OVERVIEW

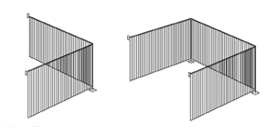

Welding booth strip curtains are used for welding booths where welders are lined up in individual booths or welding cells. These welding strips are often used at welding trade schools or for industrial manufacturing, where multiple welders are working in close proximity. They contain welding sparks, grinding sparks, blasting or any other harmful by products from welding.

The Industry Standard

Industrial And Educational Uses

Colleges And Trade Schools

Welding booth PVC strips are used in high schools, colleges, and trade schools all over the country. By using the AKON welding PVC strip curtains, these training facilities can provide a safe learning and work environment. Regardless of your needs, we can furnish and provide the correct weld strips to keep your students or staff safe.

Industrial and Manufacturing

Welding is a growing industry and AKON is the leader in providing safety weld strip curtains for major manufacturing facilities. Unlike trade-schools, manufacturing facilities have a demand for strip curtains of all shapes, sizes, and configurations to meet your demanding production needs.

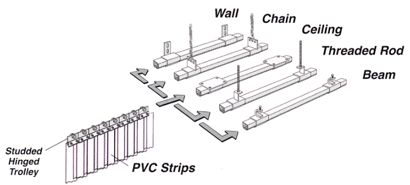

Hanging Welding Curtains

In addition to welding booth strip curtains, you can also utilize hanging welding curtains. These are used when complete access below the strips is required. These strips hang from above using threaded rod drops every 4' into the universal strip curtain hardware. This setup provides a low cost solution and complete access.

Welding Strip Colors

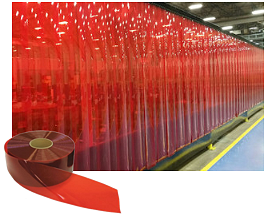

Tinted Red Bulk Roll

Darkness: 2 out 4

Cost: $$

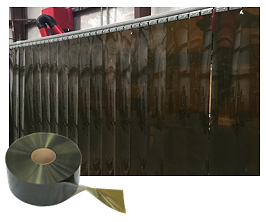

Tinted Bronze Bulk Roll

Darkness: 3 out 4

Cost: $$

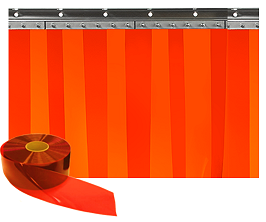

Tinted Orange Bulk Roll

Darkness: 2 out 4

Cost: $$$

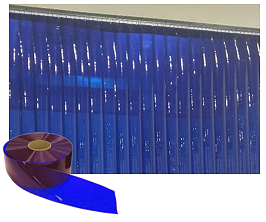

Tinted Blue Bulk Roll

Darkness: 2 out 4

Cost: $$

Tinted Green Bulk Roll

Darkness: 4 out 4

Cost: $$

Frequently Asked Questions

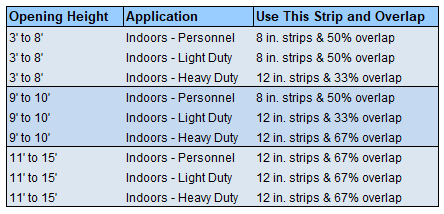

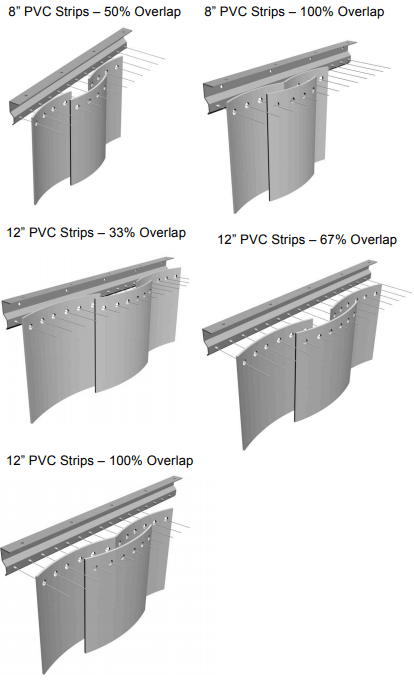

Strip curtain booths create safe work areas for welding by using flexible strips that hang in place while still allowing easy walk-through access. These booths help block sparks, reduce glare, and keep nearby workers protected without closing off the whole shop floor. The simple frame and strip system works in tight spaces and fits many layouts without heavy structural work. Shops set them up fast and move them when production changes. This FAQ explains how well the strips handle heat, how strong the frames are, and which layouts work best for different welding tasks.

