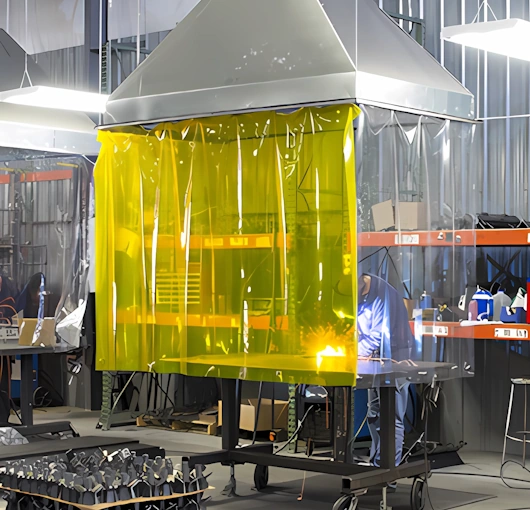

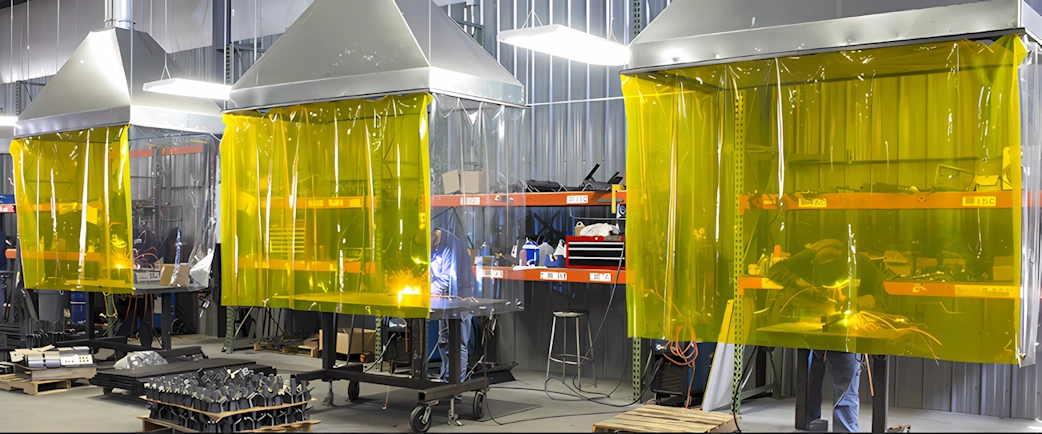

Description

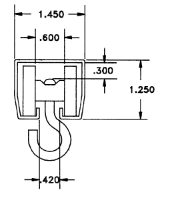

Hardware

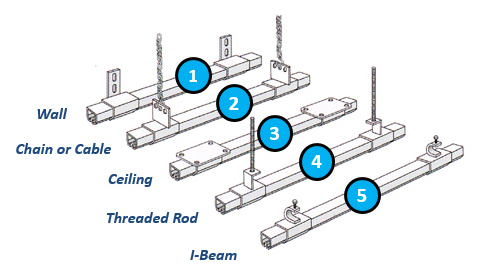

Curtain Track

- 16-gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 5 mounting styles to connect to various structures

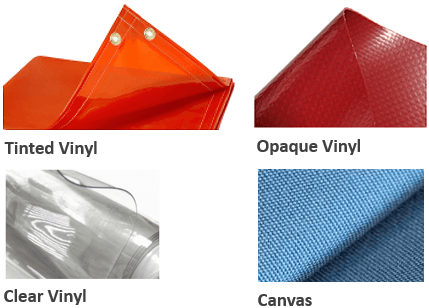

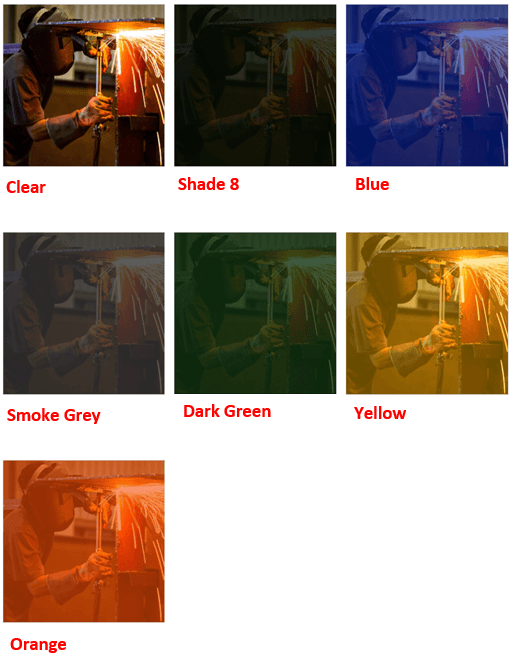

Curtains

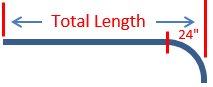

How to Measure

Benefits