OVERVIEW

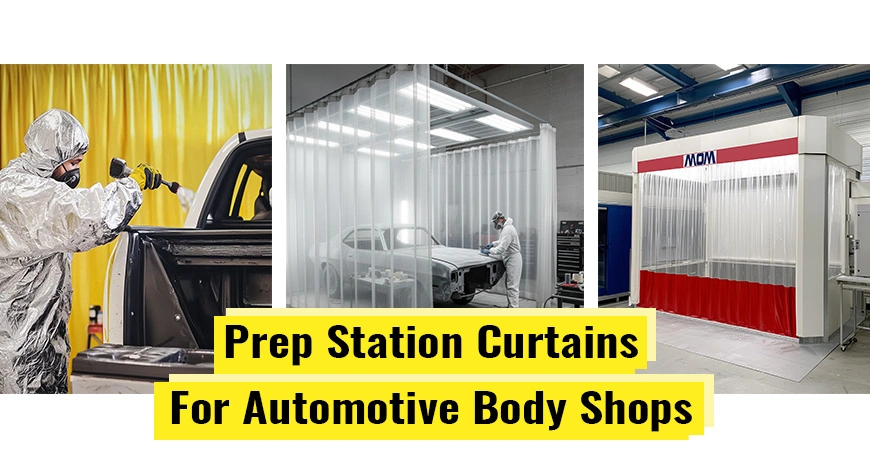

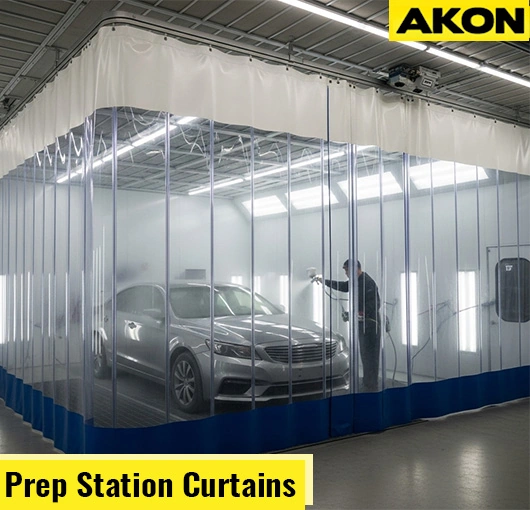

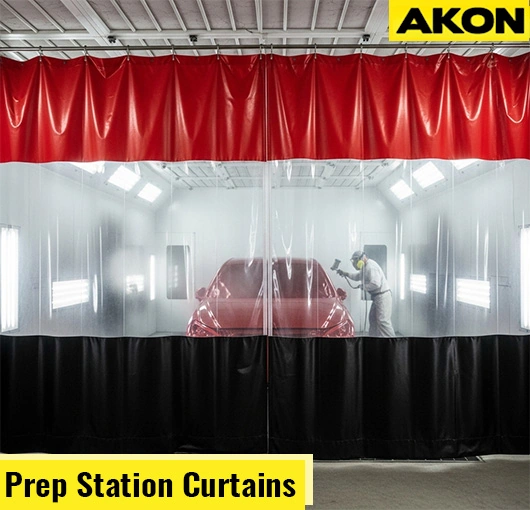

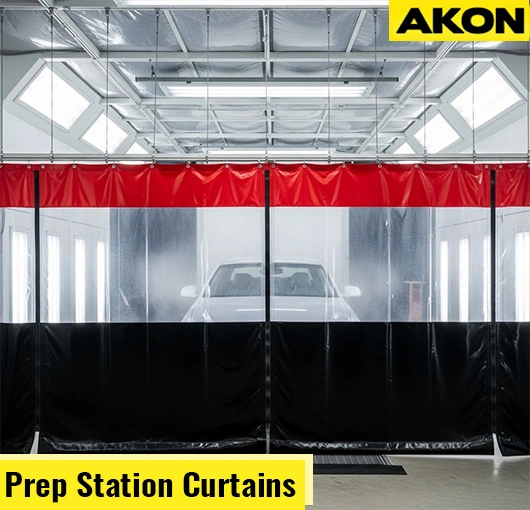

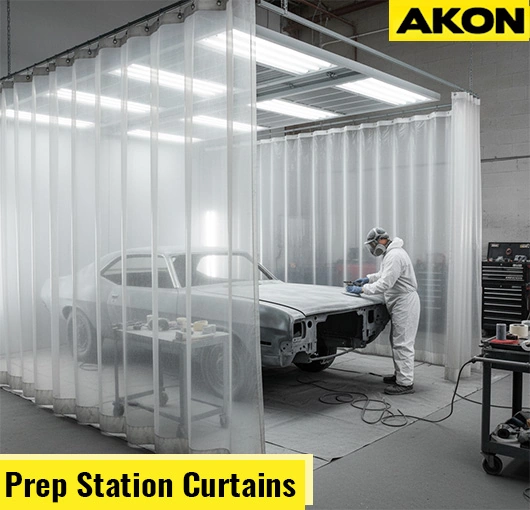

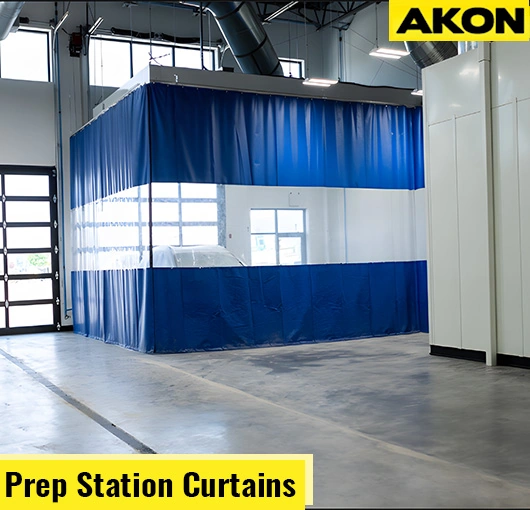

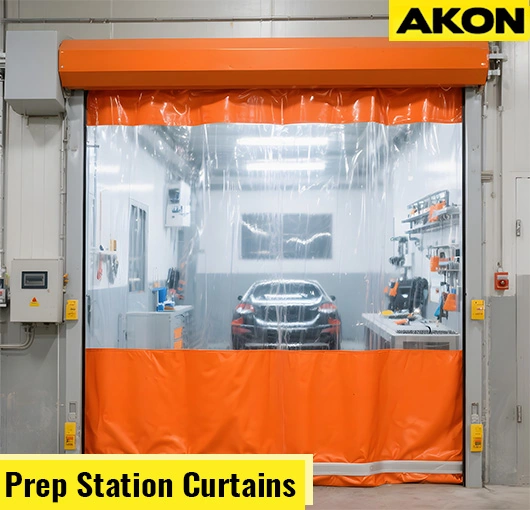

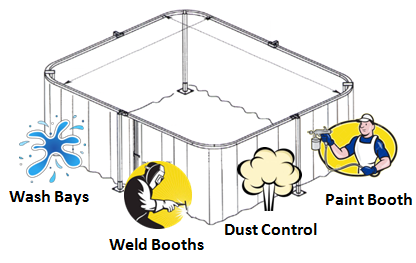

New and Replacement Prep Curtains for Prep Stations. Maximize your floor space and contain paint and water spray with AKON prep booth curtains. The auto body curtains are the ideal solution for prep stations and industrial customers all around the country. Once installed, the curtains create work stations or work stalls that will contain sparks, paint, water overspray, aluminum dust, steel dust and most chemical sprays.

