Indoor & Outdoor Noise Control

Ideal For These Users

- Printing facilities

- Metal fabrication shops

- Recycling centers

- Pharmaceutical manufacturing plants

- HVAC equipment enclosures

- Data centers

- Chemical processing plants

- Maintenance and repair workshops

- Manufacturing plants

- Food processing facilities

- Distribution centers

- Wastewater treatment plants

- Power generation stations

- Automotive factories

- Aerospace facilities

- Commercial warehouses

Common Applications

- Air Compressor Enclosure - Help to lower the high-frequency noise in compressor stations.

- Generator Enclosure - Enclose loud standby or portable generators with acoustic barriers or enclosures.

- HVAC Equipment Enclosure - In large buildings, control noise from air handlers, chillers, and rooftop units.

- Stamping Machine Enclosure - Help to reduce impact noise in metal manufacturing spaces.

- Industrial Fans & Blowers - Create constant air movement noise in manufacturing environments.

- Machine Enclosure - Wrap loud machinery such lathes, grinders, and CNC machines in machine enclosures.

- Conveyor Enclosure - In packing and sorting facilities, absorb sound along loud conveyor lines.

- Boiler Rooms - Help to minimise low-frequency noise and resonance from industrial boilers.

- Engines and Turbines - Create isolation zones around power producing installations.

- Test Chambers - Create both permanent or portable acoustic test chambers for product testing.

- Pump Rooms - Help to reduce the noise and echo produced by large volume industrial pumps.

- Work Cells - Should be split using factory walls to isolate noisy operations or lower noise flow-through.

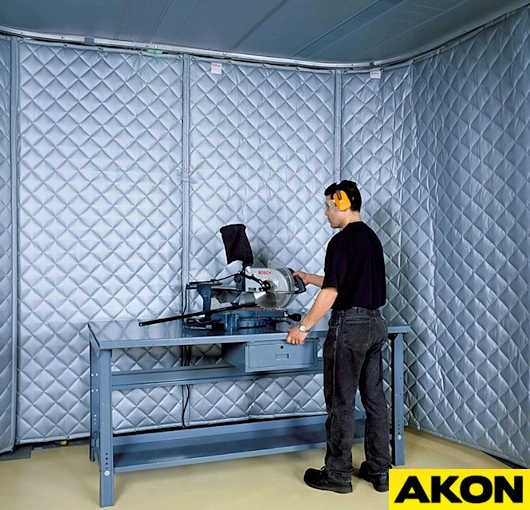

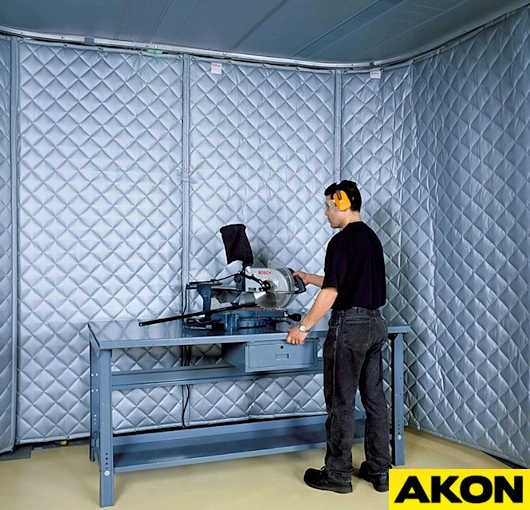

High Quality Sound Panels

High noise reduction coefficient AKON sound reduction panels are flexible for indoor or outdoor noise management. Built with two layers of 1-inch thick acoustical fiberglass batting, quilted with UV-rated threads, and covered in sturdy, weather-resistant polyester facing, these strong panels efficiently absorb sound reflections in any setting. Installed on fences, walls, ceilings, or enclosures, they are perfect for HVAC systems, building sites, machinery rooms, and industrial equipment. Standard 4' x 8' widths or custom proportions up to 4' x 25' with several color possibilities allow panels to be offered in both great acoustic performance and design versatility.

Divide Your Entire Factory

Both safety and production depend on noise between departments being under control in major manufacturing facilities. A industrial soundproof walls built from industrial sound panels can efficiently split a whole manufacturing space. These panels are perfect for isolating louder machines from quieter assembly or office spaces since they are meant to absorb and suppress sound.

Unlike permanent walls, they can be rebuilt should your layout change, and they may be installed quickly using steel supports or existing frameworks. Without compromising flexibility, the end effect is a cleaner, calmer, more regulated workplace. These panels provide a modular, scalable answer whether your required barrier is 30-foot-tall and spans 300 feet or a smaller divider.

