OVERVIEW

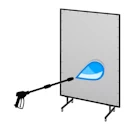

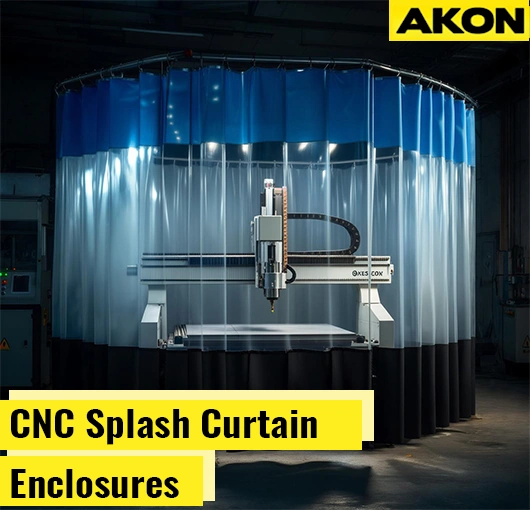

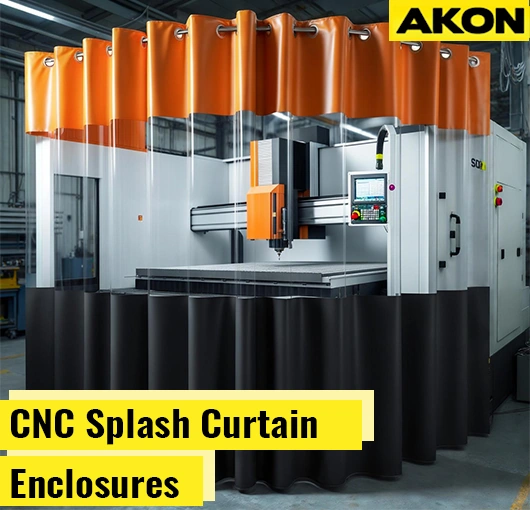

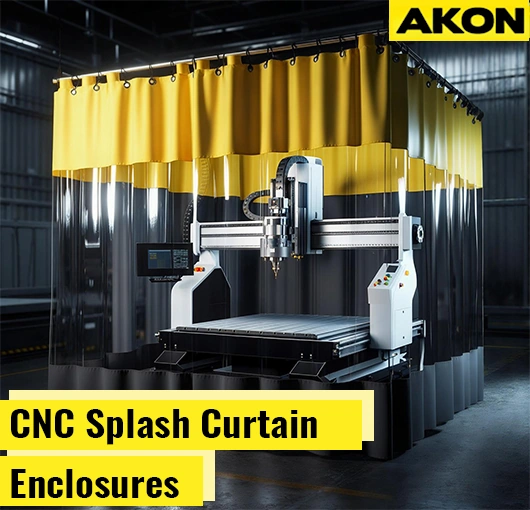

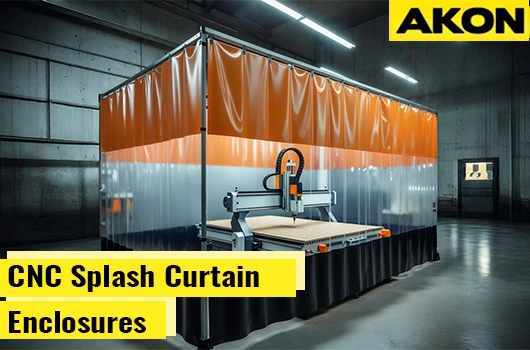

AKON's CNC Splash Curtain Enclosure is a simple and very effective way to improve the safety of your industrial building. Our curtain system is made from heavy-duty vinyl and is custom-made to fit the size of your CNC equipment. It creates a safe area around the work area that keeps coolant spray, metal chips, and other bits of junk inside. The design makes it easy for workers to get to the work area and see what's being done. This makes it a great choice for shops that need to keep things under control without slowing down the work.

Key Benefits

CNC Splash Curtain Enclosure Specifications

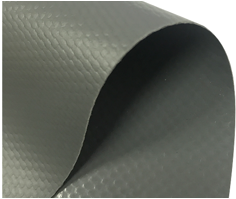

- Made from Heavy-Duty Vinyl. These curtains don't easily tear or crack even when they're constantly exposed to cutting fluids, oils, and debris.

- Designed to fit your machine. Each curtains are custom-sized to fit your CNC machine, making sure that there are no gaps and that the work area is completely covered.

- Simple Setup Process. Installation works with ceiling tracks, wall mounts, or grommets and can be completed quickly without disrupting production.

