OVERVIEW

Akon can provide your food processing facility with USDA approved wash down curtains. These curtains are designed with non-porous PVC materials which eliminate the opportunity for bacteria to grow and contaminate the products. The stainless steel curtain track is also specially designed as to not allow any debris contamination to build up. The combination of unique features in these USDA wash down curtains improves plant sanitation and reduces downtime on the line.

Designed For Speed and Flexibility

Key Features

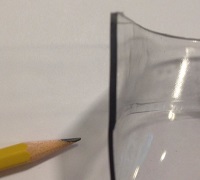

Slick Surface

The materials are specifically designed to be “slick” which will shed solutions and soils, unlike porous materials.

No Stitching

There is no stitching which is commonly used for the hems. A stitched hem can allow debris to get under the fold which leads to bacteria growth.

Form Any Shape

The curtains have the ability for any shape. This allows the USDA curtain to be moved seamlessly around equipment.

Wash Down Flexibility

USDA Curtain Benefits

- Greatly improves plant sanitation

- Prevents cross-contamination between equipment

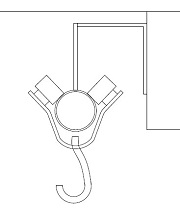

- Specially designed trolley eliminates the collection of debris

- Water that is sprayed onto equipment is confined to that area

- USDA wash down curtains allow for just the area around the equipment to be cleaned

- Eliminates expensive downtime

Sanitation For Washdowns

Food Processing Curtains

Using curtains for food processing in a wash down setting requires careful attention to layout and function. AKON has a lot of experience in utilizing these food grade curtains to their fullest extent. We know that any sanitation curtains that are properly installed will increase your efficiency and decrease your downtime.

Brewery Sanitation Curtains

In addition to our clean screen curtains being used for food processing facilities, brewing facilities also can benefit with the use of sanitation divider curtains. The curtains separate the kettles and fermentation vessels to contain any splashing that may occur during the transferring of liquids. They also provide a sanitary divider for wash down after the brewing process has completed.

Meets Required Codes

Title 21 CFR Approved

The USDA passed the onus of compound compliance/approval to be under FDA provisions, specifically Title 21 CFR (Code of Federal Regulations). Since the USDA does not approve equipment or materials, we have material that meets CFR 21, which ensures that the compounds used are FDA certified raw materials. The AKON curtains are Title 21 CFR compliant and carry a UFL-94 Fire Cert.

CFIA Approved

In addition to meeting USDA standards, the curtains also meet Canadian Food Inspection Agency or CFIA approval. The CFIA is much like the USDA in the United States. Their purpose is to ensure the health and safety of food and food production. Our curtain material has been sent to the CFIA for a full review and it now has their seal of approval.

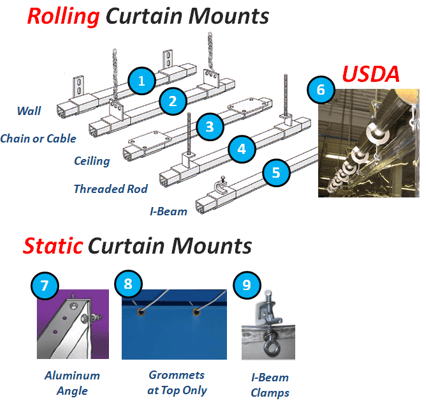

Stainless Steel Hardware

Hardware

The mounting hardware is a stainless steel tubular design with rounded corner curtain carriers. This design allows for water and debris to easily roll off the hardware. Unlike C channel hardware which could collect debris and potentially harbor bacteria.

Wall Mount

For areas where you cannot support the track from above there is a side wall mount attachment. This allows the hardware to be attached to a vertical surface should there be obstructions from above.

Radius Corners

Hard corners or radius corners can be added to the USDA grade hardware. Standard corners are 24 inch and 12″ 90° radius with the ability to make almost any radius your design requires. The mounting tabs can be welded on or shipped loose.

Stainless Steel Grommets

Stainless steel grommets with are placed every 12 inches at the top of the curtain for hanging. The top hem is double folded and heat sealed for additional strength. Grommets can also be placed on the vertical edges.

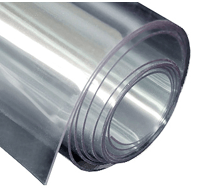

40mil Curtains

40 Mil Clear Vinyl PVC is used for all USDA and CFIA wash down clean curtains. The material is made of compounds that meet federal requirements for incidental contact with meat, poultry, and dairy products.

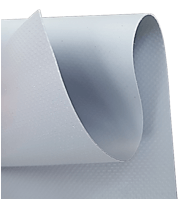

18oz Curtains

When clear is not ideal then use our opaque white all heat sealed curtains. Meets FDA requirements AS/NSZ 4020:22005 & SI-5452 made for safe contact with food. Same USDA quality with non-see through white color.

