OVERVIEW

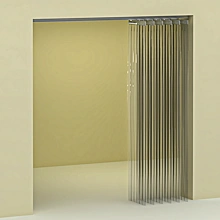

Preventing the loss of cold air from your cooler or freezer reduces your energy bill while keeping your food or beverages cold. Using a walk-in cooler curtain or a walk-in freezer door curtain will eliminate this expensive air loss. The freezer door flaps hold the cold air in and prevent warm air from entering. The doors also meet the Energy and Security Act of 2007 which requires strip doors on all new walk-in coolers and freezers.

Strip Kits

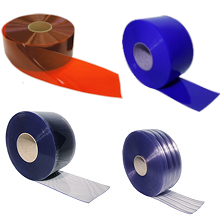

Replacement | Bulk Rolls

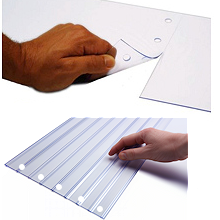

Replacement Strips

Precut and punched strips that are ready for hanging.

PVC bulk rolls with no cuts or punches. You cut and punch the strips onsite.

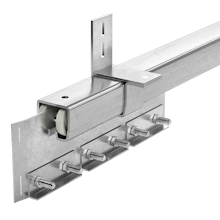

Specialized Mounts

Hardware

This bracket allows for strip installation that is about 75% quicker than traditional metal track styles. Not for 16" wide strips.

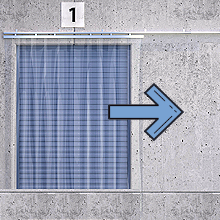

Rolling door hardware allows the strip door to be moved out of an opening when needed.

Applications & Codes

Code Requirements

The USDA passed the onus of compound compliance/approval to be under FDA provisions, specifically Title 21 CFR (Code of Federal Regulations). Since the USDA does not approve equipment or materials, we have material that meets CFR 21, which ensures that the compounds used are FDA certified raw materials. The AKON curtains are Title 21 CFR compliant and carry a UFL-94 Fire Cert.

Code Requirements

In the past, the USDA examined the composition of materials and gave "letters of no objection" to those that were judged suitable chemically for the intended use. There is no longer any use for this protocol. To make sure the materials are of a high quality the Title 21 CFR is followed.

Code Requirements

Our PVC strip curtains are meticulously designed to meet the stringent requirements set by the Canadian Food Inspection Agency (CFIA), ensuring optimal performance in hygiene-critical environments. They provide a reliable, durable solution for maintaining temperature control and cleanliness in food processing areas.

Cooler and Freezer Usage

Quick Installation

Both styles of mounting hardware are very quick to install. Only basic tools are required to attach the hardware to the freezer or cooler. The studded hardware hangs the strips on studs with lock nuts. The tube mount style only requires a few screws on the right side and the left side of the opening.

Save Energy

Free flowing air in a controlled temperature zone is the number one cost for most food processing facilities and retail outlets. The freezer flap doors eliminate this unnecessary expensive and are one the of the quickest solutions to install. With an excellent ROI and ability to fit almost any opening, these clear food grade strips are found in almost all facilities with coolers and freezers.

Low Temp PVC Strips

The unique composition of the low temp strips stays flexible to -20° F and the standard strips stay flexible to 0° F. The PVC material is nonporous making for an extremely slick surface. This is ideal as it helps prevent bacteria buildup. Standard grade PVC comes in 6” and 8” widths. Low-temperature PVC comes in 6” and 8“ widths.

Key Benefits

Benefits of Using a Strip Curtain on Your Cooler

There are many advantages to using strip curtains on coolers, especially in commercial and industrial environments where energy economy and temperature control are critical. All things considered, strip curtains are a useful and effective way to preserve temperature control, boost energy efficiency, and guarantee the integrity of stored items in colder climates. The following are some of the main benefits:

- Energy Efficiency: By reducing the quantity of cold air that leaves when the door is opened, strip curtains assist keep the cooler's temperature stable. Lower energy expenses result from using less energy to maintain the cooler's temperature.

- Temperature Control: They act as a barrier to help maintain a steady interior temperature, which is necessary to maintain perishable goods' quality. Strip curtains contribute to the maintenance of ideal conditions needed for the storage of food, medications, and other temperature-sensitive goods by preventing the entry of warmer air from the outside.

