Overview

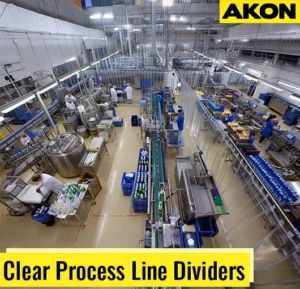

Walk into most warehouses or manufacturing plants, and there's a good chance everything is happening in one massive open space. Different production lines run side by side, workers move between areas freely, and various processes share the same air and environment. On the surface, this seems efficient. The reality tells a different story. When process lines remain undivided, problems start stacking up fast.

The Hidden Costs of Undivided Spaces

Why open spaces can quietly drain productivity

Open warehouse spaces seem like the efficient choice. Everything stays visible, workers move freely, and there's no construction involved. But when different processes share the same air, temperature, and environment, it could cause issues in the long run.

Temperature control becomes expensive when one area needs cooling while another generates heat. Cross-contamination happens when dust or fumes from one line drift to another. Noise from multiple machines makes communication difficult and wears down workers. When inspection places aren't kept clear of debris, quality control is harmed. These problems can cause food preparation plants to break health rules and have to close.

The good news? There are a number of useful ways to separate process lines. The best one for each facility relies on its needs and budget.

How to Divide Process Lines in Your Facility

Permanent Wall Construction

Building permanent walls is the most traditional approach. Drywall, concrete blocks, or metal panels create solid barriers between processes. These walls provide excellent sound insulation, complete visual privacy, and the strongest temperature separation.

Permanent walls last for decades with minimal maintenance. They offer the best noise reduction, which matters in facilities with extremely loud equipment. Fire-rated walls add safety benefits. Climate control becomes much easier when zones are completely sealed off from each other.

However, permanent construction comes with significant drawbacks. The upfront cost runs high, expect to spend thousands of dollars per section, not counting permits and downtime during installation. Once built, these walls are permanent and can't be moved in case your facility needs re-arrangements. Permanent walls also block natural light and make observation challenging since managers can't see what's happening in other zones without walking into the area itself.

Modular Panel Systems

Modular panels sit somewhere between permanent walls and curtains. These rigid sections snap or bolt together, creating dividers that feel solid but can still be reconfigured. Most use aluminum frames with different insert options, solid panels, clear windows, or ventilated sections. Installation goes faster than traditional construction, and when layouts need adjusting, the panels come apart and can be re-assembled elsewhere. They handle temperature separation decently and cut noise pretty well. The professional appearance works great in areas where clients visit.

But here's the catch: they cost more than curtains and take up storage space when not in use. Moving them around requires real effort compared to rolling up vinyl. Facilities that stick with one layout for years get good value. Operations that shuffle things around quarterly will find the rigidity quite uncomfortable.

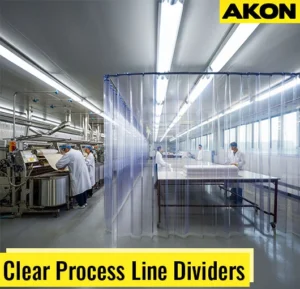

Clear Vinyl Divider Curtains

AKON's Clear vinyl dividers are an excellent choice for dividing process lines. These strong, transparent curtains can be installed easily and let you set up clear work zones without building permanent walls. You get the benefit of seeing what’s happening on both sides while still keeping dust, noise, or unwanted cross-traffic from interfering with each process line.

They’re faster and more cost-effective than constructing walls, and great for adjusting as your production changes. Because they’re made from industrial-grade vinyl, they stand up to wear, tear and shifting layouts. If you want to separate one line from another while keeping visibility and flexibility, these dividers work really well.

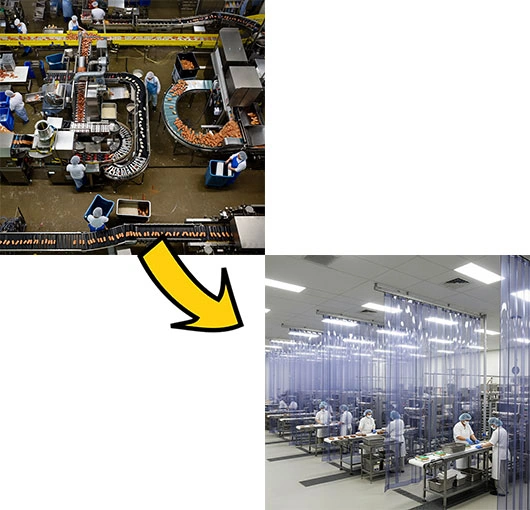

USDA-Approved Divider Curtains

Food processing operations face requirements that standard dividers can't meet. AKON's USDA-approved Washdown Curtains are specifically designed to handle the demands of food safety regulations.

These specialized curtains resist mold and bacterial growth even in wet environments. They're built to withstand high-pressure washing during daily sanitation. The material doesn't deteriorate when exposed to cleaning chemicals repeatedly.