Outdoor Sound Blocking Panels

Single or double sound panel walls placed adjacent to loud equipment will help to block outdoor noise at the source. Without completely enclosing the equipment, these weather-resistant panels absorb and deflect sound, therefore lowering noise for surrounding workers and neighbors. Perfect for generators, compressers, or HVAC systems, they are custom-sized and easy to install.

Completely enclose outdoor equipment with specially designed, padded industrial sound panels for demanding surroundings. Four walls and an optional roof make up these weather-resistant enclosures, therefore creating a complete sound barrier. Designed to fit your precise dimensions, they lower noise levels, improve safety, and provide simple access using either hinged or detachable wall panels.

Portable Sound Blocking Panels

Using AKON's Portable Sound Blocking Screens will improve your workstation. For best noise suppression, these modular, movable barriers include 1" thick quilted fiberglass panels with internal loaded vinyl. While safety swing legs provide stability and mobility, quick-connect frames permit variable configurations—standalone or multi-sided enclosures. Perfect for flexible, powerful sound management.

Use Portable Sound Blocking Panels from AKON to surround loud machinery such as air compressors with quick noise control. These movable, modular barriers absorb and block sound with 1" thick quilted fiberglass inside weighted vinyl. Easy setup around loud machinery made possible by quick-connect frames produces flexible, semi-enclosed noise barriers whenever you need them.

Soundproofing Enclosures

For best noise suppression, completely surround loud machinery using specially designed, padded industrial sound panels. Four walls and an optional ceiling in these enclosures help to produce a total sound barrier. Made to meet your precise measurements, they significantly lower noise levels, enhance worker safety, and preserve accessibility by hinged or detachable panels. Perfect for factories, offices, and any setting where machinery noise has to be controlled.

Establish a peaceful haven using our specially made sound enclosures for individuals. With its four padded walls and roof, these buildings block outside noise and provide quiet areas in noisy surroundings. Perfect for offices, warehouses, or workshops when concentrated labor, meetings, or breaks call for solitude from nearby noise sources.

Retractable Soundproofing Walls

Create retractable soundproofing curtain walls by mixing industrial curtain track with our sound panels. This technology provides variable noise control free from permanent obstacles by letting you slide panels open or closed as necessary. Perfect for active industrial settings, it offers complete access as needed and strong sound cancellation when closed.

Make a retractable sound barrier using double side-by-side industrial curtain tracks. This arrangement allows adjustable industrial noise control without restricting access by letting sound panels move past one another like sliding doors. Ideal for noisy factories, it enables rapid reconfiguration—close the panels to prevent noise, or push them away as needed.

Frequently Asked Questions

Industrial noise curtains reduce sound levels in factories, warehouses and manufacturing facilities where loud machinery would distract other workers from different work areas. This solution is a way cheaper option rather than building permanent walls. They are flexible and can be easily moved anywhere needed in case the layout of your production changes constantly. in The FAQ below will discuss more about industrial noise curtains, how to install it and more information you need to know about it these curtains.

Industrial Noise Control Curtains & Soundproofing Panels FAQ

What are industrial noise control curtains?

Industrial noise control curtains are heavy, insulated panels designed to reduce sound in factories, warehouses, and production areas. They block, absorb, and contain noise created by loud machinery and equipment.

How do noise control curtains work?

They use layered materials that absorb sound waves and create a barrier between loud equipment and nearby workspaces. This reduces echo, vibration, and overall noise levels.

What noise reduction rating can I expect?

Most industrial sound curtains provide noise reduction in the 10–15 dB range, depending on material thickness, insulation, and installation.

Are sound curtains the same as soundproof panels?

No. Curtains reduce noise and create flexible barriers, while rigid soundproof panels offer higher acoustic performance for fixed installations.

Can these curtains fully soundproof a workspace?

No. They significantly reduce industrial noise but do not create complete soundproofing. They are designed to manage noise, not eliminate it entirely.

Where are noise control curtains typically used?

They are used around compressors, CNC equipment, generators, stamping presses, pump systems, and other loud machinery to make work areas safer and more comfortable.

Do these curtains help reduce echo?

Yes. The insulated interior absorbs sound reflections, reducing echo and improving acoustic comfort in large open rooms.

Can I customize the size and thickness?

Yes. Curtains are made to your required width, height, and insulation level to match your facility’s noise control needs.

Are noise control curtains fire resistant?

Yes. Most models use flame-resistant vinyl and insulation materials that meet industrial safety standards.

Do these curtains help with temperature control?

