OVERVIEW

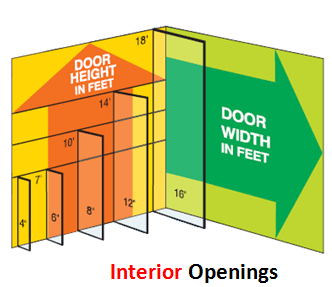

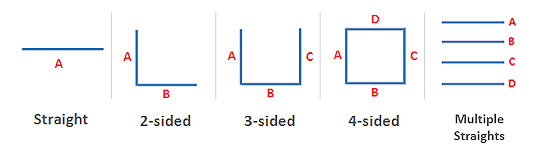

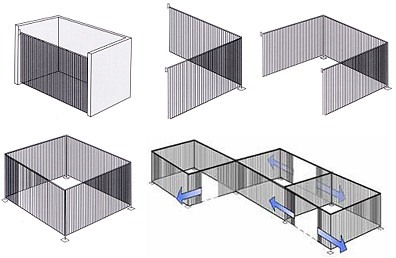

Free standing pvc strip curtain enclosures are a great way to fully enclosure a work area while still allowing foot traffic and material rapid access. These strip curtain enclosures can be 1,2,3 or 4 sided and also can feature ceiling curtains if complete containment is required.

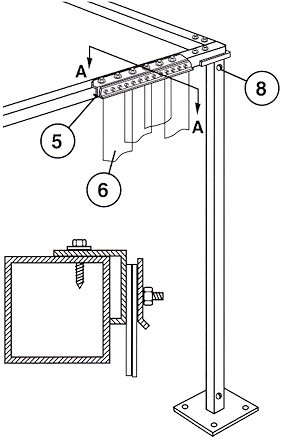

Rugged Industrial Hardware

Strip Hardware

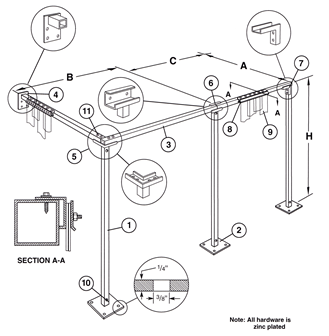

Using the same studded hardware as a traditional strip curtains, the welding strips attach to the galvanized steel frame and securely bolt on. This prevents the strips from coming detached when material moves through. The hardware is fabricated from hot dipped galvanized steel which also comes with a life time warranty.

Modular Design

Choose from a simple single sided design or choose to make many different individual strip curtain booth enclosures. The hardware is designed to bolt together quickly in the field which allows for almost any design. With each order you will also receive a layout drawing so that you can verify your layout before production.

Welding Applications

Strong barriers meant to produce safe, contained workplaces for welding operations are free-standing welding curtains. Built from flame-retardant materials such as vinyl, these curtains successfully prevent generated spatter, UV rays, and sparks from welding. Free-standing welding curtains are perfect for places where overhead support is neither practicable. They are hung on strong, fixed frames unlike hanging curtains that call for overhead support. They lower fire hazards, assist to manage welding fumes, shield surrounding people and equipment from dangerous exposure, and thus protect welders. Without depending on ceiling-mounted equipment, these free standing curtains are especially appropriate for permanent or semi-permanent setups in industrial situations since they provide safety and compliance in welding activities.

Frequently Asked Questions

Free standing strip curtains support from the floor up when hanging from the ceiling just does not work or creates too many complications. The galvanized steel frame creates enclosures anywhere on the floor without drilling into roofs or structures overhead. Strips allow workers and forklifts to pass through constantly without opening doors or pushing curtains aside, which keeps work flowing smoothly. Facilities build one-sided barriers or complete four-sided enclosures depending on what the space needs. The bolt-together design means these move or reconfigure when layouts change. This FAQ covers whether base plates need anchoring down, how stable these stay with heavy forklift traffic, and what maximum height actually works without tipping issues.

Free Standing Strip Curtains FAQ

What are free standing strip curtains?

Free standing strip curtains are modular, floor-mounted PVC or vinyl strip curtain systems mounted on their own steel frame rather than from the ceiling. They create flexible enclosures, work zones or material access points without needing overhead structural support.

Why choose a free standing strip curtain instead of ceiling mounted?

Because in many industrial spaces there may be no overhead beam or the ceiling may be used for crane rails. A free standing option gives you a self-supporting frame so you can install strip curtains where overhead mounting isn’t possible or practical.

What materials are used in free standing strip curtains?

Typically, they use flame-retardant PVC strip curtains mounted on a galvanized steel frame. The strips are available in clear, tinted or opaque versions, and the frame is often hot-dip galvanized for durability in industrial environments.

Can these curtains create full enclosures or just one side?

Yes, they can create full 1-, 2-, 3- or 4-sided enclosures depending on your layout. The modular design allows you to bolt together multiple straight sections or right-angle sides to build complex configurations around work cells or equipment.

Are replacement strips available for free standing systems?