Standard curtains might seem cheaper initially, but they'll fail inspections. The cost of violations, shutdowns, and damaged reputation far exceeds the price difference between standard and food-grade dividers. For any facility handling consumable products, the certified option is really the only option.

Freestanding Divider Systems

Not every building has ceiling structures that can support hanging dividers. Some warehouses have ceilings so high that mounting anything becomes impractical.

AKON's Freestanding Divider Systems solve these problems with portable frames that don't require overhead mounting. The frames stand on their own and can be positioned wherever separation is needed.

This portability is valuable for facilities with changing layouts. Temporary projects get the division they need without permanent installation. Increased production demand during holidays can be accommodated by bringing in additional freestanding units.

These curtains are durable, cost-effective, and quick to set up which makes them a perfect fit for companies that are looking for a quick and effective solution.

Comparing All Your Options

Figuring out how to separate work areas really comes down to how a facility is set up and what kind of cleanliness standards need to be met. Some places have to be super strict about hygiene and keeping temperatures consistent, while others just need something more flexible that can move around when needed. Below is a quick rundown of the different divider options people typically use in production spaces, from those clear plastic curtains to full permanent walls. Each one has its pros and cons when it comes to how much you can see through it, what it costs, and how hard it is to install. The goal is finding what works for the situation without breaking the bank or making things harder than they need to be.

| Solution | Description | Cost | Installation | Visibility | Lifespan | Best For |

|---|---|---|---|---|---|---|

| 🔹 Clear Vinyl Curtains | Transparent vinyl dividers that keep process lines separate while allowing full visibility. Ideal for dust control, temperature management, and easy communication between zones. | $$ | Easy to Moderate 🔧 | 🌈 Excellent – fully clear | 5–10 years | General manufacturing, food packaging, and clean zones |

| 🥼 USDA-Approved Divider Curtains | Wash-down vinyl curtains designed for food and pharmaceutical production. Easy to sanitize and resistant to moisture, mold, and bacteria buildup. | $$$ | Moderate 🪚 | 🌤️ Partial – available in clear or solid colors | 8–12 years | Food processing, USDA-regulated facilities |

| 🏗️ Modular Cleanroom Panels | Prefabricated wall systems that create sealed and sterile environments. Provide structure and contamination control while maintaining modular flexibility. | $$$$ | Professional 👷♂️ | 🔳 Moderate – can include clear sections | 10–20 years | Pharma, electronics, and precision manufacturing |

| 🧱 Permanent Walls | Fixed structures made of concrete, drywall, or polycarbonate. Offer maximum durability and sound isolation but require more time and cost to install. | $$$$–$$$$$ | Professional 🧰 | 🚫 Limited – opaque unless polycarbonate | 15–25 years | Long-term facility layouts and high-security areas |

| 🚧 Freestanding Divider Curtains | Portable vinyl or fabric dividers mounted on frames. Easily repositioned to adjust to workflow changes or isolate temporary processes. | $–$$ | Very Easy 🪛 | 🌤️ Partial – available in clear or opaque | 3–7 years | Temporary work zones and flexible production layouts |

The Best Solution: Vinyl Curtain Dividers

A Flexible and Cost-Effective Solution

AKON Vinyl Curtain Dividers are probably one of the easiest and cheapest ways to split up different areas in a factory or warehouse. They give you that separation between spaces without having to build actual walls, which saves a ton of time and money. The material is flexible enough that workers can move through pretty easily, but it still does a solid job keeping out dust, cutting down noise, and stopping temperatures from mixing between zones. It also helps prevent contamination from spreading.

What's nice is they're simple to wipe down and swap out when needed, so they work really well for places that need to rearrange things often or stay on top of cleaning. You can still see through them too, which makes it easier for people to communicate and stay aware of what's happening around them. All in all, vinyl curtains hit that sweet spot where you get flexibility and toughness without spending too much.

Easy Install

Industrial curtains come with grommets at the top making hanging the curtains quick and easy with or without the curtain track.

Inexpensive

Industrial curtains are about 1/3rd of the cost of other separation methods such as rigid walls or panel systems and are easy to store.

Separate Workers

Industrial curtain walls are ideal for separating workers for welding, washing, packaging and many other operations.

Control Noise

Industrial curtains help reduce noise due to the thick PVC they are made from which makes for a more comfortable work environment.

Material Options

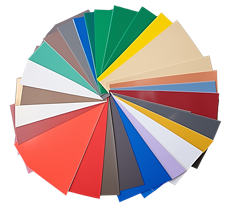

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Frequently Asked Questions

Picking the right divider for your work areas can really impact how smoothly things run day to day. Some facilities need clear vinyl curtains so everyone can see what's going on, others require heavy-duty washable dividers that meet food safety standards, and some just want movable panels they can shift around as needed. Vinyl options tend to be pretty practical and won't eat up the budget like permanent structures might. Below are some of the questions that come up most often about these divider systems. They cover things like how to install them, what kind of upkeep they need, whether you can customize them, and how well they hold up in different types of industrial environments.

