OVERVIEW

Computers, WiFi systems, manufacturing equipment, and testing tools are just some of the electronic devices that are common in today's workplaces. But here's the problem: all of these gadgets make invisible electronic "noise" that can mess with each other, which can lead to equipment failures, data issues, and expensive downtime.

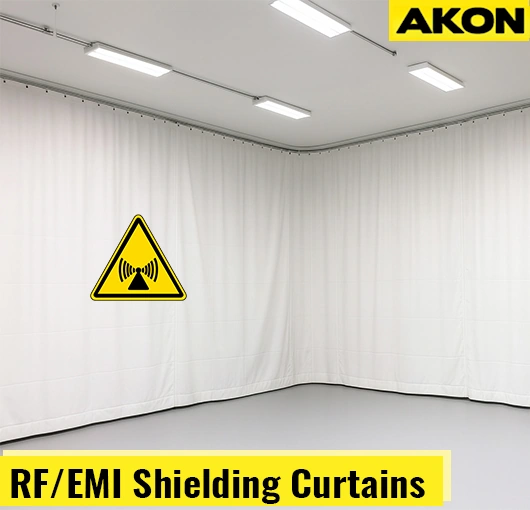

AKON's RF/EMI shielding curtains fix this by making invisible walls that stop electronic interference. They are like soundproof curtains, but instead of blocking noise, they block electronic signals that can mess up your equipment. These special curtains keep delicate electronics safe while still letting you rearrange and move your workspace as needed.

Understanding EMI/RF Risks in Industrial Environments

The increasing number of factories and industrial facilities relying more and more with advanced technologies for their processes are also causing an increased risk in electromagnetic interference (EMI). EMI can disrupt essential operations of a facility and compromise reliability.

Here are some key risk of RF/EMI at your workplace:

- Jammed Signals: EMI can mess up communication networks, corrupting data and making things unreliable.

- Malfunctioning Machines: It causes precision equipment to act up, which creates big delays and quality control problems on the factory floor.

- Unsafe Conditions: Interference with sensitive equipment can create unexpected failures, leading to safety hazards for workers.

- Legal Trouble: If you're in a field like medical devices or aerospace, not meeting EMI standards can land you with huge fines or even product recalls.

- Money Lost: When all of this happens, you have to pay for costly downtime, emergency repairs, and the need to completely redesign systems.

Why RF/EMI Shielding Curtains Are the Best Solution

Most businesses need electromagnetic interference protection and most of the time, permanent walls may not be the best solution for this especially when you're constantly moving machines, updating processes, and reorganizing layouts. This is where RF/EMI shielding curtains actually work with your reality. These curtains give you protection that moves when you do and adapts as your business grows.

Key Benefits:

- Flexibility That Works - Think of these like industrial-strength room dividers you can move around whenever your layout changes. No need to call contractors or spend big money on renovations.

- Budget-Friendly Protection - For under $100 per panel, you get the same interference blocking that those expensive metal rooms provide (and those can run fifty grand or more). It's a no-brainer from a cost perspective.

- Real Results - Don't worry about performance - these block 60-80 dB of electromagnetic interference, which handles pretty much any industrial situation you'll encounter.

- Quick Setup - Forget about construction headaches and downtime. These go up fast, like hanging heavy curtains, and you're back in business the same day.

- Grow With Your Business - Start small and add more panels as you expand, or take some down when you don't need them.

Blocks Interference

Stops electromagnetic signals from messing up your highly sensitive machines and operations.

Cost Effective

Costs way less than building permanent walls to your facility. You can get the solution that you need without breaking the bank.

Separates Area

Lets you divide your area efficiently so you can ensure safety and prevent production delays due to malfunctioning machines.

Custom Made

Made just for you, with your exact measurements and layout as you need them.

Proven Across Industries

Universal Protection

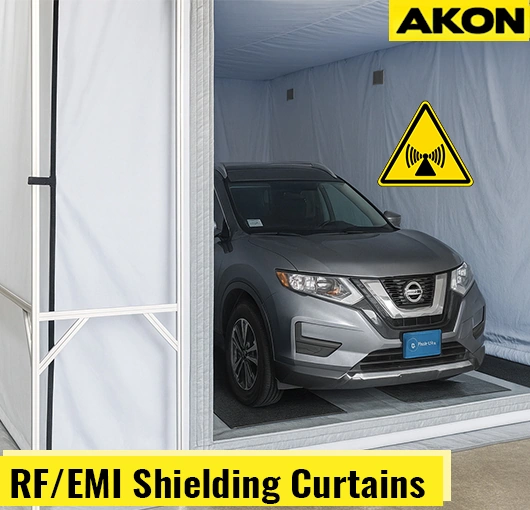

These curtains address real problems in a lot of different applications. Data centers use them to upgrade servers without having to turn all devices off. Manufacturing plants move them around as production lines change while staying compliant with regulations. Research labs set them up quickly for different experiments and testing needs. Medical device companies need portable protection that can keep up with the fast pace of product development.

