OVERVIEW

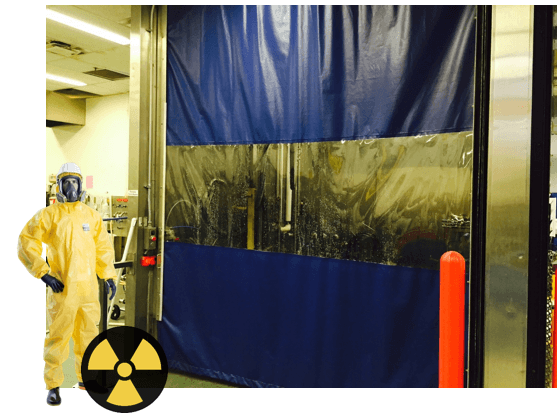

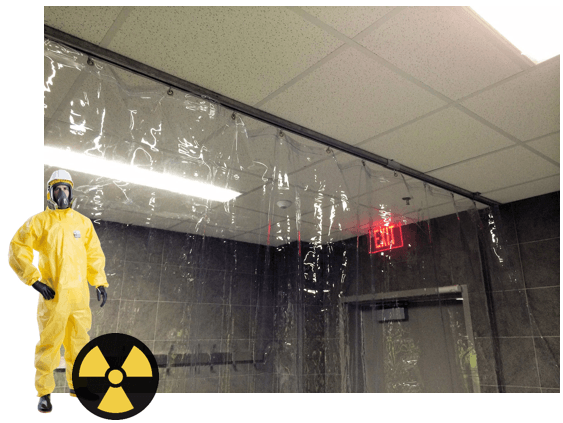

Contamination in the workspace can be dangerous for the health of workers and clients alike. Because of this, any company or facility that handles hazardous chemicals must prepare in advance. One way to do so would be with AKON’s custom made decontamination curtains. They will keep dangerous materials inside and protect the environment outside your working facility. Whether you need them for a food factory, laboratory, the hospital’s special emergency room, or elsewhere, the curtains will help in maintaining a safer environment for all. You will be able to separate a large room into different zones, each with its own type of operation.

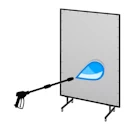

Contamination Spray Containment

Easy Install

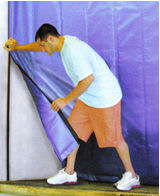

The curtain walls come with grommets at the top, making hanging these contamination curtains quick and easy. Minimal tools are required.

Environmental

Protecting the environment is critical when contamination takes place. These curtains are very quick to deploy either side to side or by rolling them down.

Protects Bystanders

Chemical curtain walls are ideal for protecting bystanders from any dangerous chemical sprays that present a safety hazard.

Physical Barrier

The curtains form a physical barrier in almost any design you need as it relates to your application and decontamination needs.

You Control Hazardous Situations

The decontamination curtains will divide the workspace into different compartments and isolate them. By doing this, you can store different materials, make private spaces, and keep the work away from other rooms. The custom made decontamination curtains are perfect for chemical, medical, and environmental industries. You can create an entire enclosure or put the curtains at the entrance of a specific room. By doing this, you can continue to conduct specific operations in specific rooms without worrying the materials in one area could negatively affect the entire facility.

Preventing cross-contamination is of vital importance in the food industry. You will also have temperature control. Precise separation is important for both the workers’ health and the foods’ freshness. The curtains will contain light which can cause damage to some commodities. Specific products like fruits, cheese, medicine, or soft drinks could get spoiled in no time if direct sunlight shines towards them.

By placing such barriers, you will prevent any type of harmful pollution from reaching the outside environment or other rooms within the building. Every compartment will function without causing interferences to its neighbors and without being affected by them either. The decontamination curtains are also great at helping you maintain an organized procedure, as you can put custom signs which direct workers.

All AKON decontamination curtains are custom made. You have a variety of options when choosing the size, dimensions, colors, mounting options, accessories, and more. The curtains will offer strong protection without blocking your way. Airlocks will make it easy to transport large equipment. You will also be able to create secure access points for the transportation of contaminated items. No material will enter or leave the area without your knowledge. The curtains will also contain non-chemical nuisances such as dust, odor, and moisture.

Material Options

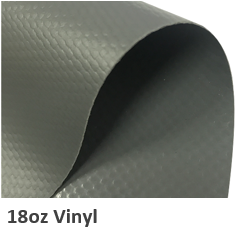

18 oz Reinforced Vinyl (standard)

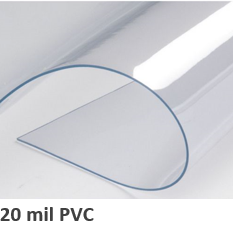

20 mil Clear PVC For Clarity

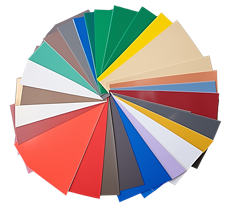

Available in Multiple Colors

Strong Materials

Be Prepared And Ready

Decontamination Curtain Benefits

- Inexpensive unlike fixed walls

- You can quickly deploy them with an industrial roller curtain track

- You have different colors to choose from so your new curtain can nicely match your facility

- The working conditions will improve greatly

- Protection against hazardous chemicals, temperatures, light, moisture

- You can quickly move them away

- You can quickly clean them

- It is possible to re-purpose them for other compartments

- Ability to purchase more curtains and attach to existing curtains

- Divide work areas quickly

- Easy movement through facility rooms

- Industrial curtains improve worker safety

- Contain air migration, odors, dust, overspray

- Custom made with your sizes, dimensions, colors, and more

- Lifetime warranty on all hardware and 5-year warranty on curtains

Decontamination Curtain Features

Our decontamination curtains offer a safe working environment for any facility. Their superior protection will keep hazardous chemicals in check. The features include:

- Durable 18oz Vinyl reinforced with a polyester mesh scrim

- Clear 20mil Vinyl vision panel to allow a line of sight

- Vinyl meets NFPA 701 & California State Fire Marshall Standards

- Strong 16 gauge galvanized or stainless steel track which resists rusting

- Hemmed edges for a clean finished look

- Resistant to different dangerous chemicals

- Every Curtain has a 5 year Warranty!