- Maintain Visual Access. Clear vinyl panels allow operators to monitor machining operations while staying protected from coolant spray and flying debris.

- Enhanced Shop Safety. The barriers contain fluids and chips to prevent slip hazards and keep debris away from walkways and adjacent work areas.

- Smart Investment. These vinyl systems cost less than rigid enclosures while offering easy cleaning and individual panel replacement when needed.

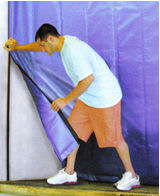

Easy Install

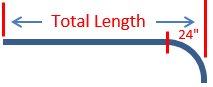

CNC Splash Curtain Enclosures come with grommets at the top making hanging the curtains quick and easy with or without the curtain track.

Inexpensive

CNC Splash Curtain Enclosures are about 1/3rd of the cost of other separation methods such as rigid walls systems and are easy to store.

Separate Workers

CNC Splash Curtain Enclosures are great for keeping your machine safe and keeping your other workers safe from debris and keeping your whole work environment safe.

Heavy Duty

CNC Splash Curtain Enclosures are made from heavy-duty vinyl which doesn't easily tear or crack even when they're constantly exposed to cutting fluids, oils, and debris.

Built to Withstand Coolants and Chemicals

Water and Chemical Resistant

CNC environments are messy by nature. Coolant flies everywhere, oil coats surfaces, and lubricants make the work environment slippery. AKON's vinyl curtain systems are made to last in these tough situations. The material doesn't soak up liquids or react with industrial chemicals, so it won't distort, soften, or start to break down even after being exposed to them for months at a time.

These curtains are really beneficial because they stay protective even when you use them a lot every day. You don't need any special cleaning products or complicated ways to keep them clean. You may just wipe them down with a cloth or a hose. This makes sure that your store runs well from one shift to the next.

Flexible Fit, Tough Protection

Why CNC Splash Curtain Enclosures?

Every CNC setup is different, and permanent walls don’t always work. AKON's CNC Splash Curtain Enclosures are a flexible option that can go around equipment and into small locations. They give you full splash protection without any unsightly gaps. At the same time, they are tough and won't shred, tear, or wear out from being used over and over again. You obtain durability without losing versatility.

Comparison Table: Splash Curtains vs Other Solutions

Choosing the Right Machine Splash Protection

When selecting a solution for containing coolant, debris, or fluid spray around CNC machines or industrial equipment, it's important to weigh the pros, cons, and costs of each option. The table below compares common splash protection methods to help you determine which one best fits your facility’s needs.

| Solution | Pros | Cons | Cost |

|---|---|---|---|

| Rigid Metal Guards |

Extremely durable Permanent installation Ideal for heavy-duty, fixed setups |

High initial cost Difficult to reconfigure Obstructs visibility |

$$$$ |

| Plastic Panels |

Provides limited visibility Moderate splash protection Suitable for basic containment needs |

Becomes brittle over time Not modular or adjustable |

$$$ |

| DIY Tarps & Shields |

Low initial cost Easy to assemble from basic materials Useful for temporary or emergency setups |

Inconsistent fit Potential safety concerns Limited durability |

$ |

| Vinyl Splash Curtains |

Custom fit for any layout Optional clear visibility Chemical-resistant surface Quick installation and repositioning Cost-efficient over time Recommended for most CNC or industrial applications |

No significant drawbacks identified | $$ Best Value |

Which CNC Splash Solution Offers the Best Value?

Strong but Costly and Inflexible

Rigid metal guards are ideal for shops that don’t plan to reconfigure their layout. They’re strong and long-lasting, but expensive and not easy to adapt. If flexibility and cost-efficiency matter to you, this may not be the best fit.

- Estimated Cost: $1,500 or more

- Lifespan: 5+ years

- Pros: Extremely durable, offers permanent protection

- Cons: High upfront cost, difficult to modify or relocate, blocks visibility

Budget-Friendly but Short-Lived

DIY tarp installations might work in limited circumstances, but they don't last long in hectic industrial settings. Over time, they can move, rip, or sag, which puts your team and workspace at risk. Most of them need to be replaced within a few months.

- Estimated Cost: $100–$200

- Lifespan: 3 to 6 months

- Pros: Very low upfront cost, easy to source materials

- Cons: Poor fit, unsafe, short lifespan, looks unprofessional

The Best Value Overall

AKON's CNC Splash Curtains give you the strength and flexibility you need without costing a lot of money. They are made to work in genuine CNC shops, where they can handle coolant, chips, oil, and wear and tear while still being easy to clean and put together. The choice for clear vinyl also keeps everything in sight.

