OVERVIEW

USDA Strip Curtain Curtains and Doors are made up of compounds that meet federal requirements for incidental contact with meat, poultry and dairy products. They meet USDA, NSF, CFIA-ACIA, and FDA requirements.

Quick Entry & Exit

Quick Access Without Opening

USDA, FDA and CFIA food processing strip curtains and doors allow quick access between food packing lines or doorways. Unlike the AKON solid curtain USDA curtains which roll side to side on a curtain track, the strip curtains you can walk through. This allows for quick access for people and products.

Update

The USDA passed the onus of compound compliance/approval to be under FDA provisions, specifically Title 21 CFR (Code of Federal Regulations). Since the USDA does not approve equipment or materials, we have material that meets CFR 21, which ensures that the compounds used are FDA certified raw materials. The AKON curtains are Title 21 CFR compliant and carry a UFL-94 Fire Cert.

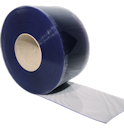

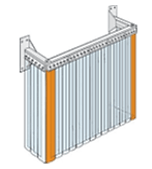

Mounting Options

Mounting Options

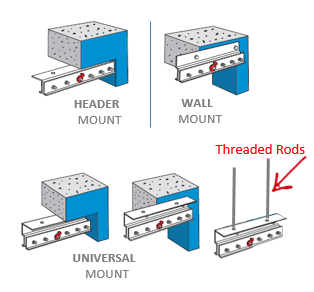

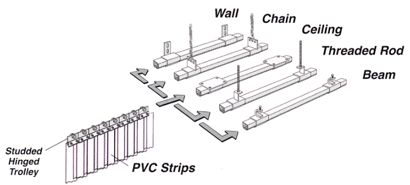

Fixed Mounts - This hardware is the most common and can mount to existing structure or be supported from above with threaded rods.

Free-Standing - If it is not possible to attach to existing structure or hang the strips from above and you can use floor mounted hardware. 12' is the maximum allowed height for the freestanding style.

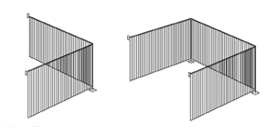

Sliding Tracks - If you have enough space, you can use the rolling hardware which will allow the strips to be moved completely out of the way. Keep in mind, if you have a 10 foot strip curtain, you'll need 20 feet of track to move it completely out of the way. You can also use a radius corner to make an L-shape to store the food grade strip curtain off to the side.

USDA Strip Curtain Wall Uses

PVC Rated For USDA and CFIA Use

- UV stabilized

- Meets California Fire Marshall codes

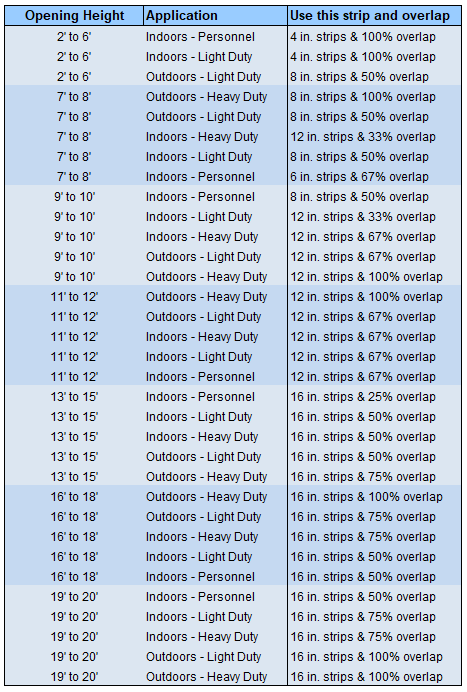

- Strips are overlapped to prevent cross spray

- Quick to hang pre-punched strips

- Static mount strips or rolling strips for clearance

- Easy to replace damaged USDA Strips

- USDA temp strip curtains are rated for -20 F

- USDA low temp strip curtains are rated for -40 F

Common Applications

- Walk-in coolers

- Refrigeration divider walls

- Stockroom storage strip curtain walls

- Forklift traffic divider

- Food processing facility divider

- Sanitation strip curtain divider for wash down

- Clean room strip curtain partitions

Frequently Asked Questions

USDA strip curtain walls are a practical solution for maintaining cleanliness and order in food processing environments. These curtains offer a simple way to manage temperature, dust, and humidity, all while allowing easy access for workers. The vinyl's surface is easy to clean, and it endures regular maintenance without issue. These curtains also serves as a divider in a facility to ensure safe and efficient productivity. This FAQ talks about basic information on the curtains' functionality, their applications, and proper maintenance.

USDA Strip Curtain Wall – Frequently Asked Questions

What is a USDA strip curtain wall?

A USDA strip curtain wall is a vinyl or PVC barrier designed to meet USDA sanitation requirements by separating processing areas, reducing contamination, and allowing easy cleaning in food and pharmaceutical facilities.

