OVERVIEW

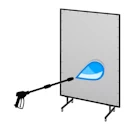

Maximize your floor space and contain paint and water spray with AKON paint spray booth curtains. The auto body curtains are the ideal solution for prep stations and industrial customers all around the country. Once installed, the curtains create work stations or work stalls that will contain sparks, paint, water over-spray, aluminum dust, steel dust and most chemical sprays.

Create Work Zones In Your Shop

Quick To Deploy And Store

The Leader In Spray Booth Curtains

Made to Order Painting Curtains

Ideal Applications

- Paint Prep Stations - Create a clean zone for masking and prep work before spraying.

- Retractable Paint Booths - Easy to open and close so you can get in and out, and they keep paint overspray inside while they are in use.

- Detailing / Wash Bays - Stop water and cleaning products from spreading into other parts of the shop.

- Undercoating Bays - Capture mess from rust-proofing and underbody sprays so it doesn’t reach nearby work areas.

- Undercoating Bays - Keep drips and overspray from rust-proofing and work on the underbody from getting out.

- Grinding and Sanding Bays - Keep dust from spreading and keep nearby vehicles and tools safe.

- Undercoating Curtains - extra layer of protection where you need them for heavy coatings or messy work.

Why They Work Better

- Lower Cost - Curtains cost much less than building permanent walls with drywall or panels.

- Flexible Work Areas - Divide the shop into sections so that painting, sanding, and other tasks can all happen at the same time without getting in each other's way.

- Cleaner Air - Keeps dust, overspray, and fumes inside the booth area, which makes the shop a safer and more comfortable place to work.

- Easy to move around - since the curtains are retractable, you can easily get in the production area and it is easy to close as well as needed.

- Meets Safety Standards- Materials are fire-rated and meet required safety regulations.

- Quick Installation - They are easy to install and won't disrupt your production for the whole day just to get it set up. It can also be moved around to fit the needs of our work area.

Built to Last

Here’s what makes these curtains hold up in busy shop conditions:

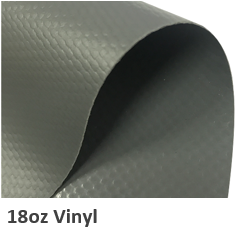

- Made with tough 18 oz coated vinyl that stands up to daily shop use.

- Uses 16-gauge galvanized steel hardware, so it won’t rust out quickly.

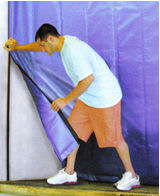

- Curtains slide open and shut easily on rolling hooks.

- Edges are reinforced with extra stitching so they don’t wear out as fast.

- A polyester scrim layer inside the vinyl adds strength and helps stop tearing.

Designed For Speed and Flexibility

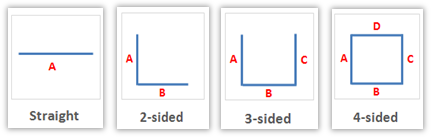

Common Layouts

Paint booth curtains, as well as curtains for other applications, can be set up in different layouts. They may be single-sided, double-sided, three-sided, or built as a full four-sided enclosure. Just let AKON know the style you need, and we will build it to match your exact specifications.

Optional Components

- Floor anchors to secure the painting divider curtain to the floor

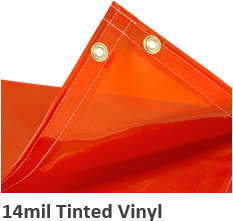

- Many custom colors to choose from to match your facility

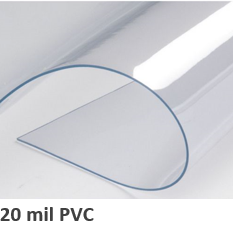

- Clear vision panels allow line of sight through curtains

- Chain weight pocket ensures curtain will not blow around

Installation

Setting up the paint booth curtain tracks is fast and straightforward. When your curtains arrive, just unbox them and follow the included instructions. The track hardware connects together in a modular design, and the roller hooks slide in easily. Once the track is mounted, simply attach the curtains using the grommets along the top. It’s a quick and hassle-free process.

Maintaining The Curtains

The paint spray curtains are made from a slick vinyl material similar to a shower curtain. They are easy to maintain, just wipe them clean when dusty or wash them down if they get dirty. For tougher stains, a mild cleaning agent can be used. The material is mildew-resistant and holds up well against most chemicals. If a tear occurs, clear patch tape is available for quick repairs.

