OVERVIEW

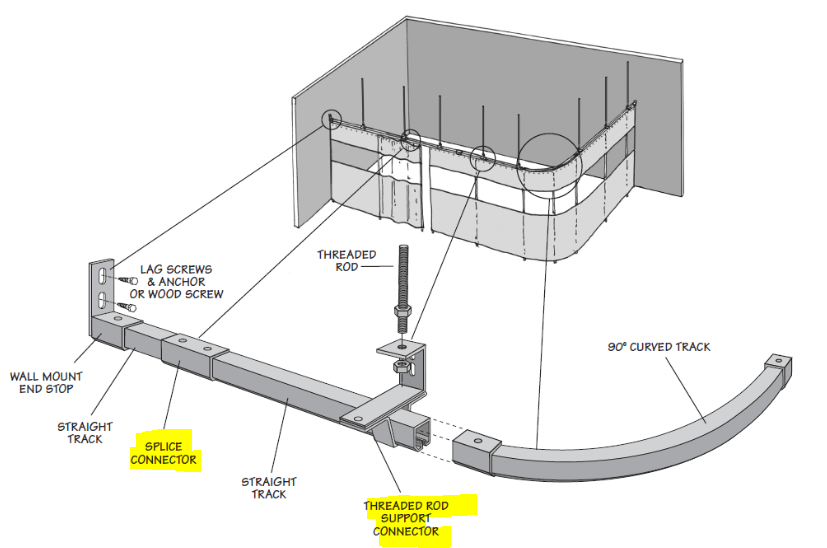

Industrial Curtain Track with roller hooks allows you to roll the industrial curtain side to side which allows maximum access to both sides of your work area. The heavy duty curtain track is modular in design in that it comes in 2,3,4,5,6, 8 and 10’ lengths that easily bolt together.

Made For Industrial Use

Industrial Curtain Track

Akon can supply several different types of industrial curtain track mounts to hang your curtain (See Below). These tracks are made from strong 16 gauge galvanized steel or stainless steel for USDA Curtains. The heavy duty curtain tracks come in 2,3,4,5,6,8 and 10 foot lengths which splice together to form any length. This track utilizes radius corners to form enclosures or floor plates to be free-standing.

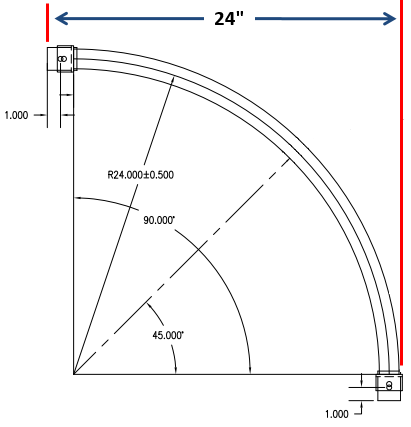

Curtain Track Corners

Almost any configuration is possible with the use of the 90-degree radius corners. These 24” radius corners allow the curtain to roll from one side to the other with ease. Hard 90 degree corners are also available.