Choose A Style

Create Prep Work Zones In Your Shop

Quick To Deploy And Store

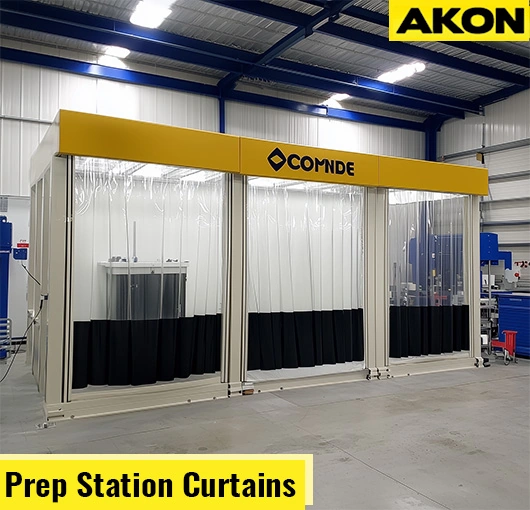

Free-Standing Prep Booth Curtains

Keep Prep Work Areas Clean

The Leader In Body Shop Prep Curtains

Strong With Quick Deployment

Ideal Applications

- Paint prep station curtains

- Prep booth curtains

- Retractable paint booths

- Detailing Wash Bays

- Under Coat Bays

- Grinding and Sanding Bays

- Under Coating Curtains

Benefits

- Less expensive than rigid walls like drywall and panels

- Allow different work processes alongside each other with work cells

- Improve air quality and worker conditions

- Easily roll the prep curtains out of the way when not in use

- The automotive prep curtains meet all fire codes and regulations

- Quick to install and take down and move if necessary

- Five year warranty on the curtains

- And a lifetime warranty on track hardware

Designed For Speed and Flexibility

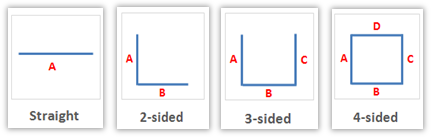

Common Layouts

Curtains for paint prep booths or for any of the other applications mentioned above can be laid out in several different configurations. They can be single sided, double sided, triple sided or four sided to create complete enclosures. You simply inform AKON about your desired prep booth design and we will have it fabricated exactly as you need it.

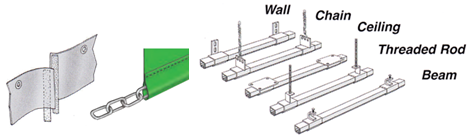

Optional Components

- Floor anchors to secure the prep curtains to the floor

- Many custom colors to choose from to match your facility

- Clear vision panels allow line of sight through the curtains

- Chain weight pocket ensures prep curtain will not blow around

Key Features

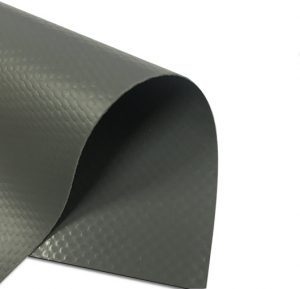

- 18 oz coated vinyl material is standard

- 16 gauge galvanized steel hardware which resists rusting

- Rolling curtain hooks allow for Easy Roll movement

- Hems are reinforcement on edges

- Vinyl is reinforced with polyester scrim for longevity

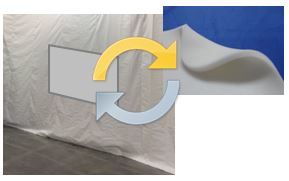

Filter Panels

The auto body prep stations can also feature filter panels in sizes of 4′ x 4′ or 4′ x 2′ to allow for negative pressure generated inside of the curtain enclosure due to ventilation systems. These replaceable curtain filters Velcro onto the curtain and can be replaced if and when they become too clogged to function.

Aluminum Dust

Aluminum dust is now part of new car frames and dealing with that dust is now a critical consideration for auto-body shops. The processing of these aluminum body cars and trucks requires a completely sealed off area. Our aluminum repair enclosure curtains will divide these work areas where grinding is taking place from the rest of the shop.

Maintaining The Curtains

The prep curtains are made from a slick material much like your shower curtain. The material can be easily wiped off when it becomes dusty and washed down when it becomes dirty. If the curtains become really dirty you can wash them down further with a cleaning agent. The curtain wall material is also mildew-proof and resistant to most chemicals. In addition, if they become torn from a sharp object we offer clear patch tape to repair the rip.

