less space for a more efficient work place.

- Reduces congestion where materials need to flow.

- Connect up to 4 shades to a single post for multiple cells.

- Allows for access of overhead cranes that move material in.

Watch The Curtains in Action

Frequently Asked Questions

Roll up welding curtains mount on wheeled posts that move around the shop floor to create temporary welding cells wherever needed. The shades pull out between posts and lock in place during welding, then roll back up to allow full access when work finishes. Each post connects up to four shades, which lets shops build custom cell configurations that change as production needs shift. The entire setup tilts back and rolls away completely unlike fixed welding booths. This FAQ covers how stable these stay during welding, whether the spring mechanism holds up over time, and if the posts tip over easily when moving them around tight spaces.

Roll Up Welding Curtains – Frequently Asked Questions

What are roll up welding curtains used for?

Roll up welding curtains are used to create retractable safety barriers around welding cells, enabling quick access while protecting adjacent work areas from sparks, heat, and UV arc flash.

What materials are roll up welding curtains made from?

They are typically constructed from flame-retardant vinyl or reinforced PVC mounted on roller hardware, often tinted to filter arc flash and designed for durability in welding environments.

Are roll up welding curtains flame-resistant?

Yes, the materials used are flame-retardant and comply with industrial safety standards to reduce fire risk in welding applications and fabrication shops.

Do roll up welding curtains block UV and arc flash?

Yes, when equipped with tinted vinyl or special filter layers, they help reduce exposure to hazardous UV radiation and bright welding arcs in nearby workspaces.

Can roll up welding curtains be customized?

Yes, they can be customized in width, height, roller configuration, material thickness, color tint, and mounting system to meet your facility’s workflow and spatial needs.

How are roll up welding curtains installed?

Installation typically includes overhead roller tubes or side-mount tracks, ceiling or wall anchors, and guided rails to ensure smooth operation and proper barrier containment.

Do roll up welding curtains include clear vision panels?

Yes, optional clear vinyl or polycarbonate windows can be integrated to allow visibility and supervision while maintaining protective welding zone separation.

Can roll up welding curtains be used outdoors?

Yes, outdoor-rated versions are available with UV-resistant materials and corrosion-resistant hardware suitable for covered or semi-open fabrication areas.

Do roll up welding curtains help reduce noise?

Yes, by creating defined barriers they assist in reducing welding cell noise and improving the acoustic environment in adjacent zones of the facility.

Are replacement roller components or panels available?

Yes, panels, roller tubes, track hardware and mounting elements can be replaced without removing the entire system, making maintenance and repair more cost-effective.

Can roll up welding curtains support mobile or modular layouts?

Yes, modular roller systems, fold-away configurations, or mobile mounts allow flexible reconfiguration of welding zones as production or layout needs change.

Are roll up welding curtains compatible with fume extraction systems?

Yes, they integrate well with welding exhaust and ventilation by providing zoned containment to direct airflow and help manage welding fumes and contaminants.

How long do roll up welding curtains last?

With proper use and maintenance, roll up welding curtains typically last 5-10 years or more, depending on exposure to sparks, heat, and frequency of use.

Do roll up welding curtains help with safety compliance?

Yes, they support compliance with safety standards such as OSHA and ANSI by defining welding zones and protecting adjacent areas from arc flash and hot spatter.

How much maintenance is required for roll up welding curtains?

Maintenance is minimal: check roller mechanisms, clean tracks, inspect curtain material for wear, and perform occasional panel replacement to extend life.

What sizes are typical for roll up welding curtains?

Typical widths range from 10 ft to 30 ft or more and heights from 6 ft to 20 ft, with custom sizing available to match your facility’s equipment and layout.

Do roll up welding curtains protect adjacent equipment and workspaces?

Yes, they shield nearby machines, tooling, and workers from welding spatter, heat and UV exposure, reducing damage and maintenance downtime.

Can roll up welding curtains be motorized or manual?

Yes, some systems include manual crank or chain mechanisms, while others offer motorization for large spans or automated production cells.

Are roll up welding curtains more expensive than standard curtains?

Generally yes, due to the roller hardware, custom sizing, and automation options, but the added flexibility and workspace savings offset the cost.

What are the advantages of roll up welding curtains over fixed barriers?

They provide fast access, improved workflow, retractability, cleaner design, better zoning, and less permanent footprint compared to fixed metal panels or rigid barriers.

Common Uses

- Portable welding screens

- Removable welding guards

- Mobile welding shades

- Portable welding curtains

- Modular welding work cells

Pedestal

- Dimensions: 20.40" x 20.40" x 96" tall

- Weight w/o ballast: 105lbs

- Est. weight w/ ballast: 205lbs

- Weight for base pans not included

- Pedestals without shades can also be purchased

- Springs are rated for up to 250,000 cycles

Shade Attachment

- Shades attach with supplied J-Hooks

- Can attach to another post or existing walls, beams..ec

- 4 shades can connect to a single post

Shade Size

- 5' 6" high x 20' wide

- Custom shade sizes available (No taller than 6' or wider than 20') +$280

Shade Colors

- Semi Transparent Orange

- Semi Transparent Blue

- Semi Transparent Dark Green +$120

- Semi Transparent Yellow +$120

- Semi Transparent Gray +$120

- Clear - +$120 (Will No Block UV Light)

- Opaque Yellow +$120

- Opaque Blue +$120

- Opaque Green +$120

Shade Material

- Semi Transparent Shades: 14mil PVC Welding Screen

- Opaque Shades: 18oz PVC Welding Screen

- Fire retardant | CFM Rated

WARNING: Tinted transparent vinyl screens provide protection for casual passerby only and are not intended as a substitute for normal eye protection for close or long-term viewing. The user must wear protective eye-wear suitable for the application. Clear transparent vinyl does not reduce harmful UV light from welding operations.