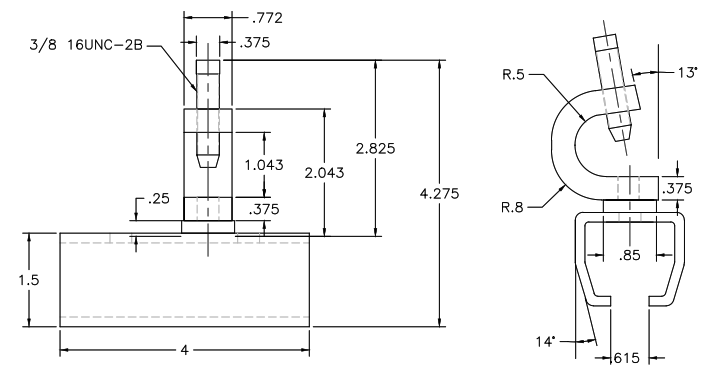

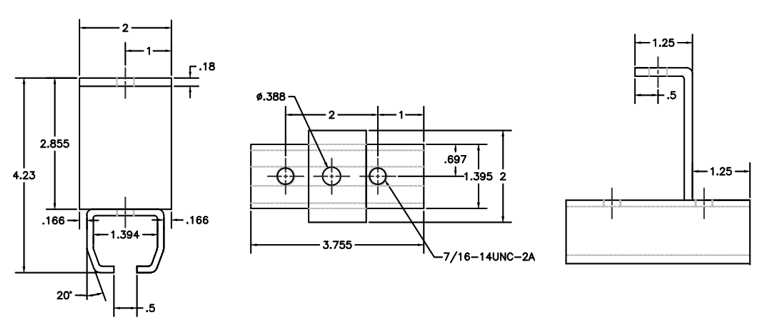

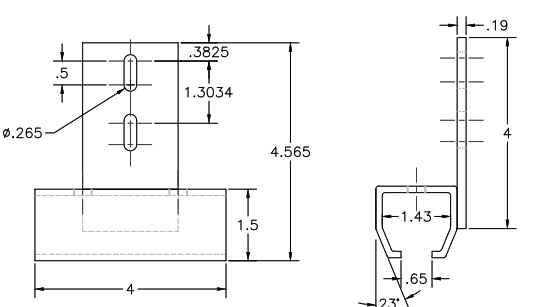

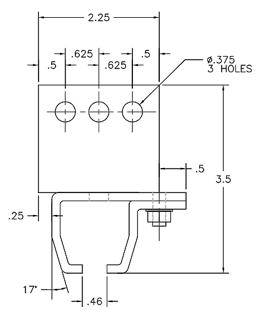

Curtain Track Supports

Depending on your needs, you can choose from many different track supports. The track supports are what holds the curtain track up. These supports clamp/bolt onto the straight track and are spaced about every 5’ to 8’ depending on your industrial curtain weight. See the different styles below.

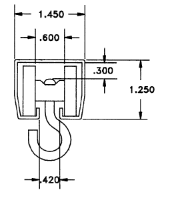

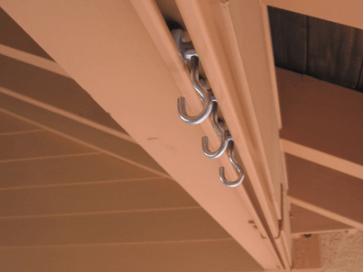

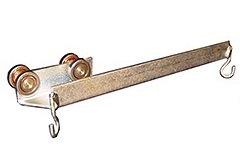

Industrial Curtain Hooks

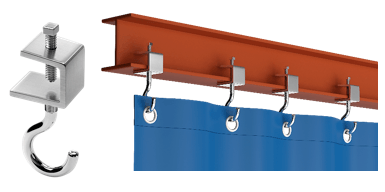

The roller hooks allow the curtain to easily roll from side-to-side with minimal friction. These industrial curtain hooks come in two styles which are Nylon or Steel wheels with ball bearings. Nylon Rollers have a 40lb capacity while the steel rollers have a 75lb capacity. The steel wheels are utilized for very heavy curtains. They are spaced every 12” in the track.

Curtain Track Mounts

Ceiling Mount

This mounting style works best when you want to mount the industrial curtain directly to your ceiling.

Wall Mount

This industrial curtain track mount style is ideal when the curtain will attach to a vertical surface, such as a wall or wooden trusses.

Chain or Cable Mount

This mounting style works best when the curtain will hang down from a tall ceiling or when you need to get below obstructions.

Threaded Rod Mount

Like the chain or cable mounts, the threaded rod can be used to hang below obstructions or to drop down from tall ceilings. Note: Anchors for all-thread rods can be found here.

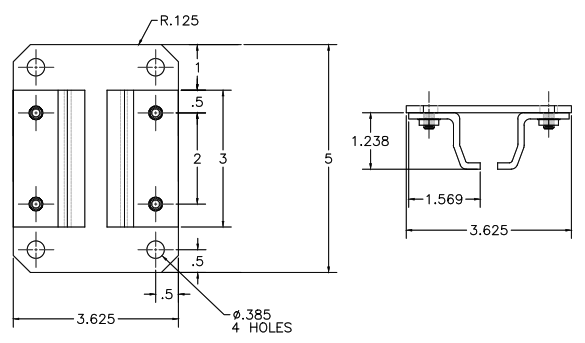

I-Beam Mount

This mounting style works best when attaching to I-Beams or the trusses of the roof. Set screws are used to clamp down the mount.

Static Mounts

Aluminum Angle

Aluminum angle and Tek screws hold the curtain up. The angle is clamped to the joists or anchored into the roof deck. Then self taping Tek screws are screwed into the angle through the curtain grommets with a washer to pinch the curtain to the angle.

Side-to-side movement: NO

I-Beam Clamps

The I-Beam clamps allows for mounting to any flange such as joists, purlins, and of course I-Beams. The eye hook then goes through the grommets and into the bottom of the clamp.

Side-to-side movement: NO

Mounting Ideas (Not Supplied by AKON)

Tension Cables

You can hang your curtain using aircraft cable, S-hooks, and cable turnbuckles to tighten the cable. The S-hooks go through the curtain grommets. Not supplied by AKON but readily available from most hardware stores and online stores.

Side-to-side movement: YES

Magnetic Curtain Hooks

Magnetic curtain hangers can support 65lbs for each hook. They are a versatile option for hanging curtains that don't require any drilling. They also allow you to quickly take them down when not needed. You would only need a few of these to support a long stretch of curtain. Not supplied by AKON but readily available from most hardware stores and online stores.