These curtains can be used for a variety of purposes, such as running servers, making products, doing research, or developing medical devices. They can be changed to fit your needs without having to install them permanently.

Real Industrial Performance

Why AKON'S RF/EMI Shielding Curtains?

AKON's RF/EMI Shielding Curtains are made of the same high-quality conductive materials that expensive permanent walls are made of. They stop electromagnetic interference from 85 to 100 dB, which is a lot of protection that keeps your sensitive equipment working well. The difference is that you don't have to stick with one layout forever.

Your equipment is safe no matter what you're doing, whether it's running manufacturing lines, data servers, or lab tests. You get industrial-strength electromagnetic shielding that works in tough situations and lets you change your setup when your business needs change.

Comparing RF/EMI Shielding Solutions

Electromagnetic interference can cause real problems in factories and labs, so choosing the right protection matters. Some options are heavy and permanent, while others are light and easy to move. Each has its own strengths, costs, and limits. What works for one shop may not fit another. The table below lays out four common choices side by side so you can see the differences at a glance. It covers how each solution is installed, what it costs, and where it works best. This way you can make a clear, practical decision for your own setup.

Which RF/EMI Shielding Curtain Solution Offers the Best Value?

Maximum Protection but High Cost

Permanent walls work great for companies with big budgets and doesn't change their workspace layout regularly. You get the strongest possible electromagnetic protection through this solution, but you'll have to pay a fortune to get it built in custom for your facility. They are mostly ideal for military facilities, high-security government labs, aerospace testing with extreme EMI requirements.

- Estimated Cost: $75,000 to $250,000 or more

- Installation Time: 3-6 months

- Pros: Best possible shielding, permanent fix, looks professional

- Cons: Expensive, inflexible and could cause delay in your production during installation

Smart Protection That Works

AKON's RF/EMI Shielding Curtain systems make sense for workspace that needs solid electromagnetic protection without paying huge amount of money. This is also ideal if you are looking for a solution that you can modify from time to time. You get reliable performance plus the freedom to change things up when your business layout changes. They are most commonly used in manufacturing plants, data centers, research labs, medical device companies, any business that needs flexibility.

- Estimated Cost: $500 to $5,000 for most setups

- Installation Time: Same day

- Pros: Save 90% on costs, change anytime, professional protection, goes where you go

- Cons: Need occasional cleaning, slightly less protection than permanent walls

Frequently Asked Questions

If you're dealing with electromagnetic interference and wondering whether these curtains could work for your business, you probably have questions. We've answered the most common things business owners ask when they're trying to figure out if RF/EMI shielding curtains are right for their situation. These answers cover how well they work, what they cost, and whether they'll actually solve your specific problems.

RF/EMI Shielding Curtains – Frequently Asked Questions

What are RF/EMI shielding curtains and how do they work?

They’re flexible barriers that block radio frequency and electromagnetic interference. Conductive fabric layers reflect and absorb RF energy, creating a shielded zone for testing, RFID isolation, secure communications, or equipment protection. Compared to rigid rooms, curtains are lighter, modular, and easier to reconfigure for changing layouts or temporary needs.

How much attenuation do these EMI curtains provide?

Expect high attenuation. Single-layer designs typically average about −70 to −75 dB from roughly 400 MHz to 18 GHz, while double-layer designs can reach about −85 to over −100 dB across similar ranges. Actual performance depends on layout, seams, grounding, and openings such as doors or pass-throughs.

What materials are used in RF blocking curtains?

Most use a tightly woven ripstop nylon plated with silver, copper, and nickel, lightly coated for durability. This conductive fabric delivers low surface resistivity and stable shielding across wide frequencies. Optional liners—like ESD, sound-reduction, or outdoor skins—can be added without sacrificing the core RF/EMI shielding function.

What’s the difference between single-layer and double-layer curtains?

Single-layer is lighter and more economical for moderate shielding needs. Double-layer adds mass and additional conductive paths for higher attenuation, especially at challenging frequencies. Choose single-layer for general RF isolation or step up to double-layer when pre-compliance testing or stricter electromagnetic compatibility targets are required.

Can I use RF/EMI curtains for RFID isolation or scanner tunnels?

Yes. Curtains and strip styles create controlled RF zones that reduce stray reads and crosstalk around RFID tunnels and conveyors. Strip curtains allow easier product flow while maintaining shielding, making them ideal for assembly lines, logistics checkpoints, and automated scanning where quick pass-through access matters.

How do strip curtains compare to solid RF shielding curtains?

