Construction Noise Control

Benefits for Construction Companies

- Improved Community Relations – lessens neighbor noise concerns, so preserving a good business image.

- Faster Project Approvals – helps to allay environmental noise issues, so facilitating quicker permission approval.

- OSHA and Local Compliance – supports occupational safety standards and noise control rules.

- Increased Worker Focus – makes the surroundings quieter and more under control for on-site workers.

- Reusable and Portable – Moving, setting up, and reusing panels over several job sites is simple.

- Reduced Risk of Fines or Shutdowns – Shows proactive noise reduction, therefore reducing the possibility of enforcement proceedings.

Benefits for Nearby Residents

- Less Daily Disruption – greatly reduces construction noise that would otherwise interfere with daily life.

- Improved Sleep and Comfort – Affects sleep particularly in early morning or during nighttime work.

- Better Air Quality – Many panels also serve as dust filters, therefore enhancing the quality of the surroundings.

- Preserved Property Value – Quiet settings help to preserve the attractiveness and worth of surrounding houses.

- Enhanced Safety Perception – As physical and visible buffers, barriers help residents feel more safe.

Style 1 - Quilted Construction Sound Panels

Quilted Thick Construction Sound Panels are designed to control noise on ongoing construction sites. These thick panels, sewn with UV-resistant thread and built with two layers of 1-inch thick or 2-inch thick acoustical fiberglass batting, are covered in durable, weatherproof polyester facing for long-term outdoor durability. They efficiently capture and block heavy machinery, jackhammers, and generator construction sounds. Easily installed to fences, scaffolding, or temporary enclosures, the panels produce quieter job areas supporting worker safety and less disturbance to surrounding neighbors. Standard 4' x 8' widths or custom lengths up to 25 feet; several colors for branding or visibility.

Style 2 - Mass Loaded Panels

Designed to elegantly, professionally block construction noise using a high-density, non-quilted material, AKON's Mass Loaded Vinyl (MLV) sound barrier is Unlike quilted fiberglass panels that absorb noise, this smooth vinyl material concentrates on stopping sound transmission. In cases when controlling noise bleed through takes precedence over absorbing echo or reverberation, it is perfect. Made of reinforced polyester and sturdy PVC, this material is quite resistant to UV, weather, and tearing. With a 25 STC rating, it works well to lower noise from generators, compressors, demolition activity, and loud machinery. Grommets along the perimeter make hanging fences, scaffolds, or temporary obstacles around loud areas simple.

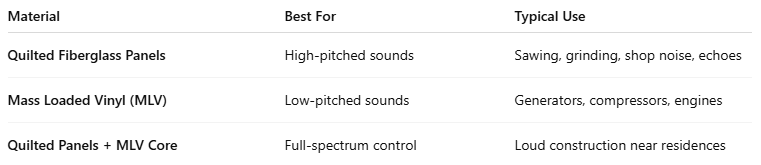

Which Material Is Right For You?

Mass Loaded Vinyl

Pros

- Excellent sound blocking – Great for keeping noise from escaping construction sites

- Highly durable – Handles tough outdoor conditions, including rain, UV, and dust

- Easy to clean – Smooth PVC surface wipes down quickly on dirty jobsites

Cons

- It does not absorb sound; it reflects sound waves, which can increase echo inside enclosed areas.

When to Choose This Material

- The primary concern is preventing noise from escaping a jobsite into surrounding neighborhoods.

Quilted Sound Panels

Pros

- High sound absorption – Reduces echo and reverberation near equipment

- Good sound blocking – Helps reduce transmission while absorbing energy

- Worker Protection - Effective for worker protection from loud equipment (jackhammers, compressors, etc.)

Cons

- Bulkier and thicker (2") – May require more secure mounting in windy or open areas

- Slightly harder to clean – Quilted surface may retain dust more than smooth vinyl

When to Choose This Material

- The focus is on reducing noise at the source, especially for worker protection.

- You need to reduce echo and reverberation around machinery, compressors, or jackhammers.

- Creating semi-enclosed zones or equipment wraps for OSHA compliance or worker comfort.

- Some absorption is needed indoors or inside modular enclosures.

