OVERVIEW

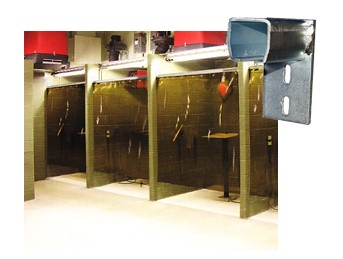

Vinyl welding booth curtains are opaque solid curtains or strip curtains that limit line of sight into the welding cell. These welding booth curtains can be rolled sideways for solid style or walked through for strip style to gain entry into the welding booth. They are inexpensive, quick to install, and easy to move when needed.

The Industry Standard

3 Styles To Choose From

Welding Booth Strips

Welding booth strip curtains are one of the most common styles of weld cell curtains. They are static mounts and do not need to be rolled back into place once the welder enters the booth.

Welding Booth Curtains

Use a steel tube, wire, or our curtain track to mount these side to side curtains. Welding booth curtains are considered the most economical of all of the welding dividers due to its simple design and quick installation.

Welding Booth Roll Up

A new design in the welding world is the roll up welding booth curtain. Pull down on the strap to lower, and the ratchet holds the safety welding shade in place. Pull the strap again and it rolls up.

Industrial And Educational Uses

Industrial and Manufacturing

Welding is a growing industry and AKON is the leader in providing safety weld curtains to major manufacturing facilities. Unlike trade-schools, manufacturing facilities have a demand for curtains of all shapes, sizes, and configurations to meet demanding production needs. We customize the curtains to your exact requirements.

Colleges And Trade Schools

Welding booths are used in high schools, colleges, and trade schools all over the country. By using the AKON welding vinyl curtains, these training facilities can provide a safe learning and work environment. Regardless of your needs, we can furnish and provide the correct vinyl weld curtains to keep your students or staff safe.

Home Work Shop

For home workshops, welding curtains are crucial to provide a safe and regulated surroundings for your welding efforts. Using AKON welding vinyl curtains will help to shield your workspace from damaging UV rays, spatter, and sparks, so guaranteeing a safe place for your welding operations.

Material Options

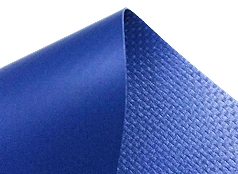

Opaque – 18oz

- Vinyl coated polyester reinforced with scrim

- Meets California Fire Marshal requirements CFM

- Finished edges for clean crisp appearance

- Double or triple hems used where needed for longevity

- All colors are the same price

- 18 oz = .020″ thick, 2.0 oz. per square foot

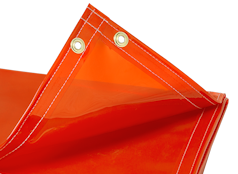

Tinted – 14mil, 40mil

- Ideal for welding applications

- Blocks most UV radiation for welding

- Meets California Fire Marshal requirements CFM

- Finished edges for clean crisp appearance

- Double or triple hems used where needed for longevity

- 14 mil = 14mil thick, 1.44 oz. per square foot

- 40 mil = 40mil thick, 3.95 oz. per square foot

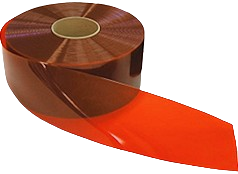

Strips – 8",12"

- Ideal for welding applications

- Blocks most UV radiation for welding

- Meets California Fire Marshal requirements CFM

- 8" wide strips | .080" Thick (ideal for booths)

- 12" wide strips | .120" Thick

- Studded strip or steel tube mounted

Mounting Options

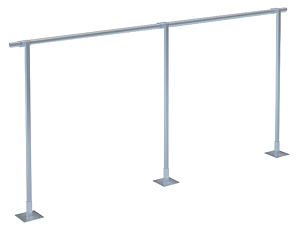

Free-standing

If you have no structure to attach to, then you can use the upright floor columns for up to 15′ in height. Ideal when ceiling hanging hardware options cannot be used or are not ideal. The 16 gauge galvanized steel hardware is designed for rugged industrial use and is quick to deploy and to take down if need be. Depending on the height required, 2″ or 3″ OD tubular steel is utilized. Bolt together design allows for modifications in the future should your welding work cell needs change. The welding curtains can be static zip tied to the frame or rolling curtain hooks.

Curtain Track

The curtain can be hung using steel tracks with roller hooks. This allows the curtain to be rolled out of the way when not needed. It also allows for easy material flow into and out of work areas. Even if the curtains do not need to roll, this method is very efficient and gives the installation a very clean look. Choose from 5 different mounting styles based on the structure you are attaching to.

