Used For Welding and Ovens

Exhaust Hood Welding Strips

Exhaust hoods in welding areas help keep harmful fumes from welding operations contained and funneled to the top and away from workers.

Oven Exhaust Hood Curtains

Most commonly used in restaurants for pizza ovens and but also in a variety of other baking ovens. The strips direct the heat away from the workers.

Contain Fumes and Odors

Made To Order For All Hoods

Strips Come In Different Colors and Widths

Weld Strip Colors

Welding strip colors vary based on customer preference. The amount of UV light blocked varies slightly from one color to another but all help reduce harmful UV rays. The darker the shade, the more UV light that it will block. Please remember, welding pvc strip curtains are not a substitute for welding helmets. They are made for indirect viewing of welding operations.

- Tinted Bronze Weld

- Tinted Aztec Red Weld

- Tinted Blue Weld

- Tinted Orange Weld

- Tinted Bronze

- Opaque Black

- Opaque Blue

- Opaque Green

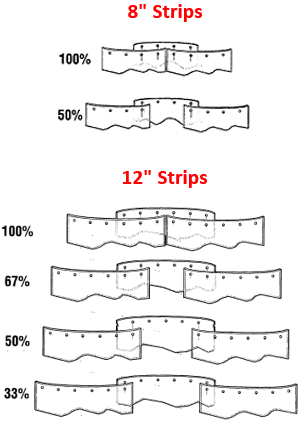

PVC Strip Widths

Strips come in several different widths and thicknesses depending on the height of your opening and the type of traffic that will pass through it. The strip thickness is an important part of picking a strip for your PVC strip door so that entry and exit is quick and easy. The two most common sizes are below.

- 8" width x .080" thick (Most Common)

- 12" width x .120" thick

Frequently Asked Questions

Exhaust hoods pull fumes and heat upward but only work well when the opening stays enclosed enough to direct airflow correctly. Open hoods let contaminated air escape sideways into work areas instead of getting captured and vented out. Strip curtains around hood openings funnel fumes upward while workers still reach in for welding or oven access without fighting doors. Welding shops contain harmful fumes and UV light this way, and restaurant kitchens direct pizza oven heat away from cooks. This FAQ covers which strip materials handle high heat without melting, whether these actually improve exhaust efficiency, how strip width changes performance, and if constant pushing through strips during busy shifts becomes annoying enough to cause complaints.

Exhaust Hood Strip Curtains – Frequently Asked Questions

What are exhaust hood strip curtains used for?

Exhaust hood strip curtains are used to help contain cooking vapors, grease particulate, smoke and airborne emissions around commercial exhaust hoods, improving kitchen airflow and separation of zones.

What materials are used in exhaust hood strip curtains?

They’re commonly made from flame-retardant PVC, vinyl or specialized fire-rated materials designed to resist cooking heat, grease deposits, smoke and frequent cleaning in commercial kitchens.

Are these curtains flame-resistant?

Yes, exhaust hood strip curtains use fire-rated materials and mounting systems compliant with commercial kitchen code to resist ignition, heat and grease exposure around cooking equipment.

Do these strip curtains filter smoke or odors?

They don’t filter smoke or odors themselves, but they help contain and direct them into the exhaust hood by acting as a barrier, improving ventilation efficiency and kitchen air quality.

Can exhaust hood strip curtains be customized?

Yes, you can specify the width, height, material type, strip thickness, overlap percentage and even transparent sections to match your exhaust hood layout and traffic flow.

How are exhaust hood strip curtains installed?

Installation includes mounting a header or rail near the hood opening, hanging strips with proper overlap, and ensuring clearance for equipment and fork-lift access, plus compliance with grease-fire laws.

Do these curtains help with airflow control?

Yes, they help channel airflow by restricting uncontrolled drafts around the hood area, improving capture of cooking vapors and enhancing ventilation system performance.

Can the curtains be used in outdoor kitchen/hood setups?

Yes, provided you use UV-stable, weather-resistant strip materials and corrosion‐resistant hardware — suitable for semi-outdoor cooking or exhaust areas.

Are replacement strips available for these curtains?

Yes — individual strips, mounting rails and brackets can be replaced enabling maintenance without replacing the full curtain system.

Do exhaust hood strip curtains help with grease containment?

They help reduce the spread of grease particulates into adjacent spaces by providing a physical barrier, simplifying cleanup and reducing cross-contamination between zones.

Are vision or clear strip options available?

Yes — clear or lightly tinted strip options are available to maintain visibility and light transmission while still providing a grease and smoke barrier.

Can these curtains be cleaned easily?

Yes — the materials are designed for frequent wipe-down or wash-down operations, and replacement of worn strips is typically fast and easy.

Do they meet commercial kitchen safety standards?

Yes — when properly selected and installed, they assist compliance with local building, fire and health code requirements for commercial kitchens and cooking operations.

How long do these strip curtains last?

With proper use and cleaning, exhaust hood strip curtains typically last several years, though life depends on exposure to heat, grease, traffic and maintenance habits.

Can they integrate with existing kitchen partitions?

Yes — they can complement kitchen partitions, fire curtains or mobile wall systems to create flexible zones around cooking equipment and hoods.

Do these curtains help with noise control?

They provide minimal acoustic benefits but help reduce drafts and airflow noise around the hood opening, contributing to a more stable air environment.

What sizes are typical for exhaust hood strip curtains?

Typical widths range from 6 ft to 20 ft or more, heights from 6 ft to 12 ft, and custom sizing is available to match hood opening dimensions.

Are these suitable for high traffic areas?

Yes — they are designed to handle frequent passage of equipment, personnel and carts while still maintaining zone separation and air-flow control.

What are the advantages of these strip curtains over solid panels?

They allow easier access for carts and equipment, better visibility, simpler maintenance and lower cost while still providing a barrier to grease, smoke and airflow.

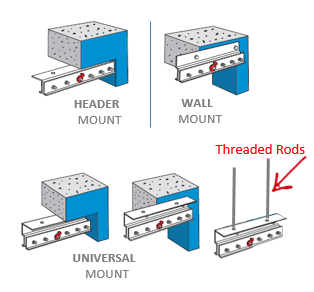

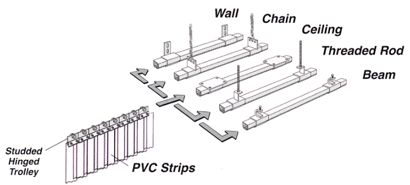

Static Mount

- Header Mount

- Wall Mount (Most Common)

- Universal Mount

- Threaded Rod Mount (Just a Feature of Universal Mount)

Free-Standing Mount

- Supported from the floor up

- Used in open floors when you can't support from the exhaust hood.

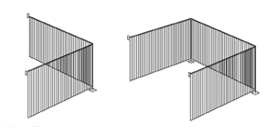

Rolling Hardware

- Allow the strips to roll out of the way

- Ideal for complete access when strips are not needed

- Note the strips roll like a barn door and do not fold up

Tube Mount

- Fits up to 2" diameter pipe

- Each pipe clamp is 4” wide and holds 2 strips (overlapped)