OVERVIEW

Welding curtain walls are generally used to cover larger areas that portable welding screens cannot. These curtains are fabricated from welding Vinyl, which are fully fire retardant and will reduce the harmful UV rays from welding. The curtain walls come in any size and shape as they are made to order, ranging from extremely small to hundreds of feet tall.

Designed For Speed and Flexibility

Welding Curtain Wall Benefits

Industrial welding curtain walls are designed to resist flying sparks from arc welding and grinding operations while still providing a line of sight from both sides of the curtain.

- Create a safe work area

- Protection shields others from bright arcs and sparks

- A quick solution for dividing work areas

- Improves efficiency by defining work areas

- Can be taken down and reused in other locations

Welding Curtains for Safety

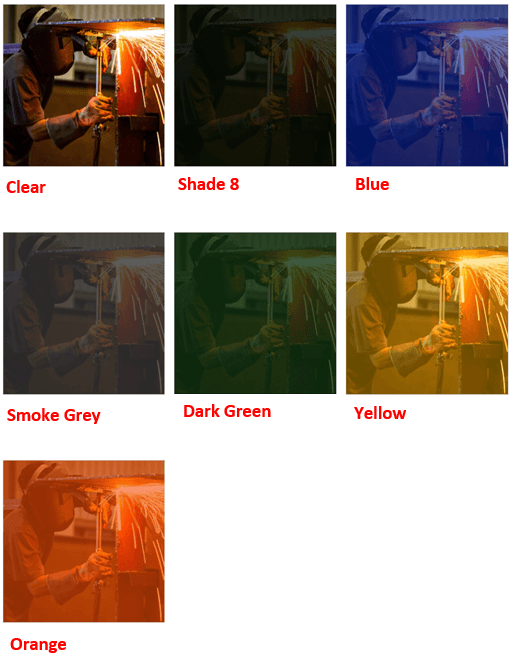

AKON premium welding curtains allow you to meet all required safety regulations. This line of sight is tinted with a UV blocking film to help protect your eyes from indirect viewing.

- Flame resistance as required by (NFPA-701, CFM, ATSM E-84 class I)

- 5 year warranty on all Manufacturing defects

- All designs are OSHA approved welding curtains

- Welding and spark resistance

- Made in the USA

Make Any Layout You Want

Easy Install

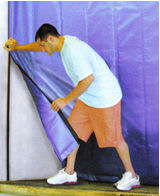

Welding curtain walls come with grommets at the top, making hanging the welding curtains quick and easy with or without the curtain track.

Welding Certified

AKON welding vinyl walls are certified for welding operations with fire retardant ratings and UV reducing properties.

Protects Welders

Hanging welding curtain walls are ideal for protecting welders from arc flash and sparks that present a safety hazard.

Control Noise

The tinted PVC welding curtains help protect your eyes from welding UV rays and reduce noise due to the thick PVC they are made from.

Welding Fume Capture Enclosures

Capture Fumes From Floor to Ceiling

An efficient way to restrict welding fumes inside designated areas and stop them from permeating a whole facility is using vinyl curtain walls running floor to ceiling. Durable, fire-resistant vinyl material makes these curtains able to survive the intense heat and sparks connected with welding operations. These curtain walls help to separate welding fumes by building a physical barrier, therefore ensuring their confinement to the intended welding region. Maintaining air quality throughout the remainder of the plant depends on this, which also shields workers from harmful pollutants.

Keep Your Facility Clean

Apart from fume control, vinyl curtain walls provide simplicity of installation and versatility. Usually mounted on rails, they may be readily retracted or relocated as necessary and are custom-sized to meet any workstation. Their versatility makes them perfect for dynamic offices where the layout might be changed often. Moreover, by reducing the spread of airborne pollutants and so enhancing general worker safety, these curtain walls enable facilities to follow safety rules.

Use With Welding Strip Curtains

Combination Uses

For machine guarding, combining welding strip curtains with welding curtain walls provides maximum safety and protection in industrial settings. While the strip curtains offer a flexible answer for guarding machines, the curtain walls act as a solid barrier to contain sparks, splatter, and harmful gasses. Strip curtains shield surrounding equipment and workers from debris and welding byproducts escaping the immediate area. This arrangement also increases general safety by lowering the possibility of unintentional machine interaction. Taken together, they provide a thorough and compliant approach for controlling risks and guaranteeing a safer workplace near welding activities.

Choose From Many Configurations

Hanging Welding Curtains

Hanging welding curtains can be used to isolate individual or multiple welding booths, or simply as a single dividing welding wall. AKON can take your design and make the hanging welding curtains into almost any configuration, depending on what you need. When your curtains are hung from above, retracting them grants you a completely open space. They also have the ability to roll around the corner, utilizing radius corners.