- The Hardware has a Lifetime Warranty!

You have a great choice of layouts as well. We can supply you with any type you wish. Some common configurations can include straight, 2-sided, 3-sided, 4-sided, and multiple straights. You can make a sketch and submit it in our request-a-quote form (click the yellow button below).

Curtain Options

Curtain – Optional Components

You can change the way your custom curtain looks in different ways. Choose a unique color, texts, and more. The bonuses include:

- Choosing between different colors

- You can also add warning signs on your decontamination curtains to prevent anyone entering from the outside

- Chain weights will keep the curtains stable and prevent hectic movement

- You can ask for vision panels which will allow a clear line of sight

- By using floor sweeps, it will help control contaminated water from migrating to the outside zone

- We can also include walk through strip doors

Frequently Asked Questions

Building permanent decontamination rooms costs massive amounts and takes months of construction that shuts everything down. Decontamination curtains create isolation zones quickly without that mess or expense. Hospitals deploy them for contamination emergencies, food plants separate clean areas from raw material zones, and labs contain chemical spills before they spread. The thick vinyl resists most industrial chemicals and cleans up easily after exposure. These slide on tracks or roll down depending on the space. This FAQ covers which chemicals the vinyl handles, how fast these deploy during emergencies, and what pass-throughs work for moving equipment between zones.

Industrial Decontamination Curtains – Frequently Asked Questions

What are industrial decontamination curtains used for?

Industrial decontamination curtains are used to create controlled washdown or decontamination zones that contain water, chemicals, contaminants, and debris. They help isolate equipment, personnel, and sensitive areas during cleaning and decon procedures.

What materials are decontamination curtains made from?

They are typically constructed from heavy-duty coated vinyl, PVC, or polyurethane-laminated fabric designed to withstand harsh chemicals, repeated washdown, and high-pressure sprays.

Are decontamination curtains waterproof?

Yes, the materials used are fully waterproof and engineered to prevent leaks and runoff. This helps contain contaminated water during washdowns and decon processing.

Can industrial decontamination curtains withstand chemicals?

Yes, most models resist common disinfectants, solvents, acids, alkaline cleaners, and industrial chemicals used during decontamination procedures.

Do decontamination curtains help with airborne contamination?

They help limit directional spray, splatter, and particulate movement, but they do not replace ventilation or filtration systems designed for airborne hazards.

Are clear windows available for visibility?

Yes, clear vinyl or polycarbonate window panels can be added to allow monitoring, supervision, and natural light while keeping the decontamination zone sealed.

Can decontamination curtains be customized to fit my facility?

Yes, they can be customized in height, width, thickness, materials, window placement, color, and mounting hardware to match your specific washdown area or decon protocol.

How are industrial decontamination curtains installed?

Installation typically uses ceiling tracks, stainless steel hardware, cable systems, or wall mounts. Most installations can be completed using common tools.

Do these curtains withstand high-pressure washdown?

Yes, they are designed for high-pressure washdown environments found in processing plants, food facilities, laboratories, and industrial decontamination bays.

Are insulated versions available?

Yes, insulated curtain options are available for temperature-controlled decontamination zones or areas needing thermal separation.

Can decontamination curtains be moved or reconfigured?

Yes, when installed on track systems, they can slide, open, or reconfigure to accommodate different workflows and decon procedures.

Are the curtains fire-retardant?

Most decontamination curtains meet fire-retardant requirements for industrial use. Specific fire-ratings can be requested depending on facility codes.

Can these curtains help with regulatory compliance?

Yes, they support OSHA, EPA, and facility hygiene requirements by providing defined containment zones and minimizing cross-contamination during cleaning.

How do I clean and maintain the curtains?

They can be cleaned using mild detergents, disinfectants, and water. Routine maintenance includes rinsing off chemicals and inspecting seams and hardware.

Are replacement panels available?

Yes, individual panels or window inserts can be replaced without removing the entire curtain system, reducing downtime and long-term costs.

Are industrial decontamination curtains suitable for outdoor use?

Yes, if ordered with UV-resistant coatings and corrosion-resistant hardware, the curtains can withstand exposure to weather and outdoor decontamination processes.

Do the curtains help control water runoff?

Yes, their waterproof construction and containment design help manage washdown runoff, reducing contamination spread and improving drainage control.

Do decontamination curtains support negative-pressure environments?

They can support negative-pressure rooms when paired with proper ventilation systems, helping isolate contaminated areas more effectively.

How long do industrial decontamination curtains last?

With proper cleaning and maintenance, decontamination curtains typically last 3–7 years depending on usage, chemical exposure, and environmental conditions.

Can these curtains divide large washdown areas into multiple zones?

Yes, modular curtain layouts allow facilities to create multiple decontamination zones, improving workflow, safety, and contamination control.

Curtain Track

- 16 gauge galvanized steel tracks

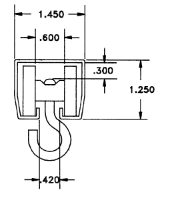

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

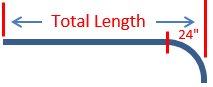

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.