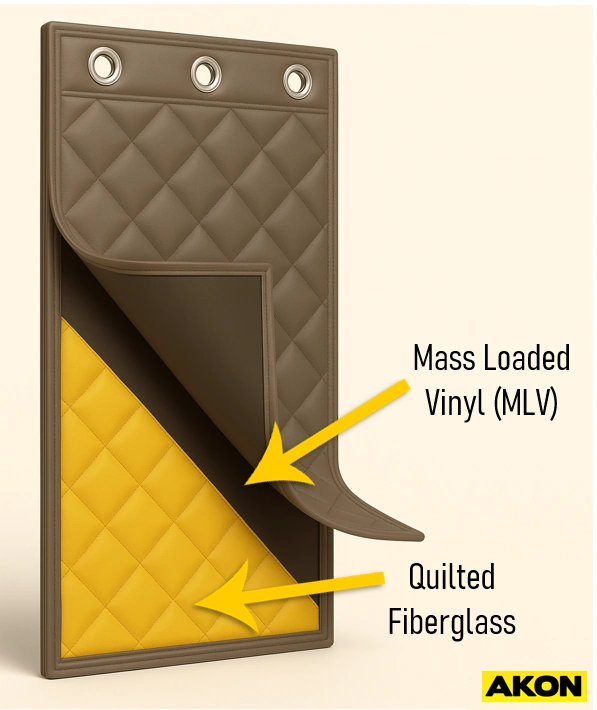

(NEW) A Hybrid Solution

Ideal for projects requiring both worker protection and neighborhood noise compliance. AKON’s hybrid sound panels combine high-performance sound blocking and sound absorption in a single product. These panels feature two layers of dense 1" or 2" thick fiberglass batting, combined with a 1 lb/ft² mass loaded vinyl core, all quilted together between heavy-duty, weather-resistant vinyl-coated facings. The result is an ultra-effective barrier that reduces noise transmission (STC 29) while also absorbing on-site noise (NRC 0.65).

Construction Sound Barrier Walls

Designed to cut noise on difficult sites, AKON Construction Site Barrier Walls are designed from robust quilted panels. These panels resist extreme outdoor conditions and efficiently absorb sound. An optional Mass Loaded Vinyl (MLV) core is offered to restrict even more noise from leaving the site, hence improving performance. Perfect for around building zones, generators, jackhammers, or other loud equipment, modular and easy-to-install With AKON's tough and dependable jobsite sound barrier walls, improve site safety, comply with noise rules, and keep friendly neighbors.

AKON Mass Loaded Vinyl (MLV) is a high-performance sound barrier MLV can be readily zip-tied to chain-link fence or temporary structures, either in tiny, controllable parts or in big rolls for erecting full-scale barrier walls. Its flexible, thick construction blocks noise, allowing builders to comply with local noise regulations and minimize disturbance. MLV is strong and weather-resistant ideal for outdoor use around loud operations, demolition areas, and heavy equipment. The MLV from AKON provides easy, flexible professional-grade noise suppression.

Portable Construction Sound Blocking

Modular Sound Blocking Screens provide industrial zones and building sites portable, high-performance noise control. Perfect for generator or jackhammer activities, every 4′ x 8′ 4′ screen has mass-loaded vinyl and quilted fiberglass to cut noise by up to 29 dBA. Easy setup and mobility of the steel frame with snap-button assembly guarantees Easy extension to cover loud equipment or work areas is made possible by velcro edges and Add-A-Panel closures. These durable, flame-resistant, weather-tolerant screens satisfy OSHA noise safety requirements and help guard workers' hearing.

Use AKON Portable Sound Blocking Panels for efficient outdoor noise reduction around building equipment including compressors, generators, and jackhammers. Made especially for outdoor settings, these modular, transportable barriers block and absorb loud equipment sounds by combining durable, weather-resistant vinyl with a dense, 1" thick quilted fiberglass core. On job sites, their strong, quick-connect frames let you quickly set and move easily. Instantaneously create flexible, semi-enclosed noise control barriers to shield adjacent communities and workers from disturbing mechanical sounds. For outdoor building sites, AKON sound panels provide dependability, adaptability, and longevity.