- Estimated Cost: $250–$500

- Lifespan: 2 to 4 years

- Pros: Affordable, durable, chemical-resistant, easy to install, and fully customizable

- Cons: None significant, especially when balanced against performance and cost

Material Options

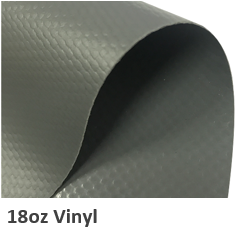

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

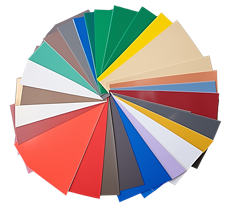

Available in Multiple Colors

Strong Materials

Frequently Asked Questions

Choosing the Right Machine Splash Protection

When selecting a solution for containing coolant, debris, or fluid spray around CNC machines or industrial equipment, it's important to weigh the pros, cons, and costs of each option. The table below compares common splash protection methods to help you determine which one best fits your facility’s needs.

What are CNC splash curtain enclosures used for?

They're used to contain coolant splash, chips, and debris around CNC machines. This keeps the work area cleaner and safer while reducing downtime and cleanup efforts.

Are vinyl splash curtains durable enough for industrial use?

Yes, vinyl curtains are designed for rugged environments. They resist tearing, abrasion, and chemicals, making them ideal for CNC machine enclosures.

Can I customize the size of my CNC splash curtain?

Yes, CNC splash curtains can be custom-sized to fit your specific machine layout or enclosure dimensions for a perfect fit.

Do these curtains help with noise reduction?

Yes, vinyl curtains can help reduce noise levels slightly by acting as a barrier. While not soundproof, they offer noticeable sound dampening.

How do vinyl splash curtains compare to rigid metal guards?

Vinyl curtains are more flexible, affordable, and easier to install or modify than rigid metal guards, while still offering effective containment.

Are vinyl CNC curtains flame retardant?

Yes, most industrial-grade vinyl materials meet NFPA-701 flame resistance standards, making them safe for machine environments.

Can I see through the curtain?

Yes, clear PVC window panels are available and can be integrated into your splash curtain for full visibility without sacrificing protection.

Will the vinyl material crack over time?

No, industrial vinyl is formulated to resist cracking in typical manufacturing environments. Longevity is generally 2–4 years depending on use.

How are CNC splash curtains installed?

They’re typically mounted using overhead tracks, roller systems, or fixed grommets—installation is straightforward and tool-friendly.

Can splash curtains be moved or retracted?

Yes, many systems feature sliding or retractable mechanisms so you can access the machine easily when the curtain isn't needed.

Do vinyl curtains contain coolant mist effectively?

Yes, the non-porous vinyl surface prevents coolant mist and splash from spreading to the work area, helping maintain cleanliness.

Is this material chemical resistant?

Yes, vinyl splash curtains are resistant to most chemicals and solvents commonly used in machining processes.

What is the typical lifespan of a vinyl CNC enclosure curtain?

On average, these curtains last 2–4 years in regular industrial use, depending on exposure to UV, coolant, and handling.

Do vinyl curtains require any maintenance?

Minimal maintenance is needed—just wipe down the surface with mild detergent or water to remove dust, oil, or residue buildup.

How do splash curtains help with OSHA compliance?

They help contain hazards like flying chips and coolant spray, supporting machine guarding and safety requirements under OSHA regulations.

Can I use these curtains in welding or grinding areas?

No, vinyl splash curtains are not designed for high-heat or spark-heavy zones. Use welding curtains or flame barriers for those applications.

Is there a warranty for CNC splash curtain enclosures?

Yes, most manufacturers offer warranties ranging from 1 to 3 years depending on the product grade and usage conditions.

Are these enclosures easy to clean?

Yes, vinyl is non-porous and can be easily wiped down with standard cleaners, making cleanup fast and hygienic.

Do these curtains affect machine operation or access?

No, they are designed to allow easy access to CNC machines when needed. Retractable systems make operation hassle-free.

Can I use these vinyl splash curtains outdoors?

It’s not recommended. While vinyl is water-resistant, long-term exposure to UV and weather can reduce its performance and lifespan.

Photo Gallery

Ideal for Industrial and Body Shops

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

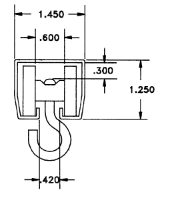

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.