Strip Curtain Booths – Frequently Asked Questions

What are strip curtain booths used for?

Strip curtain booths provide a flexible welding cell environment using overlapping PVC strips to separate zones, control access, and protect adjacent areas from sparks and welding arc flash.

What materials are strip curtain booths made from?

They use heavy-duty welding-grade PVC strips or flame-retardant vinyl mounted on brackets, rails or frames to resist spatter, UV flash and industrial usage in welding operations.

Are strip curtain booths flame-resistant?

Yes, chosen materials often meet flame-retardant standards designed for welding environments, reducing potential fire hazards from hot metal and spatter.

Do strip curtain booths block UV and arc flash?

Yes, when specified with tinted or welding-grade PVC strips, these booths reduce UV exposure and filter welding arc flash light improving safety in surrounding work areas.

Can strip curtain booths be customized to suit my facility?

Yes, widths, heights, strip thickness, color tints, mounting styles and door/opening configurations can be tailored to your workflow, space and safety requirements.

How are strip curtain booths installed?

Installation includes mounting a header track or support frame, hanging strips with specified overlap, and securing side/support hardware to ensure barrier effectiveness and smooth movement.

Do strip curtain booths include clear vision or walk-through sections?

Yes, clear or lightly tinted strips can be incorporated to allow visibility or pass-through access while still maintaining protective coverage in the booth area.

Can strip curtain booths be used outdoors or in semi-open bays?

Yes, if equipped with UV-stable PVC and weather-resistant hardware, they can be installed in covered or semi-open fabrication zones exposed to ambient conditions.

Do strip curtain booths help reduce noise?

They can help reduce sound transmission by acting as a physical partition, although their primary function is welding zone protection rather than full acoustic isolation.

Are replacement strips available for strip curtain booths?

Yes, individual PVC strips and mounting hardware can be replaced independently, helping to maintain performance without replacing the full system.

Do strip curtain booths support mobile or modular layouts?

Yes, modular strip systems or booth frames permit reconfiguration, relocation, or expansion to adapt as production needs or facility layout changes.

Are strip curtain booths compatible with fume extraction or ventilation systems?

Yes, they integrate with ventilation systems by defining the welding zone and helping direct airflow, making extraction more efficient and processing safer.

How long do strip curtain booths typically last?

With appropriate maintenance and usage, they can last several years. The exact lifespan depends on exposure to heat, abrasion, spatter and frequency of operational use.

Do strip curtain booths help with safety compliance?

Yes, they offer defined separation of welding operations, protection of adjacent areas and support compliance with welding-safety and partitioning requirements in industrial facilities.

What sizes are common for strip curtain booths?

Standard widths range from 8 ft to 20 ft+ and heights from 6 ft to 16 ft+; customization allows exact fit for your booth opening or fabrication cell layout.

Can strip curtain booths protect adjacent equipment and personnel?

Yes, by encasing the welding zone and limiting access, they help protect nearby machines, workflows and personnel from spatter, heat, sparks and welding arc flash.

Are strip curtain booths easy to maintain?

Yes, maintenance involves cleaning the strips, checking mounting integrity, inspecting strip overlap and replacing damaged strips when needed—generally minimal work.

Do strip curtain booths support layered barrier systems?

Yes, they can work alongside solid curtains, rigid panels or screens to create layered protection—strip curtains provide access and visibility while other layers add heavy-duty containment.

Are the mounting hardware and strips durable for industrial use?

Yes, these booths are built with industrial-grade mounting systems and welding-rated PVC strips engineered for abrasion, spatters, high-temperature exposure and repeated use.

What are the advantages of strip curtain booths over solid welding booths?

Strip curtain booths offer easier access, visibility, lower cost, modular layout flexibility, and simpler maintenance compared to solid curtain or rigid wall welding cells.

Photo Gallery

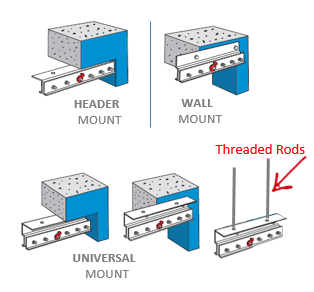

Static Mount

- Header Mount

- Wall Mount

- Universal Mount

- Threaded Rod Mount (Just a Feature of Universal Mount)

Free-Standing Mount

- Supported from the floor up

- Used in open floors when you can support from above

Rolling Hardware

- Allow the strips to roll out of the way

- Ideal for complete access when strips are not needed

- Note the strips roll like a barn door and do not fold up

Tube Mount

- Fits up to 2" diameter pipe

- Each pipe clamp is 4” wide and holds 2 strips (overlapped)