Yes. The insulation not only blocks sound but also helps reduce heat transfer and prevent drafts.

Can sound curtains be installed on tracks?

Yes. They can be mounted on sliding tracks, allowing easy repositioning or opening for equipment access.

Are sound curtains easy to install?

Yes. They hang from grommets, track rollers, or mounts and can be installed using common hardware and tools.

Do noise control curtains absorb vibration?

They reduce airborne vibration and sound waves but are not designed to isolate structural vibration coming from machinery bases.

Can I add windows to soundproofing panels?

Yes. Clear or mesh viewing sections can be added for supervision and safety monitoring around loud equipment.

Are these curtains movable?

Yes. Sliding tracks or rolling frames allow the curtains to be repositioned, opened, or stored as needed.

Do noise control curtains require maintenance?

Maintenance is minimal. Regular cleaning and inspections help ensure the materials remain effective and in good condition.

Are these curtains weatherproof?

Most are designed for indoor use. Outdoor-rated versions are available but require additional reinforcement and weather-resistant materials.

Can they be used to enclose entire rooms?

Yes. Many facilities use these curtains to create modular sound-reducing enclosures around noisy machinery or work cells.

How long do industrial noise control curtains last?

With proper use, they last many years thanks to durable vinyl exteriors and impact-resistant insulation layers.

Single Sided

Model: CDS-Quilted-Single

Usable Sides: One Side

Thickness: 1″

Bound Edges: Yes

Grommets: Yes - On perimeter

Panel Sizes: 4’W x 4’H | 4’W x 6’H | 4’W x 8’H | 4’W x 10’H and custom sizes

Price: $

Overview: Designed for use against flat surfaces, including walls or the sides of machinery, AKON's Single-Faced Quilted Fiberglass Panels have Quilted Fiberglass Material (QFM) on one side. For hanging barriers, QFM—lightweight and semi-flexible—offers a mix of sound absorption and noise-blocking ability. These panels frequently reduce sound reflections and reverberant noise within equipment enclosures, rooms, or entire buildings. Often employed with plywood constructions on building sites, they help to minimize reflected noise and enhance general sound management.

Double Sided

Model: CDS-Quilted-Double

Usable Sides: Both

Thickness: 1″ and 2"

Bound Edges: Yes

Grommets: Yes - On perimeter

Panel Sizes: 4’W x 4’H | 4’W x 6’H | 4’W x 8’H | 4’W x 10’H and custom sizes

Price: $

Overview: Double-faced quilted fiberglass panels are ideal for hanging applications. Examples include sound booths, hanging from curtain tracks, mounting to open face fencing, freestanding sound barriers, and more. They also enhance sound suppression, as both sides of the panel are treated to absorb sound.

Quilted - Double Sided With Mass Loaded Vinyl

Model: CDS-Quilted-Double

Usable Sides: Both

Thickness: 2"

Bound Edges: Yes

Grommets: Yes - On perimeter

Panel Sizes: 4’W x 4’H | 4’W x 6’H | 4’W x 8’H | 4’W x 10’H and custom sizes

Price: $$

Overview: Quilted Fiberglass Panels with Internal Mass Loaded Vinyl (MLV) offer a powerful combination of sound absorption and sound blocking—ideal for high-noise applications. These hybrid panels feature a dense MLV core sandwiched between layers of quilted fiberglass, delivering both noise reduction and sound containment in one solution. Designed for both hanging and face of wall mounting, they are perfect for surrounding loud equipment or creating noise enclosures or walls. The quilted fiberglass absorbs echo and reverberation, while the internal MLV blocks sound from passing through—making these panels a top choice for noise control applications where absorbing and blocking sound is important.

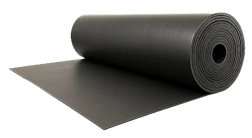

Vinly - Mass Loaded

Model: CDS-Mass-Loaded-Vinyl

Usable Sides: Both

Thickness: 1/4"

Grommets: Optional

Roll Sizes: 54" and 96" wide | custom sizes available

Price: $

Overview: Mass Loaded Vinyl (MLV) is a high-density noise barrier designed to block sound transmission in demanding environments. Ideal for hanging on fences, walls, or framing, MLV is a flexible yet durable material that adds mass to any surface, effectively reducing sound penetration. Unlike quilted porous materials that absorb sound, MLV reflects and blocks noise—making it a perfect solution for noisy areas requiring maximum noise control. Often used behind or between other materials like quilted fiberglass, MLV is essential when meeting site noise ordinances and minimizing disruption to surrounding areas.