Common Questions

Do the sound panels fold up like a shower curtain?

The curtains do not fold up like traditional fabric curtains. Instead, the panels move side to side, similar to a train on tracks. This design is necessary due to their thickness, which is essential for sound absorption. As a result, you have a couple of options if you need to move the industrial sound barrier panels out of the way:

Option 1: Extra Track

Let’s say you have a 20-foot-wide sound barrier wall. If you want to move it completely out of the way, you can order 40 feet of track. This extra length allows you to roll the entire 20-foot wall to the side, much like how a barn door slides along an extended track to fully clear an opening.

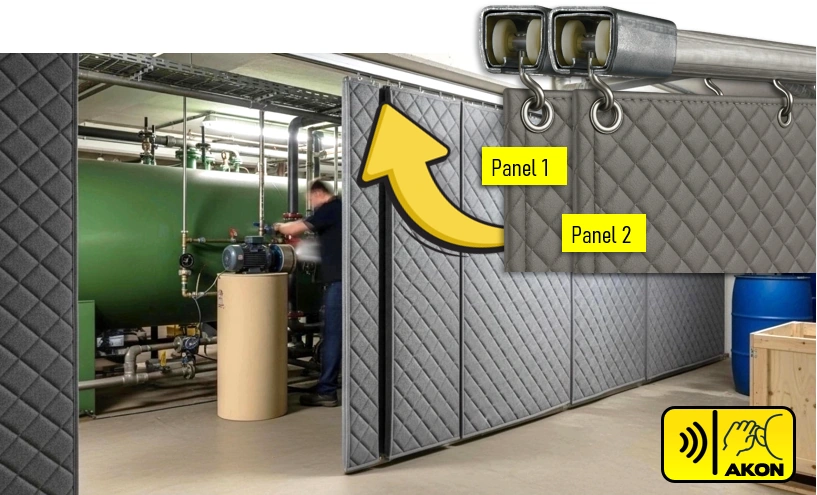

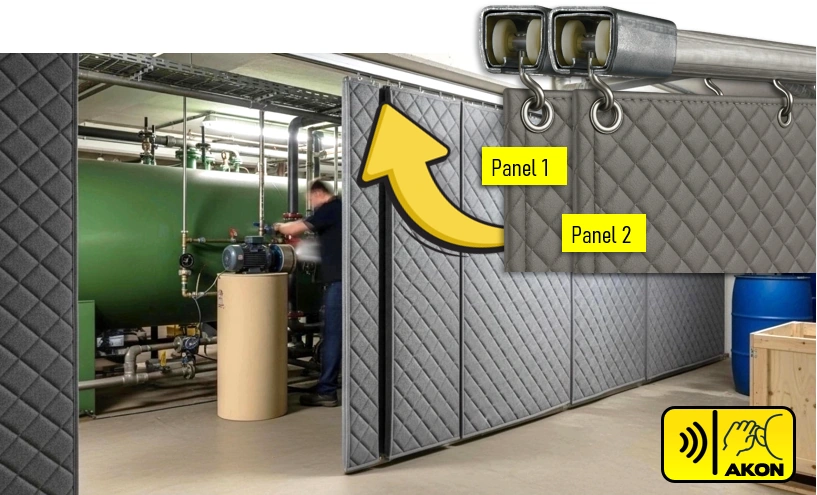

Option 2: Double Track

This setup involves two side-by-side tracks, allowing the panels to slide past one another. You can stack them together along the wall without needing double the track length.

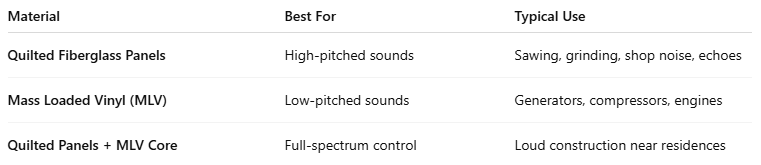

I can't decide if I should use mass-loaded vinyl (MLV) or quilted panels.

Use MLV if your priority is to keep noise from escaping the area and you are not worried about it bouncing back to source. Use quilted panels if your goal is to reduce noise within the area for workers, visitors or nearby operations. For optimal results, some clients combine both materials: MLV for perimeter fencing and quilted panels near the actual noise sources.

How might these panels cut noise?

Comprising soft, porous, open-celled materials, the panels absorb sound waves, therefore lowering ambient noise levels and reverberation duration. In many different work settings, this improves output and communication.

Are the panels custom-made?

The industrial soundproofing panels are both standard and custom-made. We use as much material as we can for your project, which is standard and stocked, then for a small fraction of your project, we custom-cut the material to make it a perfect fit. This gives you an industrial sound-blocking wall or enclosure that is made to your exact size while keeping your cost lower.

Are the panels fire-rated?

Yes, the quieted soundproofing industrial panels are class A fire rated per ASTM E-84.

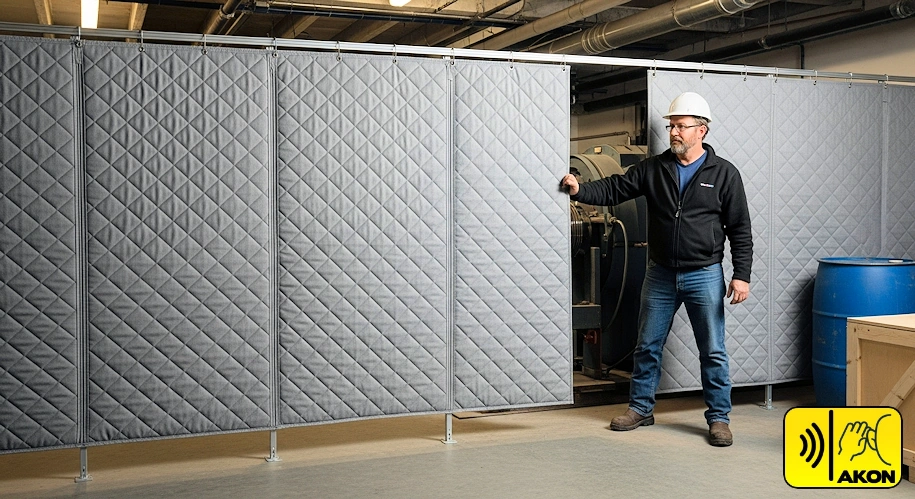

Industrial quilted sound panels are what?

Made from fiberglass or another porous substance, flexible, fabric-faced acoustic remedies called industrial quilted sound panels are In industrial and commercial settings, they are intended to absorb and block sound, therefore lowering echo, reverberation, and general noise levels.

What materials make up these panels?

Fiberglass batting's basic width ranges from 1" to 2". The facings are made from nonwoven porous scrim, silicone-coated fiberglass, or vinyl-coated fiberglass fabric. For durability and looks, diamond or straight stitch patterns, and for maximum sound shielding, some panels also have mass-loaded vinyl barriers inside per special request.

Are they outdoor-useable?

They are outdoor rated when you inform us as we will add a special coating to the panels. These weather-resistant facings, which are silicone-coated, are then ok for outdoor use.

How should I keep these panels neat and maintained?

Maintenance is simple by performing frequent dusting or vacuuming, with spot cleaning stains with a light detergent. Steer clear of strong chemicals that might compromise the face material. For particular cleaning advice, you can ask your AKON representative.