Choose A Style

Welding Booth Strips

For welding booths that require entry and exit for welders, we offer welding strip curtains for booths. No need to push to the side.

Replacement Welding Strips

Already have strip curtain hardware and just need new strips? You can purchase replacement strips here that mount to your existing hardware.

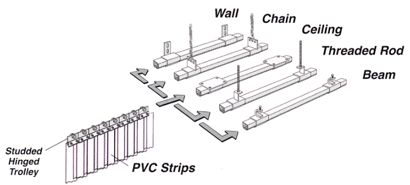

Hanging Welding Strip Curtains

Most commonly, it is hung with threaded rods that drop down from the ceiling. These welding curtain walls allow full access to materials.

Robot Weld Cell Strips

Robot welding cells often require material to move in quickly. The robot welding curtains allow rapid access to materials in and out.

Welding Strip Doors

Separating welding areas from non-welding areas requires welding strip doors. These doors reduce harmful UV rays.

Exhaust Hood Welding Strips

Exhaust hoods in welding areas help keep harmful fumes from welding operations contained. Funnels fume out the top.

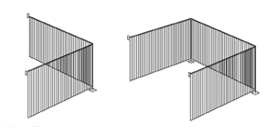

Free-Standing Welding Strips

Free-Standing welding strip curtains are used when the strips cannot be supported from above. Commonly used for Welding Booths.

Strips Come In Different Colors and Widths

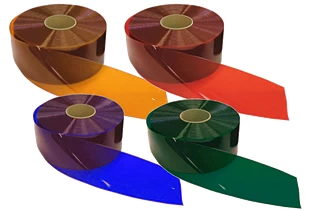

Weld Strip Colors

Welding strip colors vary based on customer preference. The amount of UV light blocked varies slightly from one color to another, but all colors reduce these harmful UV rays. The darker the shade, the more UV light that it will block. Please note that welding PVC strip curtains are not a substitute for welding helmets. They are made for indirect viewing of welding operations.

- Tinted Bronze Weld

- Tinted Red Weld

- Tinted Blue Weld

- Tinted Orange Weld

- Tinted Green Weld

- Opaque Black

- Opaque Blue

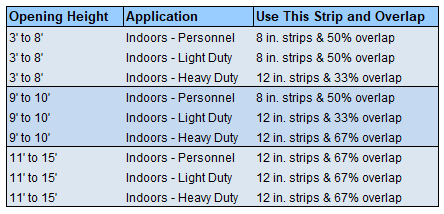

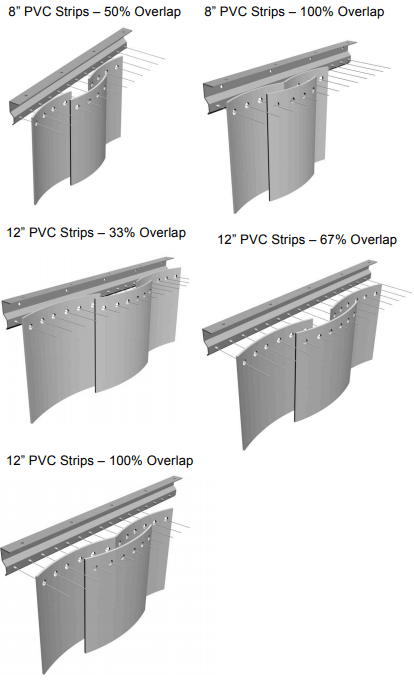

PVC Strip Widths

Strips come in several different widths and thicknesses depending on the height of your opening and the type of traffic that will pass through it. Strip thickness is an important part of picking a strip for your PVC strip door so that entry and exit is quick and easy. The two most common sizes are shown below.

- 8" width x .080" thick (Most Common)

- 12" width x .120" thick

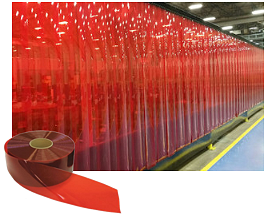

Welding Strip Colors

Tinted Red Bulk Roll

Darkness: 2 out 4

Cost: $$

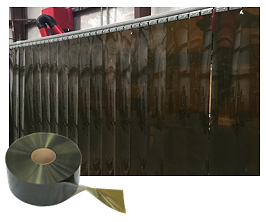

Tinted Bronze Bulk Roll

Darkness: 3 out 4

Cost: $$

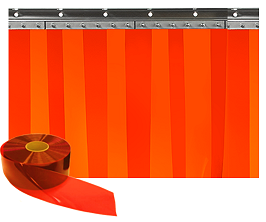

Tinted Orange Bulk Roll

Darkness: 2 out 4

Cost: $$$

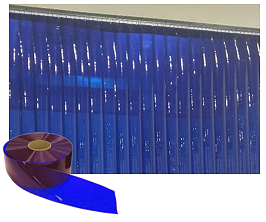

Tinted Blue Bulk Roll

Darkness: 2 out 4

Cost: $$

Tinted Green Bulk Roll

Darkness: 4 out 4

Cost: $$

Frequently Asked Questions

Welding strip curtains let workers and materials pass through welding areas constantly without stopping to push solid curtains aside or open doors. The overlapping strips hang vertically and part when people walk through, then fall back into place automatically to keep blocking UV light and sparks. Robot welding cells use these because automated equipment needs quick material access without anyone manually operating barriers. Different tint colors block varying amounts of UV radiation, with darker shades offering more protection for closer viewing distances. This FAQ covers more about welding strip curtains and talks about which strip width works for different work areas and how long strips last before needing replacement in high traffic welding booths.