Construction Soundproofing Enclosures

For best noise suppression, completely surround loud machinery using specially designed, padded industrial sound panels. Four walls and an optional ceiling in these enclosures help to produce a total sound barrier. Made to meet your precise measurements, they significantly lower noise levels, enhance worker safety, and preserve accessibility by hinged or detachable panels. Perfect for factories, offices, and any setting where machinery noise has to be controlled.

Establish a peaceful haven using our specially made sound enclosures for individuals. With its four padded walls and roof, these buildings block outside noise and provide quiet areas in noisy surroundings. Perfect for offices, warehouses, or workshops when concentrated labor, meetings, or breaks call for solitude from nearby noise sources.

Quilted - Single Sided

Model: CDS-Quilted-Single

Usable Sides: One Side

Thickness: 1″

Bound Edges: Yes

Grommets: Yes - On perimeter

Panel Sizes: 4’W x 4’H | 4’W x 6’H | 4’W x 8’H | 4’W x 10’H and custom sizes

Price: $

Overview: Designed for use against flat surfaces, including walls or the sides of solid fencing, AKON's Single-Faced Quilted Fiberglass Panels feature Quilted Fiberglass Material (QFM) on one side and are specifically designed for use on construction sites. Lightweight and semi-flexible, QFM delivers a balance of sound absorption and noise-blocking performance. These panels are ideal for hanging on temporary fencing, scaffolding, or structural framing to reduce construction noise. Commonly paired with plywood walls or used alone, they help control reflected sound and minimize noise pollution around active job sites, improving compliance and community satisfaction.

Quilted - Double Sided

Model: CDS-Quilted-Double

Usable Sides: Both

Thickness: 1″ and 2"

Bound Edges: Yes

Grommets: Yes - On perimeter

Panel Sizes: 4’W x 4’H | 4’W x 6’H | 4’W x 8’H | 4’W x 10’H and custom sizes

Price: $

Overview: Double-faced quilted fiberglass panels are ideal for hanging applications and chain-link fences. These applications are suitable for situations where both sides of the material will be exposed to the weather. For example, mounting onto chain-link fencing, scaffolding, or top-down supported systems where the panel hangs from above. These panels also offer superior sound suppression on job sites because both sides are engineered to absorb noise. Whether used to surround loud equipment or create temporary sound enclosures, they help reduce noise pollution and improve compliance with local construction noise regulations.

Quilted - Double Sided With Mass Loaded Vinyl

Model: CDS-Quilted-Double

Usable Sides: Both

Thickness: 2"

Bound Edges: Yes

Grommets: Yes - On perimeter

Panel Sizes: 4’W x 4’H | 4’W x 6’H | 4’W x 8’H | 4’W x 10’H and custom sizes

Price: $$

Overview: Quilted Fiberglass Panels with Internal Mass Loaded Vinyl (MLV) offer a powerful combination of sound absorption and sound blocking—ideal for high-noise construction sites. These hybrid panels feature a dense MLV core sandwiched between layers of quilted fiberglass, delivering both noise reduction and sound containment in one solution. Designed for hanging on fencing, framing, or curtain tracks, they are perfect for surrounding loud equipment or creating temporary enclosures. The quilted fiberglass absorbs echo and reverberation, while the internal MLV blocks sound from passing through—making these panels a top choice for job sites where both internal and external noise control is critical.

Vinly - Mass Loaded

Model: CDS-Mass-Loaded-Vinyl

Usable Sides: Both

Thickness: 1/4"

Grommets: Optional

Roll Sizes: 54" and 96" wide | custom sizes available

Price: $

Overview: Mass Loaded Vinyl (MLV) is a high-density noise barrier designed to block sound transmission in demanding construction environments. Ideal for hanging on fences, walls, or framing, MLV is a flexible yet durable material that adds mass to any surface, effectively reducing sound penetration. Unlike porous materials that absorb sound, MLV reflects and blocks noise—making it a perfect solution for job sites requiring maximum noise control. Often used behind or between other materials like quilted fiberglass, MLV is essential when meeting construction site noise ordinances and minimizing disruption to surrounding areas.