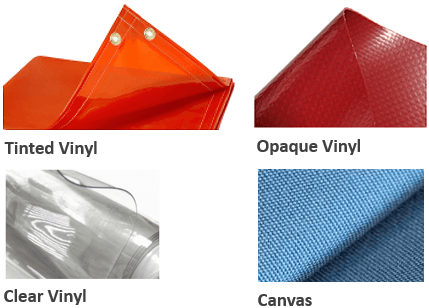

Material Options

There are three different material options for the vinyl welding curtain walls. These include an opaque non-see-through material and a tinted material which allows limited line of sight through the curtains. The tinted material is a 14mil welding grade vinyl and the opaque material is an 18oz welding grade vinyl. You can also choose canvas welding curtains, better known as hot works welding curtains, for close proximity heavy welding.

Complete Containment Solution

Frequently Asked Questions

Welding operations throw off bright UV light and flying sparks that damage eyes and injure nearby workers who are not even doing the welding. Portable welding screens work fine for small jobs, but larger fabrication areas need full curtain walls that cover entire work zones from floor to ceiling. The fire retardant vinyl handles sparks without catching fire or melting through like regular curtains would. Facilities use them to create permanent welding booths or hang them on tracks that slide back when the space needs opening up. This FAQ covers whether the tinted material actually protects eyes from UV damage, how the fire rating compares to safety requirements, and what mounting options work best for different shop layouts.

Welding Curtain Walls – Frequently Asked Questions

What are welding curtain walls used for?

Welding curtain walls are used to divide workspaces, protect surrounding areas from welding arcs, sparks, UV radiation, and hot materials. They enable safe zoning of welding operations while maintaining visibility and workflow.

What materials are welding curtain walls made from?

These curtains are typically fabricated from flame-retardant vinyl or reinforced PVC, often tinted (red/amber) to filter UV light and protect personnel from welding glare and spatter.

Are welding curtain walls flame-resistant?

Yes, welding curtain walls are designed with flame-retardant materials that comply with industrial safety standards, helping reduce fire risk in welding environments.

Do welding curtain walls block UV and arc flash?

Yes, when tinted properly, these curtain walls filter harmful UV rays, arc flash and bright welding light, improving safety and comfort in surrounding areas.

Can welding curtain walls be customized?

Yes, they can be tailored in size, height, width, material thickness, color tinting, window visibility panels, and mounting hardware to suit specific facility layouts.

How are welding curtain walls installed?

Installation usually involves ceiling-mounted tracks, wall brackets or cable suspension. Proper installation ensures smooth curtain movement and secure containment of welding zones.

Are clear view panels available in welding curtain walls?

Yes, clear vinyl or polycarbonate vision panels can be integrated to allow supervision and light transmission without compromising welding zone protection.

Do welding curtain walls withstand heavy duty use?

Yes, industrial-grade welding curtain walls are built for high traffic, repeated opening/closing, and exposure to sparks and heat, making them suitable for fabrication shops.

Can welding curtain walls be used outdoors?

Yes, if specified with UV-resistant vinyl and corrosion-resistant hardware, welding curtain walls can be installed in covered outdoor fabrication zones or semi-open areas.

Do welding curtain walls reduce noise?

Yes, they offer moderate noise dampening by creating a barrier between welding operations and adjacent work areas, helping improve overall facility acoustics.

Can welding curtain walls improve workflow?

Yes, by dividing zones and delineating safe work areas, welding curtain walls help streamline workflow, control access, and enhance overall productivity in the fabrication area.

Are replacement panels available for welding curtain walls?

Yes, individual curtain panels and mounting hardware can be replaced without full system removal, making repairs fast and cost-effective.

Do welding curtain walls support fixed or mobile layouts?

They support both stationary installations and mobile setups with track systems or removable panels, allowing flexible reconfiguration of welding zones.

Are welding curtain walls compatible with welding exhaust systems?

Yes, they are designed to integrate with fume extraction and ventilation systems by creating defined zones which help direct airflow and contain welding contaminants.

How much maintenance do welding curtain walls require?

Minimal maintenance is needed: routine cleaning, inspection of curtain tracks and hardware, and occasional curtain replacement. Proper care extends lifespan significantly.

Can welding curtain walls help with safety standards compliance?

Yes, using welding curtain walls supports compliance with OSHA and ANSI standards concerning welding safety, arc flash protection, and hazard zoning.

What sizes are typical for welding curtain walls?

Typical widths range from 8 ft to 20 ft or more, with heights from 6 ft to 16 ft or custom heights, depending on facility and equipment requirements.

Do curtain walls help protect adjacent equipment?

Yes, they shield machinery, tooling, and nearby workstations from weld spatter, heat damage, and debris, reducing maintenance and downtime.

How long do welding curtain walls last?

With proper use and maintenance, welding curtain walls typically last 5–10 years or more in industrial settings, depending on exposure and usage frequency.

Can welding curtain walls integrate lighting and visibility?

Yes, they can include translucent or clear panels, lighting accommodations, and visibility strips to maintain natural light and supervision while maintaining the barrier.

Photo Gallery

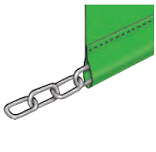

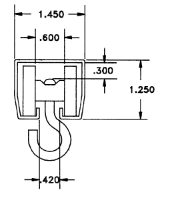

Rolling Hardware

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.