S- Hooks

If you have a metal bar, tube or steel sire already in place, then simple S-hooks are a common method for hanging a retractable welding curtain shade. They are available in 1" and 2" sizes.

Wall Mount End Stops

This style uses the same rolling track, as shown, above but is supported only from the left and right sides of the track. The end stops anchor to a vertical surface and eliminate the need to support the track from above, below or in the middle. This design allows the curtains to span up to 8'.

Frequently Asked Questions

Welding booths keep workers safe by containing bright arc flash and flying sparks within a defined work cell instead of exposing the entire shop floor. Vinyl welding booth curtains create the same protective enclosure at a fraction of the cost while allowing flexibility to reconfigure or move booths around. Trade schools use these to separate student welding stations, manufacturers install them on production floors, and home workshops set them up in garages. The curtains come in solid panels that slide on tracks, strip curtains that workers walk through, or roll up versions that pull down when welding starts. This FAQ covers which curtain style works best for different traffic patterns, whether the materials actually meet welding safety codes, and how mounting options affect booth flexibility.

Welding Booth Curtains – Frequently Asked Questions

What are welding booth curtains used for?

Welding booth curtains are used to define welding work zones and protect adjacent areas from welding arcs, sparks, UV flash and airborne debris while enabling safe operation and supervision.

What materials are welding booth curtains made from?

They are typically made from flame-retardant vinyl or PVC materials, often tinted in amber, red or green to filter UV and arc flash, and embedded with reinforced fibers for durability.

Are welding booth curtains flame-resistant?

Yes, welding booth curtains meet flame-retardant industrial standards such as NFPA-701 and are built to resist heat, slag and welding spatter in fabrication environments.

Do welding booth curtains reduce UV and arc flash exposure?

Yes, tinted welding curtain materials help block UV rays and arc flash, protecting workers and equipment in adjacent areas from harmful exposure.

Can welding booth curtains be customized for my space?

Yes, they can be customized by width, height, color tint, material thickness, window openings, and mounting hardware to fit specific booth or cell layouts.

How are welding booth curtains installed?

Installation options include ceiling-mounted tracks, wall brackets, cable suspension or mobile frames. Proper installation ensures smooth curtain movement and safe welding zone containment.

Do welding booth curtains include clear viewing panels?

Yes, many models offer clear vinyl or polycarbonate window inserts to allow visibility, supervision and light transmission while maintaining barrier protection.

Can welding booth curtains withstand heavy fabrication use?

Yes, they are designed for high-traffic, industrial fabrication settings and resist frequent movement, welding sparks, heat and spatter for long-term use.

Are welding booth curtains suitable for outdoor use?

Yes, when specified with UV-stable vinyl and corrosion-resistant hardware, they can be used in semi-outdoor or covered fabrication zones.

Do welding booth curtains help reduce noise?

They provide some acoustic isolation by separating noisy welding cells from adjacent work areas, contributing to improved facility ergonomics and comfort.

Can welding booth curtains improve workflow efficiency?

Yes, clear zoning with welding booth curtains helps organize work cells, control access, reduce interference and enhance operational flow in fabrication areas.

Are replacement panels available for welding booth curtains?

Yes, individual curtain panels, window sections and mounting components can be replaced without removing the full system, saving cost and downtime.

Do welding booth curtains support mobile or modular layouts?

Yes, many systems support modular panel setups or mobile track bases, allowing flexible re-configuration of welding work zones as needs change.

Are welding booth curtains compatible with exhaust systems?

Yes, they integrate with welding exhaust and ventilation systems by creating defined zones that help direct airflow and contain fumes near the source.

How much maintenance is required for welding booth curtains?

Maintenance is minimal: periodic cleaning of vinyl surfaces, inspection of tracks/hardware, and replacement of damaged panels when required to extend service life.

Can welding booth curtains help with safety compliance?

Yes, they support compliance with OSHA and ANSI standards for welding safety, arc flash protection, eye-hazard separation and zoning within fabrication facilities.

What are typical sizes for welding booth curtains?

Typical widths range from 8 to 20 ft or more, with heights from 6 to 16 ft or custom sizing available to match facility configurations and booth openings.

Do welding booth curtains protect adjacent equipment and personnel?

Yes, they shield nearby machines, tooling, and workers from welding spatter, heat and UV exposure, reducing maintenance needs and increasing safety margins.

How long do welding booth curtains last?

With proper use and maintenance they typically last 5–10 years or more in industrial fabrication environments, depending on exposure and frequency of use.

Are welding booth curtains available in alternative materials like mesh or strip?

Yes, besides solid vinyl, options include strip curtains, mesh-reinforced panels or perforated versions depending on visibility, containment and ventilation needs.