Welding Strip Curtains – Frequently Asked Questions

What are welding strip curtains used for?

Welding strip curtains are used to separate welding zones, protect adjacent work areas from arc flash, UV radiation, welding sparks and slatter, while allowing visibility and workflow movement.

What materials are welding strip curtains made from?

They are typically made from welding-grade PVC or heavy-duty vinyl strips with UV-stable coloration, fire-retardant features and abrasion resistance suitable for welding bay environments.

Are welding strip curtains flame-resistant?

Yes, welding strip curtains often meet fire-retardant standards and are designed for industrial welding applications to mitigate fire risk from sparks and hot metal.

Do welding strip curtains block UV and arc flash?

Yes, welding strip curtains filter harmful UV rays and welding arc flash light when using tinted or welding-grade PVC, improving safety for workers in adjacent areas.

Can welding strip curtains be customized for our facility?

Yes, they can be customized in strip width, length, color tinting, overlap amount, mounting system and overall width/height to fit your welding zone layout.

How are welding strip curtains installed?

Installation uses mounting brackets or clips over a header bar, or a sliding track system; correct overlap and width are essential for effective welding protection.

Are clear vision panels available in welding strip curtains?

Yes, some models include clear or lightly tinted strips for vision and light transmission while maintaining protective welding-grade strips around them.

Can welding strip curtains be used outdoors?

Yes, when specified with UV-resistant strips and durable hardware they can be used in covered or semi-outdoor fabrication areas that include welding operations.

Do welding strip curtains help reduce noise?

They contribute to noise reduction by helping isolate welding areas from other workspaces, although their primary function is welding protection rather than acoustic performance.

Are replacement strips available?

Yes, individual strips or mounts can be replaced when damaged without replacing the full curtain system, helping keep maintenance cost down.

Do welding strip curtains support mobile or modular layouts?

Yes, modular strip systems or sliding strip setups allow sections to move or slide open for access while maintaining protection when closed.

Are welding strip curtains compatible with ventilation or fume extraction?

Yes, they can work alongside ventilation and fume-extraction systems by defining welding zones and keeping processes contained near the source of welding.

How long do welding strip curtains last?

With proper maintenance—they typically last several years depending on exposure, environment, strip material and traffic in the welding area.

Do welding strip curtains help with safety compliance?

Yes, they support compliance with welding safety standards (such as ANSI/AWS, ISO 25980) by creating distinct welding zones and protecting adjacent workers and equipment.

How much maintenance is required?

Maintenance is minimal: inspect strip condition, check overlap and mounting alignment, clean debris and replace worn strips to maintain performance.

What are the typical sizes for welding strip curtains?

Widths can range from a few feet to 20 ft or more; strip widths commonly 200–400 mm with custom height options to fit your welding bay or fabrication opening.

Do welding strip curtains protect adjacent equipment and personnel?

Yes, by physically partitioning the welding zone they protect nearby machines, tooling, on-going work and personnel from heat, sparks, spatter and UV exposure.

Can welding strip curtains be used in conjunction with other barriers?

Yes, they often work alongside welding curtains, screens, fixed partitions or walls to create layered protection in high-hazard welding environments.

Are the mounting hardware and strips durable?

Yes, welding strip curtains are built with heavy-duty mounting systems and strips rated for abrasion, heat, and rugged industrial use in welding zones.

What are the advantages of welding strip curtains over full welding curtains?

Strip curtains offer visibility, modular flexibility, lower cost, easier maintenance and quicker replacement compared to full fabric or vinyl welding curtains.

Do welding strip curtains meet industrial welding-grade requirements?

Yes, when specified correctly (welding-grade PVC, correct overlap, UV and fire ratings) they meet requirements for welding bay protection and worker safety.

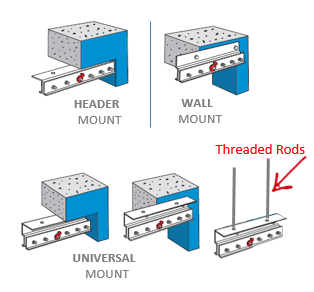

Static Mount

- Header Mount

- Wall Mount

- Universal Mount

- Threaded Rod Mount (Just a Feature of Universal Mount)

Free-Standing Mount

- Supported from the floor up

- Used in open floors when you can support from above

Rolling Hardware

- Allow the strips to roll out of the way

- Ideal for complete access when strips are not needed

- Note the strips roll like a barn door and do not fold up

Tube Mount

- Fits up to 2" diameter pipe

- Each pipe clamp is 4” wide and holds 2 strips (overlapped)