Strip curtains enable frequent pass-through with minimal disruption, which is great for production lines. Solid panels offer more continuous coverage and are preferred when maximum shielding and fewer openings are required. Many facilities combine both: solid walls for perimeter control and strips at access points or material entries.

Do you offer full RF/EMI shielding enclosures?

Yes. Modular enclosures provide room-like shielding at a lower cost than rigid chambers. They’re portable, reconfigurable, and suitable for EMC pre-compliance, wireless device testing, temporary shielding, and secure communications. Enclosures pair with shielded doors, vents, and cable pass-throughs to maintain attenuation while enabling daily operations.

Are there window or equipment covers for targeted RF shielding?

Yes. Custom RF/EMI covers for windows, cabinets, and machines deliver localized shielding without building full rooms. They attach with grommets, magnets, or hook-and-loop for easy removal and storage. They’re a cost-effective way to protect sensitive areas, screens, or openings where leakage commonly occurs.

Do I need grounding or copper tape with EMI curtains?

Usually yes. Proper grounding and conductive tapes help bond panels, tracks, and adjacent surfaces, reducing leakage at seams. Ground straps and foil tape improve continuity, particularly around doors, frames, and utility penetrations. Good grounding practices are essential to achieve consistent, repeatable RF shielding performance.

What mounting and track options are available?

You can choose ceiling-hung track, free-standing frames, or static mounts. Modular steel tracks with roller hooks make panels easy to open and re-position. For drop ceilings, cable or chain supports keep installs clean. Free-standing frames are perfect when overhead mounting isn’t possible or structures can’t be penetrated.

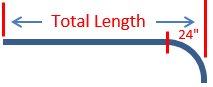

How hard is installation and can the track be cut on site?

Installation is straightforward. Tracks bolt together with simple hardware and can be field-cut with common tools for exact fit. Support spacing is typically a few feet to limit deflection. Standard grommet spacing makes hanging simple, and panels can be removed or reconfigured as needs change.

Are these RF shielding curtains compliant and fire-rated?

Yes. Conductive fabrics are commonly RoHS compliant, and curtain assemblies can use materials that meet NFPA-701 for flame resistance. Always confirm ratings on your quote, especially for labs, cleanrooms, or commercial installations where local codes and safety standards require documented compliance.

Do you offer ESD, sound, or outdoor liners for EMI curtains?

Yes. ESD liners add antistatic protection for electronics handling. Sound liners reduce noise in test areas. Outdoor skins improve weatherability for temporary exterior use. These liners integrate with the base RF fabric, helping you address multiple environmental and safety requirements in a single solution.

How do I measure width and height for a correct fit?

Measure the span you need to cover and the floor-to-mounting height. Tracks are typically the exact width; curtains are made wider for proper drape. Many installs subtract a few inches for hardware clearance unless you request floor contact. Provide slope dimensions if ceilings aren’t level.

Can RF/EMI curtains include vents, doors, or cable pass-throughs?

Yes. Add shielded vents for airflow, specialized doorways for frequent access, and filtered pass-throughs for power or data. These features preserve attenuation while supporting daily work. During quoting, specify equipment locations and traffic flow so penetrations are sealed and placed where they won’t compromise performance.

How do RF curtains compare to rigid RF shielded rooms?

Curtains are more affordable, faster to install, and easier to relocate. Rigid rooms can deliver maximum, permanent shielding but cost more and take longer. If your test profile evolves, modular curtains give you flexibility and quick reconfiguration while still achieving strong attenuation for many use cases.

Are the materials tested to recognized RF standards?

Yes. Shielding effectiveness is typically validated using methods based on IEEE-299 or similar, often with independent lab data for representative assemblies. Ask to review test reports at your target frequencies and confirm whether data reflects single-layer, double-layer, or full enclosure configurations.

How should I clean and maintain RF/EMI shielding curtains?

Use gentle, non-abrasive cleaning methods recommended for coated conductive fabrics. Avoid harsh solvents that could damage plating or coatings. Inspect seams, grounding points, and high-traffic edges periodically. Proper handling and storage help preserve attenuation and extend service life in busy production or lab environments.

What customization options can I specify for my application?

You can choose single or double layers, add ESD or sound liners, select colors, specify grommets, magnets, or hook-and-loop, and include grounding straps, copper tape, vents, or enclosure doors. Layouts can be single-, double-, or four-sided—and scaled for windows, machines, or full rooms.

Is there a warranty for RF/EMI curtains and hardware?

Yes. Robust programs typically include multi-year coverage on curtains and a long-term or lifetime warranty on hardware. Exact terms vary by configuration and usage environment—review your quote for fabric coverage, track components, and accessories like rollers or fasteners.

Photo Gallery

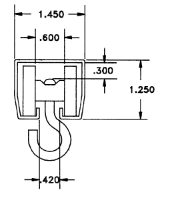

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.