Where are USDA strip curtain walls typically used?

They are commonly used in meat processing plants, dairies, packaging rooms, sanitation zones, and other areas requiring strict hygiene and contamination control.

Do USDA strip curtain walls meet food safety requirements?

Yes, they are made from FDA- and USDA-compliant materials with smooth, non-porous surfaces that resist bacteria, moisture, and chemical exposure.

What materials are USDA curtain walls made from?

They use clear or tinted PVC, vinyl, or USDA-grade smooth materials designed for easy wash-down, resistance to chemicals, and long-term durability.

Are these curtain walls easy to clean?

Yes, the smooth non-porous surfaces allow simple wash-down with approved sanitizers, making daily or frequent cleaning efficient in USDA facilities.

Do USDA strip curtain walls help control contamination?

Yes, they act as a physical barrier that reduces cross-contamination by limiting airborne particles, temperature mixing, and traffic flow.

Can USDA strip curtain walls be customized?

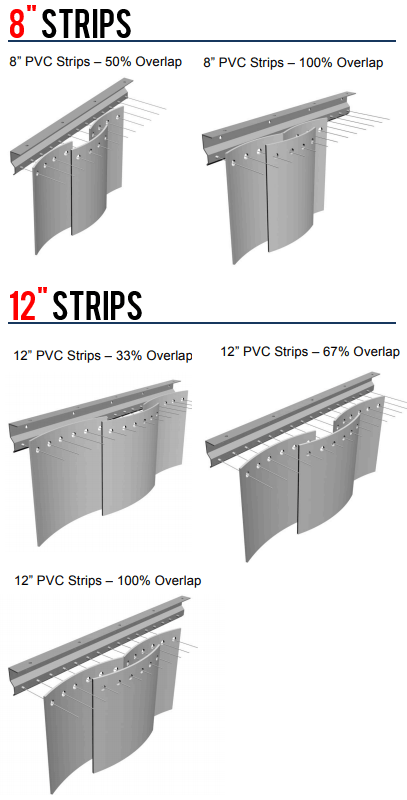

Yes, custom sizes, strip widths, overlap percentages, and mounting options are available to fit any processing line or sanitation zone layout.

Do these curtains help maintain temperature zones?

Yes, the overlapping strips help improve temperature retention by minimizing warm or cold air exchange between controlled rooms.

Can USDA strip curtain walls be used in wash-down areas?

Yes, they are designed for full wash-down, high-moisture, and chemical-cleaning environments where sanitation is essential.

Are replacement strips available?

Yes, individual strips can be replaced at any time without removing the entire curtain, keeping maintenance cost-effective.

How are USDA curtain walls mounted?

They mount using stainless-steel or corrosion-resistant hardware on ceilings, walls, or frames depending on the application and access needs.

Do USDA strip curtains reduce workflow interruptions?

Yes, they allow personnel and carts to pass easily while still maintaining separation, reducing the need for rigid doors or partitions.

Are USDA strip curtains resistant to chemicals?

Yes, the materials are formulated to handle sanitizers, detergents, and harsh cleaning agents used in USDA-regulated environments.

Can these curtains be used alongside rigid USDA walls?

Yes, they integrate well with rigid wall systems to create hybrid sanitation zones with flexible access points.

Do they help reduce dust and airborne contaminants?

Yes, the overlapping PVC strips act as a barrier to limit dust, aerosols, and debris from entering clean processing zones.

How durable are USDA strip curtain walls?

They are built for long-term industrial use, with high resistance to tearing, chemicals, temperature swings, and moisture exposure.

Are clear visibility strips available?

Yes, clear strips improve line-of-sight for operators while maintaining sanitation and separation requirements.

Do USDA curtains help control odors?

Yes, they help contain odors inside processing areas by reducing air transfer between different work zones.

Can USDA strip curtains be installed quickly?

Yes, modular mounting systems allow quick installation with minimal facility downtime.

Are these curtains suitable for cold storage?

Yes, USDA strip curtains are available in low-temperature PVC formulations suitable for coolers and chilled processing spaces.

Static Mount

- Header Mount

- Wall Mount

- Universal Mount

- Threaded Rod Mount (Just a Feature of Universal Mount)

Free-Standing Mount

- Supported from the floor up

- Used in open floors when you can support from above

Rolling Hardware

- Allow the strips to roll out of the way

- Ideal for complete access when strips are not needed

- Note the strips roll like a barn door and do not fold up

Stand Off Hardware

- Commonly used for roll up drums near dock doors

- Hardware is extendable outwards to accommodate door drum

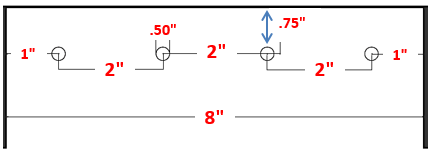

Tube Mount

- Fits up to 2" diameter pipe

- Each pipe clamp is 4” wide and holds 2 strips (overlapped)