Process Line Dividers Using Vinyl Solutions – FAQ

What are process line dividers?

Process line dividers are barriers used in industrial facilities to separate different work zones. They help control temperature, noise, and contamination, creating safer and more efficient production areas without permanent walls.

How do vinyl curtains work as process dividers?

Vinyl curtains hang from tracks or frames to form flexible partitions. They create clear or solid separations between work zones, helping manage airflow, hygiene, and workflow without construction or downtime.

Can I use vinyl curtains in food processing areas?

Yes. Clear or USDA-approved vinyl curtains are perfect for food facilities. They resist moisture and bacteria, maintain visibility, and meet health and safety standards for regulated environments.

Why choose vinyl dividers over permanent walls?

Vinyl dividers are faster, cheaper, and easier to install than permanent walls. They can be reconfigured anytime as layouts change, offering flexibility while still providing strong separation and containment.

What are USDA-approved vinyl curtains?

USDA-approved vinyl curtains are made from materials that resist bacteria, mold, and moisture. They can be cleaned or sanitized easily and meet strict USDA and FDA hygiene requirements for processing facilities.

What are modular cleanroom panels?

Modular cleanroom panels are rigid wall systems designed for sterile environments. They provide complete containment for sensitive operations but are more expensive and less flexible than vinyl divider solutions.

What are freestanding vinyl dividers?

Freestanding vinyl dividers are portable partitions mounted on metal frames. They allow quick setup and repositioning, ideal for temporary zones, seasonal use, or evolving production layouts.

Do vinyl dividers help control temperature?

Yes. Vinyl curtains help regulate temperature by separating hot and cold areas. This reduces strain on HVAC systems and maintains consistent conditions across different production zones.

Can vinyl curtains reduce noise between process lines?

Yes. Heavy-duty vinyl absorbs sound and reduces noise levels from machinery. This helps improve communication and comfort for workers in busy production spaces.

How long do vinyl divider curtains last?

High-quality vinyl dividers typically last between 7 and 10 years. With regular cleaning and proper care, they can remain effective much longer, even in demanding environments.

Are vinyl dividers easy to clean?

Yes. Vinyl dividers are easy to wipe down with soap and water. Wash-down models can be sanitized frequently without damage, making them ideal for hygienic or food-related industries.

Can vinyl dividers be customized?

Yes. Vinyl curtains can be made in custom sizes, colors, and configurations. You can add clear panels, doors, or reinforcement to fit your exact facility layout.

How are vinyl dividers installed?

Vinyl curtains can be installed on ceiling-mounted tracks, wall brackets, or freestanding frames. Most setups are quick and can be done with basic tools, minimizing downtime.

Can vinyl dividers handle moisture or chemicals?

Yes. Industrial-grade vinyl is resistant to water, grease, and most cleaning chemicals. This makes it ideal for wash-down and high-moisture areas in food or manufacturing facilities.

Can I move or reconfigure vinyl dividers?

Yes. Vinyl divider systems are designed to be flexible. You can slide, remove, or reposition panels anytime to accommodate new workflows or layout changes.

Are vinyl dividers safe to use near machinery?

Yes. Vinyl dividers clearly define work zones, reducing the risk of accidents. They also help contain dust and debris from cutting, grinding, or welding areas.

How do vinyl dividers compare to modular panels?

Vinyl dividers are more flexible and cost-effective, while modular panels offer permanent, sealed containment. Vinyl works best for general manufacturing; panels suit cleanroom or high-precision operations.

Can I install vinyl dividers myself?

Yes. Most vinyl divider systems are designed for simple installation. Many customers install them in just a few hours without professional help, using only basic tools.

Do vinyl dividers meet safety and hygiene standards?

Yes. Many vinyl materials meet USDA, FDA, and NFPA standards for hygiene and fire safety. Always confirm certification before purchase for your specific industry.

Where can I order vinyl process line dividers?

You can order vinyl divider curtains directly from Curtain-and-Divider.com. Choose from clear vinyl, wash-down, or freestanding options to fit your process line needs.

Summary

Every facility has different needs, but three solutions handle most situations really well. Clear vinyl divider curtains work great when visibility matters. They can be installed quickly, cost way less than building walls, and move around when the layout needs to change.

Food processing facilities have stricter rules, so USDA-approved washdown curtains are the best solution for them. They stand up to daily power washing and meet all the health department requirements. Some facilities have ceilings too high for hanging anything, or maybe the layout changes all the time. Freestanding divider systems solve that problem because they stand on their own and roll wherever they're needed. These three options fix real problems without spending forever on construction or getting stuck with something permanent.

Ready to get started? Contact AKON today and let us give you solutions that will actually work!