Aluminum Dust

Aluminum dust is now part of new car frames and dealing with that dust is now a critical consideration for auto-body shops. The processing of these aluminum body cars and trucks requires a completely sealed off area. Our aluminum repair enclosure curtains will divide these work areas where grinding is taking place from the rest of the shop.

Filter Panels

The AKON body shop curtains can also feature filter panels in sizes of 4′ x 4′ or 4′ x 2′ to allow for negative pressure generated inside of the curtain enclosure due to ventilation systems. These replaceable paint filters Velcro onto the curtain and can be replaced if they become too clogged to function.

Frequently Asked Questions

Paint and spray booth curtains create a clean, safe, and flexible work area for controlling overspray in auto body shops, woodworking, and industrial finishing. They are an affordable alternative to rigid spray booths and can be customized to fit almost any space. The questions below explain how these curtains work, what options are available, and how to install and maintain them for long-lasting use.

What are paint and spray booth curtains?

They’re flexible vinyl barriers that create a defined spray area without building permanent walls. The curtains help contain overspray, reduce cleanup, and protect nearby tools and vehicles. Mounted on track or frames, they slide open for access, then close to form a workspace that supports safe, repeatable finishing processes.

What materials are used for spray booth curtains?

Most systems use industrial PVC or specialty vinyls. Solid upper and lower panels provide strength, while clear center windows maintain visibility. You can specify fire-retardant, anti-static, or reinforced materials for demanding shops. Seams are heat-welded, and hems are finished for durability under routine wash-downs and chemical exposure.

Do these curtains resist paint overspray and common solvents?

Yes. The slick vinyl surface sheds overspray and wipes clean with compatible solvents. For stronger reducers or cleaners, choose upgraded chemical-resistant compounds. Always test on a small area first, confirm MSDS guidance, and avoid abrasive pads that can scratch clear vision panels or cloud the surface.

Can I customize size, layout, and window placement?

Yes, most paint booth curtains are built to order. Provide width, height, and layout (straight, L-shape, U-shape, or full enclosure). Options include clear vision zones, colored borders, floor sweeps, overlap seams, and zippered or hook-and-loop access points. Custom track kits match your ceiling structure and workflow.

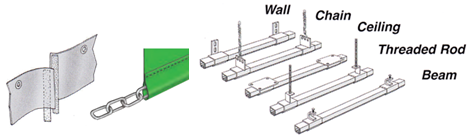

What mounting and track options are available?

Common choices include ceiling-hung roller-trolley track for smooth sliding, wall-mount brackets for perimeter runs, and free-standing frames when structure is limited. Hardware is typically corrosion-resistant for wash-down areas. Choose based on ceiling height, sprinkler clearance, and whether you need to park panels out of the way.

How do curtains compare to rigid spray booths?

Curtains cost less, install faster, and reconfigure easily as jobs change. Rigid booths offer higher containment and integrated airflow control but require more space, permits, and capital. Many shops use curtain enclosures for prep, priming, or light production, reserving rigid booths for high-volume or code-critical finishing.

Will paint booth curtains affect ventilation or airflow?

They slightly alter airflow by creating a localized zone. Curtains work best alongside an exhaust or downdraft system that maintains negative pressure. Coordinate with your facilities or EHS team to confirm capture velocity, make-up air, and any gaps or floor sweeps needed for steady, predictable ventilation.

Can I add filter panels for negative pressure?

Yes. Replaceable filter panels (commonly 4′×4′ or 4′×2′) allow air to enter while exhaust pulls contaminants out, helping maintain negative pressure. Filters attach with Velcro for quick swaps when they load up. Select media compatible with your coatings and change them on a routine maintenance schedule.

Are fire-retardant or anti-static (ESD) options available?

Yes. Many vinyls are available with FR ratings (e.g., NFPA 701) and anti-static properties to help manage ignition sources and dust attraction. Request documentation with your quote, and ensure the selected compound complements your coatings, grounding practices, and local fire safety requirements.

Do these curtains meet OSHA or local codes?

Curtains support best practices for overspray control, but compliance depends on your ventilation, electrical, and fire protection strategy. Consult your authority having jurisdiction and safety officer. We can supply material specs, FR data, and layouts so your team can verify code alignment for the installation.