- Cost-effective: Strip curtains are a less expensive solution for controlling temperature than solid door installation. They are more affordable because they are simple to install and maintain.

- Simple Access: Without requiring employees or equipment to physically open a door, strip curtains make it simple for them to reach the cooler. Because it cuts down on the time needed to open and close doors, this is especially helpful in busy areas where operational efficiency is increased.

- Reduced Condensation and Ice building: Strip curtains can aid in preventing condensation and ice building around the cooler entry by preserving constant temperatures and minimizing the exchange of humid outside air with the dry, cool air within. This lowers the risk of slips and falls, making the workplace safer.

- Better Air Quality: By keeping dust, bugs, and other impurities out of the cooler, strip curtains can help keep the inside air purer. This is important in situations when the quality of the kept goods is impacted by the air purity.

- Versatility: Strip curtains can be used in a variety of settings, including those with harsh temperatures or hygienic requirements, because they are available in a range of materials and grades.

- Reduction of Noise: They can also aid in attenuating noise, resulting in a more comfortable and silent workplace, particularly in hectic industrial situations.

Frequently Asked Questions

Strip doors for coolers and freezers keep cold air where it belongs while letting people and equipment pass through freely. The overlapping plastic strips create a barrier that holds temperatures steady without anyone needing to open and close traditional doors constantly. Restaurants, warehouses, and food processing facilities rely on them to cut energy costs and maintain consistent cooling. Different strip thicknesses handle varying temperature ranges, and most doors mount quickly to existing doorframes. This FAQ covers how to choose the right strip width and thickness, whether these work in extreme freezer temperatures, and what kind of energy savings to expect over time.

Cooler and Freezer Strip Doors FAQ

What are cooler and freezer strip doors used for?

These strip doors help maintain temperature inside walk-in coolers and freezers. They reduce energy loss when staff move in and out while still keeping the entry accessible.

How do these strip doors help with temperature control?

They create a flexible barrier that keeps cold air in and warm air out, improving efficiency and lowering energy costs for refrigerated areas.

Are the strips USDA compliant?

Yes, the PVC materials are USDA-compliant and suitable for food-safe environments such as kitchens, storage rooms, and food processing areas.

Can I use these strip doors in high-traffic areas?

Yes, they are designed for heavy foot traffic and cart movement. The strips move easily while staying durable under frequent use.

Do the strips become stiff in cold temperatures?

No, they are made from low-temperature PVC that stays flexible even in freezing environments, preventing cracking or tearing.

How thick are the strips?

Strip thickness commonly ranges from 6 to 12 millimeters depending on the application and level of durability needed.

Are the strips clear or tinted?

They are available in clear and frosted options. Clear strips provide high visibility for safety in busy cooler environments.

Can these strip doors reduce frost buildup?

Yes, they help minimize warm air infiltration, reducing frost and ice buildup on equipment inside the cooler or freezer.

How do I install cooler and freezer strip doors?

They mount to a header or door frame using a steel or aluminum bracket. Installation is straightforward and requires basic tools.

Can damaged strips be replaced individually?

Yes, each strip can be replaced without removing the entire door, saving time and maintenance costs.

What widths do the strips come in?

Typical widths include 6", 8", 12", and 16". Larger widths are often used for freezers or heavy industrial use.

Do the doors help reduce noise?

Yes, PVC strips help soften noise from equipment and traffic moving in and out of the cooler or freezer.

How do I clean the strips?

Simply wipe them with warm water and a mild cleaner. They resist staining and remain clear with routine cleaning.

Do strip doors help reduce condensation?

Yes, by limiting warm air exposure, they reduce moisture and condensation that commonly forms in freezer areas.

Are these strip doors safe for food storage areas?

Yes, they are food-grade and safe for use in any environment where food is stored or handled.

Can I customize the strip length?

Yes, strips can be cut to fit the exact height of your cooler or freezer opening for optimal performance.

Do they work with pallet jacks and carts?

Yes, the flexible strips allow equipment to pass through without damage while still keeping cold air inside.

How long do the strips typically last?

With regular use, low-temperature strips usually last several years before needing replacement.

Can these be used on walk-in freezer doors that stay open?

Yes, many kitchens use strip doors as a secondary barrier when the main door is left open during busy hours.

Do you offer hardware for mounting the strip doors?

Yes, complete hardware sets including brackets and fasteners are available for quick installation.