Frequently Asked Questions

By separating the prep area from the rest of the space, prep station curtains keep auto body shops clean and running smoothly. These curtains help keep dust, dirt, and paint mist inside, making the work area safer and better organized. When the station is not being used, they slide easily, but when work is going on, they close safely. The tough vinyl doesn't get worn down easily and can handle rough shop conditions. In the FAQ section readers will find answers about how these curtains perform, how they are installed, and what features to look for when choosing the right solution for a body shop.

Prep Station Curtains – Frequently Asked Questions

What are prep station curtains for automotive body shops?

Yes. Prep station curtains are flexible vinyl or PVC barriers used in automotive body shops to create dedicated prep areas by containing dust, overspray, solvent fumes, and debris from sanding or painting operations.

How do prep station curtains improve workflow?

Yes. They let you isolate a specific zone quickly without building permanent walls, enabling faster turnaround, easier cleanup, and better organization of prep tasks within the body shop.

What materials are used in these curtains?

They are made from heavy-duty vinyl or PVC, often reinforced, with optional clear panels or mesh for visibility. These materials withstand solvents, dust, and repeated wash-down or wipe-downs in the shop environment.

Are prep station curtains fire-resistant?

Yes. Many are manufactured with fire-retardant vinyl or meet industry safety standards, making them suitable for automotive body shops where solvent use and polishing operations occur.

Can prep station curtains be installed easily?

Yes. Most systems use track mounts, grommets, hooks or Velcro strips and can be installed without heavy construction, often in hours rather than days.

Do these curtains help keep dust and debris contained?

Yes. They restrict sanding dust, metal filings, paint mist and other particulates to one zone, reducing cleanup in adjacent areas and improving air quality.

Are prep station curtains customizable?

Yes. You can choose size (height/width), material thickness, clear vision panels, color, mounting hardware and sliding or fixed tracks based on your shop’s layout.

Do prep station curtains include clear visibility panels?

Yes. Clear PVC or mesh panels can be included to allow light in and maintain sightlines while keeping the prep area contained from overspray or sanding debris.

Can these curtains retract or slide out of the way?

Yes. Many systems feature ceiling-mounted tracks or rollers so the curtain can be moved aside when the prep area is not in use, maximizing flexibility.

Are prep station curtains resistant to solvents and chemicals?

Yes. The vinyl or PVC material is formulated to resist solvent exposure, spray cleaning, and chemicals commonly used in automotive body shop prep and paint areas.

How do I clean prep station curtains?

Use mild soap and water with a soft cloth or sponge. Avoid harsh abrasives that might damage the vinyl. Regular cleaning maintains clarity of vision panels and material life.

Can I replace panels of the curtain system?

Yes. Individual panels, clear inserts and mounting components can often be replaced without removing the entire curtain system, reducing maintenance cost.

Do prep station curtains reduce noise?

Yes. While not soundproof, their dense vinyl construction helps dampen sound from sanding, grinding and prepping operations, making the workspace quieter.

Are these curtains suitable for vehicle sanitizing bays?

Yes. They can be used in wash-down or rinsing zones in body shops where water, detergent and solvent exposure occur, provided the material is rated for moist conditions.

Do prep station curtains save cost compared to built-in walls?

Yes. They cost significantly less than masonry or framed wall construction, allow faster installation and offer flexibility if your shop layout changes.

How long do prep station curtains last in a body shop environment?

With proper care and moderate use, they can last many years. Their lifespan depends on exposure to chemicals, abrasion, UV and how well they’re maintained.

Can these curtains help improve air quality?

Yes. By containing dust and mist to one area, they make it easier to run localized ventilation, filtration and exhaust, improving air quality for the rest of the shop.

Are prep station curtains compatible with polishing and spray zones?

Yes. They are often used to separate spot-repair zones, sanding bays and final prep before paint, so they integrate well with polishing and spray operations.

Can the curtains be used in high ceilings or large bays?

Yes. They can be built to custom dimensions, include corner tracks and multiple panels to cover large or irregularly shaped bays in automotive body shops.