OVERVIEW

Akon can supply you with ESD Curtains. These Antistatic Curtains are critical for applications where any electrical discharge could pose an explosion risk or damage critical components. Unlike topically treated antistatic materials which can wear off after prolonged use, our line of industrial curtains is completely antistatic. The ESD PVC film has an anti-static agent added at the compound stage making it last longer. Also available are ESD grid curtains.

Easy Install

Antistatic curtains come with grommets at the top making hanging the curtains quick and easy with or without the curtain track.

Inexpensive

Antistatic curtains are about 1/3rd of the cost of other separation methods such as rigid walls or panel systems and are easy to store.

Separate Workers

Antistatic curtain walls are ideal for separating workers from sensitive areas where electrical discharge could be dangerous.

Control Noise

Antistatic curtains help reduce noise due to the thick PVC they are made from which makes for a more comfortable work environment.

Common Applications

The appearance of these antistatic curtains is the same as any common PVC film. Both sides of the film have the same properties. These curtains are commonly used in the following applications. The Industrial ESD PVC curtains also have a great draping ability so that they can be used as protective covering for carts, instruments, or even entire walls.

- Cleanroom ESD Curtains

- Semiconductor ESD Curtains

- Microelectronics ESD Curtains

- Production processes sensitive to electricity

Material Options

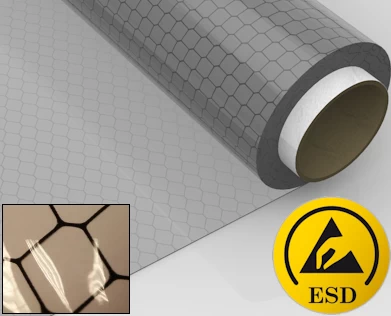

ESD Grid Curtain / Antistatic Curtain Film

These curtains are an ideal barrier curtain wall for sensitive environments. The honeycomb grids are installed on both sides of the PVC curtain for additional dissipation of static electricity. The material is 12mil thick.

- Material is thin which compacts easily

- The PVC grid curtains are less expensive than thicker materials

- The PVC can ship in rolls that are quick to deploy

- The conductive scrim grounds the static charges

ESD Strip Curtains and Doors

Strip curtains allow the rapid movement of people and material from one side to the other. The strips come in widths of 4” up to 12” depending on your application needs.

- ESD Strips come in thickness from .080” to .240”

- Mounting hardware comes in stainless or galvanized

- Strips can be purchased in bulk rolls or pre-cut and punched

- They are easy to replace should they become damaged

ESD PVC Curtain Walls

Like the anti-static grid curtain shown above, the curtain walls are generally thicker and more robust. They come in thicknesses from 14 mil to 120 mil. These can be installed as static fixed in place barriers or movable side-to-side walls via industrial track.

- Can be hundreds of feet wide to section off large spaces

- Sections can be Velcro or magnet attached

- PVC comes in all clear, tinted, solid color, or frosted

- The curtains can be secured to the floor for a clean finish

- 14 Mil Film, 40 Mil (1.0mm), 60 Mil (1.5mm), 80 Mil (2.0mm), 120 Mil (3.0mm)

ESD Vinyl Curtain Walls

Less expensive than the thicker ESD PVC curtain material above, the ESD Vinyl curtains are thinner and more flexible. They are custom made to your specific requirements just like the other materials.

- Light forest green front and black back

- Can be double layered for black front and back or green front and back

- Static dissipative green front and conductive black back

- Surface resistance on the green side of 109 – 1010 ohms

AKON Antistatic Curtains Used By

Frequently Asked Questions

Electronics manufacturing and semiconductor facilities risk destroying sensitive components worth thousands when static electricity discharges. Regular curtains generate static through friction and make things worse instead of helping. ESD curtains have antistatic properties built into the material rather than sprayed on coatings that wear off quickly. The material dissipates static charges safely instead of letting buildup arc to equipment. Cleanrooms and production areas use these to separate static controlled zones from regular work spaces. This FAQ covers the difference between dissipative and conductive ratings, whether antistatic properties actually last, how often cleaning is needed, and if outgassing versions smell bad enough to cause complaints from workers on the floor.

ESD Curtains | Antistatic Curtains – Frequently Asked Questions

What are ESD curtains used for?

ESD curtains are used to control electrostatic discharge in sensitive environments such as electronics assembly, packaging, laboratories and cleanrooms. They help prevent static buildup and protect components, equipment and personnel from ESD damage.

How do antistatic curtains prevent static discharge?

Antistatic curtains contain conductive or static-dissipative materials that safely neutralize electric charges before they accumulate. This reduces the risk of sparks, shocks and component failure caused by static discharge.

What materials are ESD curtains made from?

They are typically made from PVC, vinyl or polyurethane films infused with carbon or other conductive agents. These materials are specifically engineered to maintain low surface resistivity for static control.

Are ESD curtains safe for electronics and cleanrooms?

Yes. ESD curtains are designed to meet static-dissipative requirements while maintaining cleanliness, low particle generation and compatibility with electronics manufacturing and laboratory environments.

Do ESD curtains meet industry standards?

Yes. Many products comply with ANSI/ESD S20.20, IEC static control standards and cleanroom requirements depending on the selected material and environment category.

Can ESD curtains be customized for specific work areas?

Yes. Custom sizes, mounting styles, thicknesses, grounding hardware, vision panels and modular layouts are available to fit workstations, equipment bays or cleanroom openings.

How are ESD curtains grounded?

They can be connected to a grounding point using snaps, straps or grounding wires integrated into the curtain system. Proper grounding ensures safe dissipation of electric charge.

Do ESD curtains reduce dust or contamination?

Yes. The curtain material acts as a physical barrier that helps isolate areas and reduce the movement of dust, particles and contaminants while still allowing visibility and access.