How do I seal the booth at the floor and ceiling?

Use weighted hems and floor sweeps to limit drafts and overspray escape. At the ceiling, mount track near structure and overlap panels at corners. Where tighter control is needed, add magnetic or Velcro side seals and threshold strips to improve containment while keeping access convenient.

Are these curtains suitable for automotive, woodworking, or industrial use?

Yes. Paint and spray booth curtains are used in auto body shops, furniture finishing, metal fabrication, and general manufacturing. Choose the compound and options that match your coatings, airflow, and cleanup routine. Clear windows maintain sightlines, and modular layouts adapt to changing batch sizes and parts.

How difficult is installation, and can my team do it?

Most facilities can install with basic tools. Anchor brackets, hang track, and attach panels via rollers or grommets. Confirm structure, sprinkler clearance, and level runs, then test panel travel. For large spans or complex ceilings, consider professional install to save time and ensure optimal performance.

How do I clean and maintain spray booth curtains?

Wipe with compatible cleaners and soft cloths; avoid abrasive pads on clear windows. Rinse and air-dry after wash-downs. Inspect hems, welds, and hardware monthly, and replace filters and worn panels as needed. Regular care preserves clarity, reduces dust buildup, and extends curtain service life.

What temperature or UV limits should I know about?

Standard PVC performs well at typical indoor temperatures. Extended high heat, intense UV, or hot tool contact can degrade clarity or flexibility. For warm zones or indirect sunlight, select upgraded compounds or tinted sections. Always verify coating bake cycles and cleaning temperatures against material specifications.

Can I integrate doors, pass-throughs, or equipment cutouts?

Yes. Add zippered entries, strip-door pass-throughs, hose or duct cutouts, and overlap seams for quick access without opening the entire bay. Reinforced edges and clear windows maintain durability and visibility around busy work areas while keeping overspray and dust where they belong.

What comes in a typical kit—curtains only or hardware too?

You can order panels alone or as a complete system with track, trolleys, brackets, and fasteners. Quotes list panel dimensions, materials, window locations, and accessories like floor sweeps, seals, and filter frames. Choose what fits your retrofit needs and existing structure.

How long do paint booth curtains last?

Lifespan depends on overspray load, cleaning frequency, UV exposure, and abrasion. In typical indoor shops, well-maintained panels often last several years. Replace sections that become cloudy, cracked, or chemically damaged. Selecting the right compound and keeping filters fresh extends performance and clarity.

What are typical lead times and shipping methods?

Standard sizes can ship quickly; custom builds add manufacturing time. Lead times usually range from a few business days to a few weeks depending on complexity and order volume. Panels and track are packed to prevent bends or scuffs, with freight selected by size and weight.

Do curtains replace PPE or engineering controls?

No. Curtains improve containment and cleanliness, but they don’t replace respirators, eye protection, or compliant ventilation. Use them as part of a layered safety plan with correct PPE, exhaust, filtration, and spill control. Follow coating manufacturer instructions and your site safety procedures.

Can I move or reconfigure the curtain layout later?

Yes. Track-mounted panels can be rearranged, extended, or parked to adapt to new jobs or equipment. Modular hardware allows you to add sections, change entry points, or convert a partial bay into a full enclosure without rebuilding the entire system, minimizing downtime and cost.

Do you offer color or tint options for visibility and glare?

Yes. Clear windows are standard for sightlines, while tinted or colored sections can reduce glare and help segment zones. Choose combinations that balance visibility, privacy, and lighting in your space. Marking borders or color-coding bays also improves safety and wayfinding on busy floors.

Can these curtains be used for prep, priming, or light sanding?

Yes. Curtain enclosures are commonly used for prep and priming where quick access and easy cleanup are priorities. Pair with proper exhaust and filtration to manage dust and overspray. For heavy production or specific code requirements, use curtains alongside a dedicated rigid booth.

Photo Gallery

Curtain Track

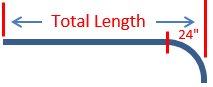

- 16 gauge galvanized steel tracks

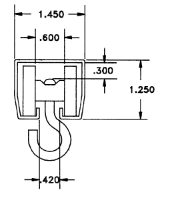

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.