Side-to-side movement: NO

Photo Gallery

Frequently Asked Questions

Hanging industrial curtains properly depends entirely on having the right track system. The hardware needs to handle heavy curtain weight while still allowing smooth movement when workers need to open or close sections. Different facilities have different ceiling structures, which means the mounting method that works in one warehouse might not fit another. This FAQ breaks down the various track options, mounting styles, and hardware components so facilities can choose what actually works for their specific setup.

Industrial Curtain Track Hardware – Frequently Asked Questions

What is industrial curtain track hardware?

Industrial curtain track hardware is the system that supports and allows movement of heavy-duty industrial curtains. It includes tracks, rollers, trolleys, and mounting brackets designed for smooth operation in factories, warehouses, and commercial facilities.

What materials are used for the track components?

Tracks are typically made of galvanized steel or aluminum for durability and rust resistance. These materials withstand heavy use, humidity, and temperature changes while maintaining structural integrity for years of operation.

Can I install industrial curtain tracks on the ceiling?

Yes. Ceiling-mounted track systems are commonly used when floor space is limited. They allow curtains to slide overhead, creating clean separation between areas without blocking floor operations.

Do you offer wall-mounted track options?

Yes, wall-mounted track hardware is available. It’s ideal for situations where ceiling installation isn’t possible or when side mounting offers better alignment with your space layout or machinery height.

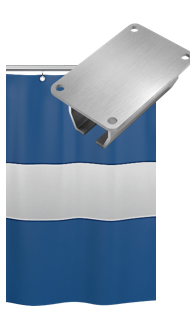

What curtain types are compatible with your track hardware?

Our track hardware works with a wide range of industrial curtains, including warehouse dividers, welding screens, soundproof curtains, and temperature control panels. Each system can be configured to fit your specific curtain type and weight.

How much weight can industrial track hardware hold?

Each track system is rated for a specific load capacity, typically supporting 100–400 pounds per linear run. The exact rating depends on the track size, trolley spacing, and mounting method used.

Can I cut the track to fit my custom dimensions?

Yes. Tracks can be easily cut on-site using a metal saw to achieve precise dimensions. Always measure twice before cutting and smooth any sharp edges for safe installation.

Do you provide curved or angled track sections?

Yes. Curved track sections and 90-degree corners are available for layouts that require turns or angled partitions. These options allow for flexible configurations and efficient space division.

What mounting hardware is included?

Standard mounting kits include brackets, trolleys, and end stops. Additional accessories like splicers, hangers, and clamps can be ordered separately depending on the type of installation.

Is the track hardware suitable for outdoor use?

Yes, when galvanized or powder-coated. Outdoor-rated track systems resist rust, moisture, and UV exposure, making them suitable for loading docks, exterior enclosures, or outdoor work areas.

How do the rollers or trolleys work?

Trolleys glide inside the track using ball-bearing or nylon wheels. They ensure smooth curtain movement with minimal friction, even under heavy loads, and are built for long-term industrial use.

Can one track support multiple curtains?

Yes. A single track can support multiple curtains using separate sets of trolleys and hooks. This setup is ideal for flexible layouts where sections need to move independently or overlap.

Are replacement parts available?

Yes. Replacement rollers, trolleys, and brackets can be purchased individually. This allows you to repair or upgrade sections of your curtain track system without replacing the entire setup.

What is the typical lifespan of the hardware?

When properly installed and maintained, industrial curtain hardware can last over a decade. Routine cleaning and occasional lubrication of moving parts can extend its lifespan significantly.

Can the track system be moved or reconfigured later?

Yes. The modular design allows tracks to be relocated or extended easily. This flexibility makes it a cost-effective option for facilities that regularly change layouts or workflows.

Do you provide installation guides?

Yes. Every order includes a detailed installation guide with diagrams and step-by-step instructions. Technical support is also available to help with planning or troubleshooting your setup.

Can I combine straight and curved tracks in one system?

Absolutely. Straight and curved track sections can be joined seamlessly using track splicers. This allows your curtain to travel smoothly through corners and complex pathways.

Are the components compatible with other brands?

In most cases, yes. Our hardware uses standard track dimensions compatible with many other industrial curtain systems, though we recommend checking measurements before mixing components.

What maintenance does curtain track hardware require?

Minimal maintenance is needed. Keep the track clean and occasionally apply a light lubricant to trolley wheels. Regular inspection ensures smooth operation and prevents wear over time.

Do you offer custom track lengths and configurations?

Yes. Custom lengths and layouts can be manufactured to match your facility’s requirements. Provide your dimensions, and we’ll tailor the hardware for a perfect fit and easy installation.

Construction

The curtain tracks are constructed from galvanized steel that is used both indoors and outdoors. Unlike most curtain track hardware which is lightweight and made for light duty use, our industrial curtain track hardware is heavy duty and made to last. These tracks are made for industrial abuse. The steel curtain track is 16 gauge thickness. (Note 16 gauge = 0.0635 inches).