OVERVIEW

Manufactured in a standard 48” width. The sound panels have bound hems, brass grommets 12” O.C. along the top and double grommets 18” O.C. along side edges for fastening to adjacent panels. These can be used for small dividers or for dividing an entire facility. The panels are modular and can be detached and used in other areas or stored when not needed. Can also be used outdoors when panels are treated. We apply a silicone to the panels to weatherize them.

Sound Barrier Examples

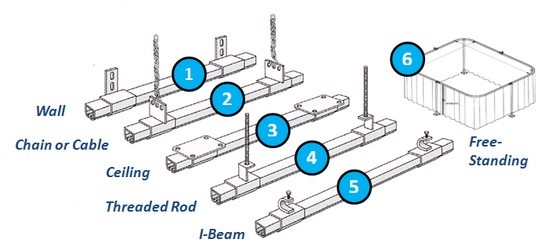

Mounting Options

Rolling Track Mounts

The panels can be hung using steel tracks with roller hooks. This allows the panels to be rolled out of the way when not needed. This allows for material flow into and out of work areas. Even if the panels do not need to roll, this method is a very efficient and gives the installation a very clean look.

Note, the panels do not accordion fold so if you need to roll them out of the way you will need double the track as you do panel width. For example if you have 10′ of sound panels then you would use 20′ of total track to move them completely out of the way. You can utilize our radius corners to move them around the corner.

Static Mounts

Aluminum angle which comes in 8′ sticks, can be used to hang the panels in a static position. I-beam clamps are also common when attaching directly to beams, purlins, and joists. The edge clamp has a set screw to attach the flange and the eye-bolt goes through the grommets at the top of the panels.

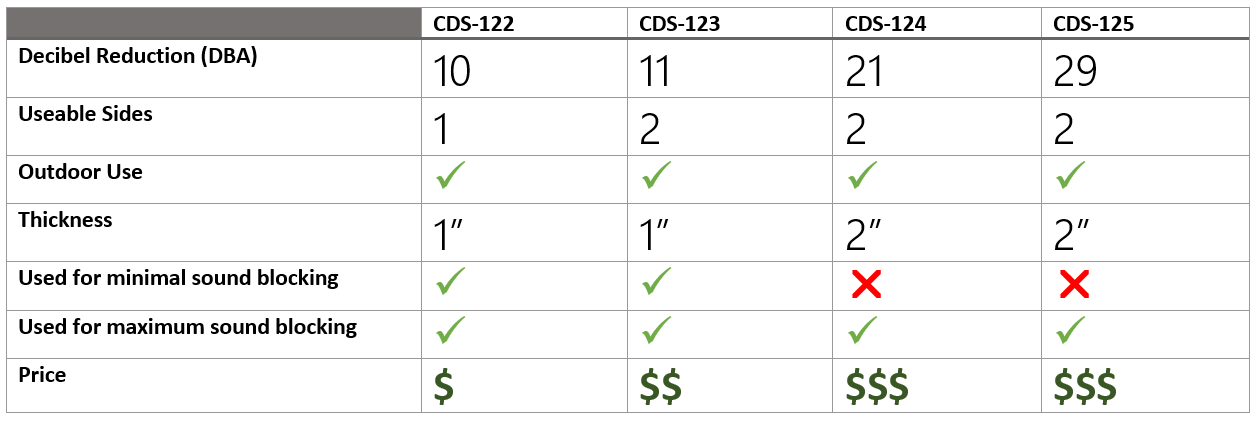

Choose the Right Sound Panel

Sound Panel Types

Common features

- Color: Grey or white

- Material: Fiberglass batting with vinyl coated fiberglass skin

- Grommets: 12″ center at top, 18″ centers on sides

- Standard Sizes: 4′, 6′,8 ‘, 10’ – Custom sizes also available

- Resistant To: Oils, Grease and Mildew

- Fire Rating: Meets Federal MVSS #302 flame-retardant tests, ASTM E84 Class I

Model: CDS-122

Useable Side: One Side

Thickness: 1″

Bound Edges: Edges are not sewn shut

Roll size: 4’w x 50’l – (covers 200 sq/ft) @ 50lbs per roll

DBA Reduction: Estimated up to 10 DBA

Note: Moderate sound absorber. Ideal for onsite field cutting. These panels cannot be hung in the middle of a room. This material can only be used flat against a surface; walls, machinery, etc. Can be used to supplement other Noise Control Products. Consider using ceiling baffles & acoustic screens in the same area.

Spec Sheet: View PDF Spec Sheet

Price: $

Model: CDS-123

Useable Side: Both Sides

Thickness: 1″

Bound Edges: Edges are not sewn shut

DBA Reduction: Estimated up to 11 DBA

Note: Used for minimal sound reduction. Ideal for onsite field cutting. Same as the CDS-122 above but with 2 usable sides. The Vinyl skin is on both sides which allows it to be hung in the middle of the room.

Spec Sheet: View PDF Spec Sheet

Price: $

Model: CDS-124

Useable Side: Both Sides

Thickness: 2″

Bound Edges: Edges are sewn shut

DBA Reduction: Estimated up to 21 DBA

Note: An ideal sound absorber. Two layers of 1” thick, 2 lb./cu. ft. density fiberglass batting, quilted between 2 layers of vinyl coated fiberglass facing.

Spec Sheet: View PDF Spec Sheet

Price: $

Model: CDS-125

Useable Side: Both Sides

Thickness: 2″

Bound Edges: Edges are sewn shut

DBA Reduction: Estimated up to 29 DBA

Note: An ideal sound absorber and barrier. Best in extremely noisy areas. Same as the CDS-124 but with an added 1 lb./sq. ft. mass loaded vinyl barrier sheet added in the middle. That makes this curtain an ideal sound absorber and blocker.

Spec Sheet: View PDF Spec Sheet

Price: $

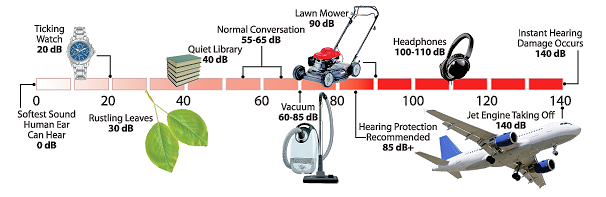

Decible Ratings