Yes, you can replace individual strips without replacing the entire system. This helps reduce long-term maintenance cost and keeps your enclosure functioning effectively by replacing worn, torn or discoloured strips as needed.

How easy is installation?

Installation is straightforward: assemble the steel uprights and base plates, bolt on the horizontal track, then hang the strips from the track. Because it is free standing, you don’t need overhead attachments — making it faster to install in many cases.

Can free standing strip curtains handle heavy traffic?

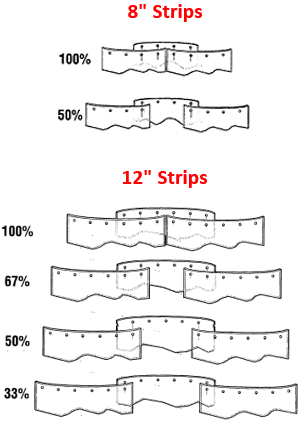

Yes — depending on strip width/thickness, you can select versions for foot traffic, pallet trucks or forklift traffic. For example, wider and thicker strips provide more durability for material handling applications, while narrower strips suit personnel access.

Do they help with containment of dust, sparks or spray?

Yes, free standing strip curtains help contain dust, flying debris, overspray and even some welding spatter in an industrial environment. They create a soft barrier that allows quick access while improving enclosure control and separation of work zones.

Are these systems mobile or anchored?

They are typically floor mounted and can be anchored for stability, especially for higher or larger enclosures. Some systems offer optional casters or wheels for mobility, but anchoring is recommended for heavy duty or crane-accessible zones.

Can I customize the size, color and layout?

Yes — free standing strip curtain systems are highly customisable. You may specify width, height, number of sides, strip colour (clear, bronze, blue, red), strip width/thickness, and frame layout to fit your facility design and traffic requirements.

Do these systems meet fire and safety standards?

Yes — the PVC strips are typically rated to CFM and NFPA-701 flame retardant standards, and the steel frame is designed for industrial use. When installed correctly, they help meet separation and containment requirements in manufacturing settings.

How do I maintain the system?

Maintenance involves inspecting the strips for wear or tear, checking the frame and base plates for secure anchoring, cleaning the strips to maintain clarity, and replacing damaged strips to maintain performance and safety.

Can they be used outdoors or in wet environments?

While the frame is often hot-dip galvanized for corrosion resistance, most free standing strip curtains are designed for indoor environments. For outdoor or wash-down zones, you should ensure strips and hardware are rated for the conditions.

What is the typical lead-time for these systems?

Lead-time varies by size, customisation and material availability. Standard configurations may ship quickly, while fully customised layouts or large-scale enclosures may require longer manufacturing and shipping times.

How long will a free standing strip curtain system last?

With proper installation and maintenance, these systems can last many years. Key factors include traffic volume, environmental conditions, strip material thickness and maintenance schedule — replacing worn strips extends lifespan.

Can overhead cranes work above free standing strip curtains?

Yes — because the system is floor mounted, the overhead space remains clear for cranes, hoists or material handling systems. This makes them ideal for manufacturing zones where ceiling clearance is required for other equipment.

Are free standing strip curtains cost-effective?

Yes — compared to building rigid walls or full enclosures, free standing strip curtain systems offer a lower-cost solution with fast installation, flexible configuration and access advantages, while still providing separation and containment benefits.

What industries use free standing strip curtain enclosures?

Industries such as welding fabrication, assembly plants, warehouse operations, automotive manufacturing, spray booths and metal processing use free standing strip curtain systems to provide flexible enclosures, zone separation and safety barriers.

How do I choose strip width and thickness?

Consider traffic type: For personnel only, narrower strips (e.g., 8″ width, .080″ thickness) are suitable; for pallet or fork-truck traffic, wider (12″) and thicker (.120″) strips are preferable. Overlap should be selected based on volume and speed of traffic.

Photo Gallery

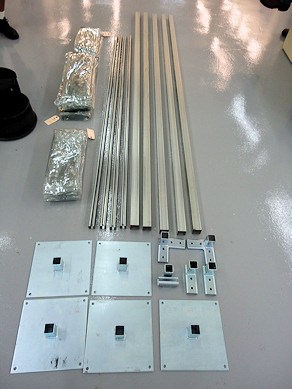

Construction

- Galvanized steel - Hot-dip galvanizing (HDG)

- Lifetime warranty

Uprights

- 2" x 2" OD tubes

- Tube size selected based on curtain heights

- Max height is 12'

- Maximum distance between uprights is 8′

- Layout drawing provided with each order for your

approval

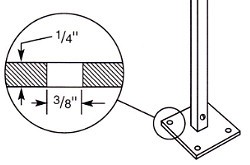

Base Plates

- 12" x 12"

- 3/8" lag holes located in each corner

Assembly

- Your order will arrive as a bolt together kit

- Simply assemble hardware and then hang the strip curtains

Strip Mount Style

- Strips attach to horizontal cross members

- Strips bolt on for secure locking

- Strips can unbolt to be replaced quickly