Frequently Asked Questions

Food processing facilities deal with strict sanitation rules that regular industrial curtains cannot pass. Standard curtains have stitched hems where bacteria grows, porous materials that trap dirt, and hardware that collects nasty stuff during cleaning. USDA approved curtains fix these issues with heat sealed seams instead of stitching, non-porous PVC that sheds water and chemicals, and stainless steel hardware designed to stop bacterial growth. Meat plants, dairy operations, and breweries use these to contain equipment washing without spreading contamination everywhere. This FAQ covers what sets these apart from regular wash curtains, whether the material really stops bacteria, and how stainless steel beats regular galvanized hardware for keeping things sanitary.

USDA Wash Down Curtains – Frequently Asked Questions

What are USDA wash down curtains used for?

USDA wash down curtains are used to create sanitary zones that comply with USDA hygiene standards. They help contain water, cleaning agents, and debris during washdown processes in food plants, processing facilities, and sanitation areas.

Are USDA wash down curtains USDA-approved?

Yes, they are designed using USDA-accepted materials that meet hygiene, cleanability, and moisture-control requirements for regulated processing environments.

What materials are USDA wash down curtains made from?

They are made from smooth, non-porous PVC or coated vinyl that resists moisture, bacteria, staining, and chemical cleaning solutions used in USDA-regulated facilities.

Do USDA wash down curtains support high-pressure cleaning?

Yes, these curtains are built to withstand high-pressure washdown and frequent sanitation cycles. The materials resist cracking, tearing, and water absorption.

Can USDA wash down curtains prevent cross-contamination?

Yes, they help separate food zones, sanitation areas, and processing lines. This reduces the risk of cross-contamination during cleaning and washdown procedures.

Do the curtains include clear vision panels?

Yes, clear vinyl windows can be added for visibility and supervision while maintaining separation and compliance with USDA cleanliness expectations.

Are these curtains customizable?

Yes, they can be customized to any width, height, window layout, color, and hardware configuration to match facility requirements and sanitation workflows.

How are USDA wash down curtains installed?

They can be mounted using stainless-steel tracks, cable systems, or wall-mounted brackets. These hardware options are designed for washdown and corrosion resistance.

Can the curtains withstand chemical sanitizers?

Yes, they are resistant to chlorine, bleach, quaternary sanitizers, degreasers, and detergents commonly used in USDA cleaning processes.

Are USDA wash down curtains fire-rated?

Most USDA wash down curtains meet industrial fire-retardant standards. Fire ratings can be specified to meet facility codes and requirements.

Do USDA wash down curtains support temperature control?

Yes, insulated options are available for facilities that require thermal separation, refrigeration control, or energy management.

Are replacement sections available?

Yes, individual panels or window sections can be replaced without removing the entire curtain system, reducing maintenance time and cost.

Can USDA curtains be used in meat and poultry plants?

Yes, USDA wash down curtains are specifically designed for meat, poultry, seafood, dairy, and other food-processing industries with strict sanitation standards.

Do the curtains help control overspray?

Yes, they contain washdown overspray, reducing cleanup time and protecting equipment and workers from unnecessary exposure.

Can these curtains be used outdoors?

Yes, with UV-resistant materials and stainless hardware, USDA wash down curtains can be used in outdoor washdown or food-handling areas.

How long do USDA wash down curtains last?

They typically last 3–7 years depending on washing frequency, chemical exposure, and environmental conditions inside the facility.

Do the curtains help with OSHA and USDA compliance?

Yes, they help facilities maintain controlled washdown zones, reduce hazards, and support regulatory cleanliness and separation requirements.

How do I clean and maintain USDA wash down curtains?

They can be cleaned using approved USDA sanitizers, warm water, and detergents. Their smooth surfaces prevent buildup and support fast, efficient cleaning.

Can USDA wash down curtains divide large processing areas?

Yes, they can divide open processing rooms into multiple sanitary zones, improving workflow and reducing contamination risk.

Photo Gallery

40 Mil Clear

- 40 mil USDA Grade Flexible PVC - Non-Porous

- Grommets every 12" located at the top of the curtain - Stainless Steel

- Grommet hem is double thick for additional strength

- Hems are heat sealed to prevent bacteria growth

- Colors: Clear only

- Double polished

- Operating temperature: -20° to 140°F

- Made for safe contact with food

- Fire retardant

- CFIA Certified

- Title 21, SI 5113 Certified

18 Oz White

- 18 oz USDA Grade Flexible Vinyl

- Grommets every 12" located at the top of the curtain - Stainless Steel

- Grommet hem is double thick for additional strength

- Hems are heat sealed to prevent bacteria growth

- Colors: White

- Operating temperature: -55° F to 160° F

- Made for safe contact with food

- Fire retardant

- CFIA certified

- Title 21, SI 5113 certified

- For this material please use our custom quote form