OVERVIEW

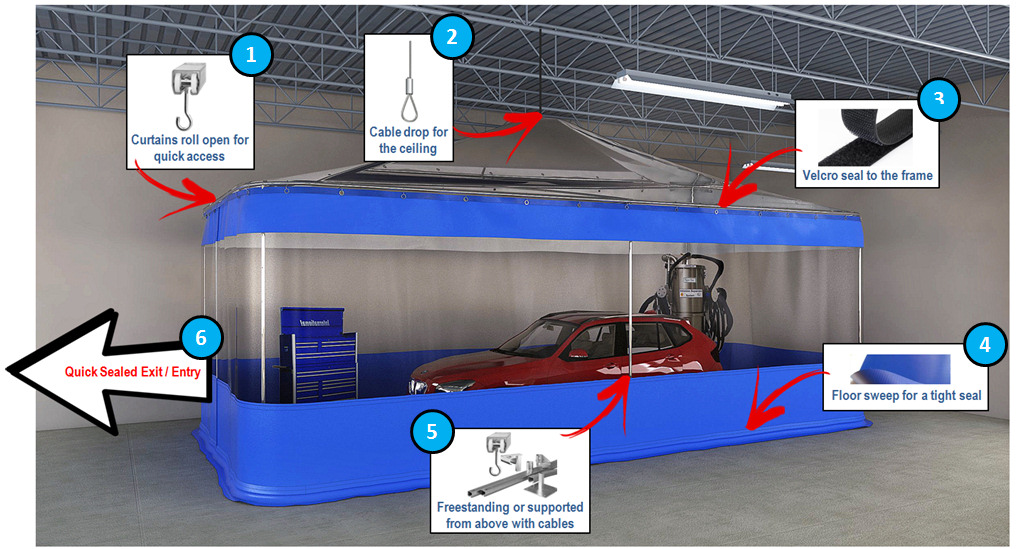

When complete coverage is needed for painting and sanding operations then the AKON automotive paint and sanding station is the solution. These enclosures are large enough for cars and trucks to pull into with enough room around them for equipment and associates to work. Featuring a clear 20 mil reinforced ceiling supported from above with a single cable attached to your existing structure.

The paint prep station provides a contained environment which will allow the rest of your shop to remain clean from overspray and dust created from sanding. It is also an ideal solution to meet new guidelines for aluminum auto body sanding operations.

Designed For Speed and Flexibility

Key Features

#1 – The curtains can roll completely open for quick entry and exit

#2 – A single cable drop from above holds up the clear ceiling

#3 – Velcro is attached on the sides of the curtain track for a complete seal

#4 – A floor sweep engages the floor to contain dust, paint and sparks

#5 – The prep station can be floor mounted or hung from above with cables

#6 – A Velcro or magnet split at one or both ends for vehicle entry and exit

Material Options

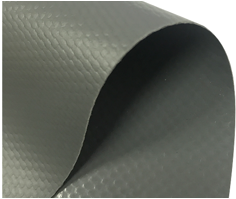

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

The Leader In Curtain Spray Booths

Ideal Applications

- Paint prep station curtains

- Prep booth curtains

- Retractable paint booths

- Detailing Wash Bays

- Under Coat Bays

- Grinding and Sanding Bays

- Under Coating Curtains

- Aluminum Grinding and Sanding Station

Benefits

- Less expensive than rigid walls like drywall and fixed panels

- Allows for different work processes in zoned areas

- Improves air quality and worker conditions

- Easily roll the curtains out of the way when not in use

- The spray paint curtains meet all fire codes and regulations

Easy Install

Painting and sanding enclosures come as a complete kit and are easy to install with no welding required and only basic tools are needed.

Inexpensive

Akon dust enclosures are about 1/3rd of the cost of other separation methods such as rigid walls systems and are easy to store.

Separate Workers

Dust enclosures are ideal for separating workers that are performing dust creating activities from those that are not.

Control Noise

The curtain enclosures are also dual purpose noise control curtains due to the thick vinyl they are made from.

Installation

Installing the prep booth enclosure is quick and very easy. You will find that the track hardware bolts together in a modular fashion and then the roller hooks are inserted. Once the track is assembled and hung you can now easily attach the prep station curtains via the grommets located at the top of the curtain. Then hang the clear ceiling curtain and Velcro its perimeter to the track. Quick and Easy!

Maintaining The Curtains

The automotive paint and sanding station curtains are made from a slick material much like a shower curtain. The material can be easily wiped off when it becomes dusty and washed down when it becomes dirty. If the paint shop curtains become really dirty you can wash them down further with a cleaning agent. The curtain wall material is also mildew proof and resistant to most chemicals. In addition, if they become torn from a sharp object we offer clear patch tape to repair the rips.