Can ESD curtains be used with existing partitions or enclosures?

Yes. They integrate easily with modular wall systems, strip curtains, cleanroom dividers and workstation barriers to enhance static protection across the workspace.

Are transparent or tinted ESD curtains available?

Yes. ESD curtains come in clear, tinted or semi-transparent options to provide visibility while still offering static protection and controlled light transmission.

Can ESD curtains be installed on tracks or sliding systems?

Yes. They are compatible with ceiling tracks, rolling hardware, strip-style mounts and stationary frames, providing flexible access and layout options.

Do ESD curtains help improve workplace safety?

Yes. By reducing static discharge, they help prevent component damage, equipment malfunction and worker shock risks in sensitive environments.

Are antistatic curtains durable?

Yes. The materials are engineered to withstand repeated use, chemical exposure and environmental changes while maintaining consistent static-dissipative performance.

Can ESD curtains be cleaned easily?

Yes. They can be cleaned with mild cleaners approved for electronics areas. Regular cleaning helps maintain antistatic performance and transparency.

Do ESD curtains come in modular panels?

Yes. Modular panel systems allow you to expand, reconfigure or replace sections without removing the entire curtain assembly.

Do antistatic curtains block airflow?

They can restrict airflow depending on thickness, but do not fully seal the area. They help define zones while still allowing some air movement.

Are ESD curtains suitable for humidity-controlled environments?

Yes. Antistatic materials are designed to maintain static-dissipative properties even in dry, low-humidity conditions where static buildup is more likely.

Can ESD curtains be used around machinery?

Yes. They help protect equipment from static discharge and create visual barriers around sensitive machinery while allowing operators to maintain clear visibility.

How long do ESD curtains last?

With proper maintenance, grounding and cleaning, ESD curtains maintain performance for many years, even in demanding industrial environments.

What advantages do ESD curtains have over standard vinyl curtains?

ESD curtains offer controlled surface resistivity, static protection, enhanced safety and compatibility with electronics or cleanrooms—features standard vinyl curtains cannot provide.

Common Questions

What's the difference between ESD Anti-Static vs Anti-Static Coated?

- ESD - Has anti-static proprieties that are part of the PVC and can never wear off. (Most Expensive, Longest Lasting and Highest possible Anti-Static Properties). ESD comes in 2 styles which are Outgassing and Non-Outgassing.

- Anti-Static Coated - Has a sprayed on Anti-Static Coating which with enough time and friction might wear off. (Least Expensive)

What is surface resistance?

- Surface resistance is a measurement of how easily an electric charge can travel across a medium. Conductive materials are those that have a surface resistance of less than 1 x 105 ohms/square. Dissipative items have a surface resistance of more than 1 x 105, but less than 1 x 1011 ohms square.

- Antistatic materials are generally referred to as any material which inhibits triboelectric charging. This kind of charging is the buildup of an electric charge by rubbing or contact with another material.

- An insulative material is one that has a surface resistance of greater than 1 x 1012 ohms square

Does AKON offer spray-on ESD inhibitors?

- No. Spray-on inhibitors wear off in a short time. The ESD-resistance properties in ESD materials are part of the formulation of the vinyl. That means the ESD-resistant properties are permanent. They do not wear off.

ESD Outgassing Vs Non-Outgassing?

- Outgassing - Anti-static properties are built in not sprayed on so the curtains will need to be cleaned periodically as the anti-static properties that are attached to the plasticizers migrate to the surface. This will not degrade the material as you can't wipe away the anti-static properties as they are part of the polymer. This happens with all ESD curtains on the market. There is also an aroma to the curtains. Cleaning it periodically is highly recommended – every 3-6 months depending on the environment.

- Non-Outgassing - This material which is also called thermoplastic polyurethane is inherently anti-static and is a true non-outgassing esd anti-static curtain. However, the non-outgassing esd curtains are more expensive. Since this material does not outgas the smell would also be considered neutral.

Can ESD curtains be used outdoors?

-

- No. they are not ideal for outdoor use: The sun causes the anti-static properties to bloom and migrate to the surface making the strips greasy and cloudy

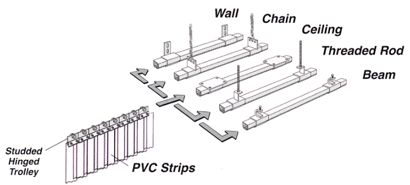

Solid Curtain Hardware

Static Mount

Rolling Hardware

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.

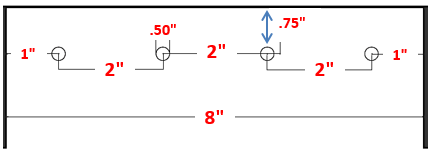

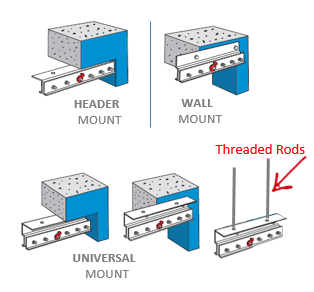

Strip Curtain Hardware

Static Mount

- Header Mount

- Wall Mount

- Universal Mount

- Threaded Rod Mount (Just a Feature of Universal Mount)

Free-Standing Mount

- Supported from the floor up

- Used in open floors when you can support from above

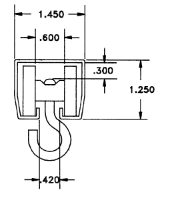

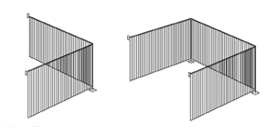

Rolling Hardware

- Allow the strips to roll out of the way

- Ideal for complete access when strips are not needed

- Note the strips roll like a barn door and do not fold up