Aluminum Dust

Aluminum dust is now part of new car frames and dealing with that dust is a critical consideration for auto body shops. The processing of these aluminum body cars and trucks requires a completely sealed off area. Our aluminum repair enclosure curtains will enclose these work areas where grinding, sanding, and prep work is taking place. Keeping the rest of the shop clean.

Filter Panels

The AKON body shop curtains can also include 4′ x 4′ filter panels to allow for negative pressure generated inside of the curtain enclosure due to ventilation systems. These replaceable curtain filters Velcro onto the curtain and can be replaced if and when they become too clogged to function. They keep your air clean and safe for the environment.

Complete Containment Solution

Frequently Asked Questions

Wash-down curtains for automotive paint and sanding stations offer a flexible and cost-effective way to keep work areas clean and safe. These curtains create a barrier between the sanding or painting zone and the rest of the shop so dust, debris, and overspray stay in the right place. The heavy vinyl material stands up to water, paint mist, and harsh cleaning cycles without breaking down. This FAQ section explains how well the curtains perform, how they mount, and what maintenance they need.

Wash-down Curtains for Automotive Paint & Sanding Station

What are wash-down curtains for paint and sanding stations?

Yes. These curtains are designed to contain water, overspray, sanding dust and debris in automotive body-shop wash and sanding zones, helping protect adjacent areas from contamination and maintaining safety and cleanliness.

How do wash-down curtains compare to permanent partitions?

No. Rather than fixed walls, these curtains offer flexibility, faster installation, and easier reconfiguration—ideal for body shops where layout or operations change frequently.

What materials are used for paint and sanding-station curtains?

Yes. Heavy-duty vinyl or PVC rated for wet or dusty environments, often reinforced and optionally including clear panels to allow visibility while containing spray and dust.

Are these curtains suitable for sanding and paint prep zones?

Yes. They’re built to resist abrasive dust, solvents, water spray and overspray often generated during sanding, prepping and washing in automotive body-shops.

Do wash-down curtains help improve shop safety?

Yes. By isolating wet or dirty zones, containing debris and reducing slips or cross-contamination, they enhance safety and organization in prep and sand areas.

Can these curtains be custom-sized for large bays?

Yes. They can be tailored in width, height, materials, mounting configuration and optional windows to fit any automotive prep or sanding station layout.

Do the curtains include clear windows or vision strips?

Yes. Clear PVC or vision panels can be added so supervisors can monitor operations while the zone remains sealed from dust or spray.

Are these curtains retractable or movable?

Yes. Many systems use tracks, rollers or sliders, allowing the curtain to be moved aside for access, equipment movement or when the zone is inactive.

Can the curtains handle chemical cleaning and wash-downs?

Yes. The materials are formulated to stand up to high-pressure wash-downs, cleaning agents, water spray and solvents used in automotive finishing areas.

How easy is installation of wash-down curtains?

Yes. Most installations require basic hardware such as wall or ceiling mounts, tracks or grommets, and can be completed quickly without heavy construction.

Are these curtains waterproof?

Yes. The vinyl or PVC construction is waterproof, making it suitable for wet zones, rinse areas, and both horizontal and vertical spray exposure.

How do I clean and maintain these curtains?

Use mild soap and water, rinse off contaminants, and inspect the track and hardware regularly. Avoid harsh abrasives to maintain appearance and performance.

Are replacement panels available for these systems?

Yes. Individual panels, clear inserts or hardware components can be replaced without removing the entire curtain system, simplifying maintenance.

What is the expected lifespan of wash-down curtains in a body-shop environment?

With proper care and usage, they typically last several years. Actual duration depends on exposure to water, chemicals, abrasion and how well they’re maintained.

Do these curtains reduce cost compared to building a solid enclosure?

Yes. They cost significantly less than permanent walls, install faster, and can be reconfigured or removed if the facility layout changes or operations shift.

Can these curtains be used in areas with sanding, prepping and spray operations?

Yes. They’re equipped to separate sanding, wash, and preparation zones in automotive facilities, while containing dust, debris and spray for better workflow.

Will they help improve air quality in the workshop?

Yes. By isolating dust and overspray zones, ventilation and filtration systems can be focused and more efficient, improving shop air quality and worker comfort.

Are mounting options flexible for different ceiling heights?

Yes. Options include wall mounts, ceiling tracks, overhead sliders and freestanding frames, making them adaptable to tall bays or variable heights found in body shops.

Can the curtains be used in multi-station sanding or wash areas?

Yes. They can be configured into multi-panel systems with corner tracks or separate bays, enabling multiple prep or wash stations within a single shop area.

Are these curtains suitable for automotive refinishing beyond body shops?

Yes. They’re also used in marine, aircraft, industrial finishing and manufacturing facilities needing flexible, washable separations for sanding, wash down and spray zones.

Build Yours Online

Budget Price

Size: 20′w x 10′l x 10'h

Hanging Style: $2,800

Free-Standing Style: $4,800