Description

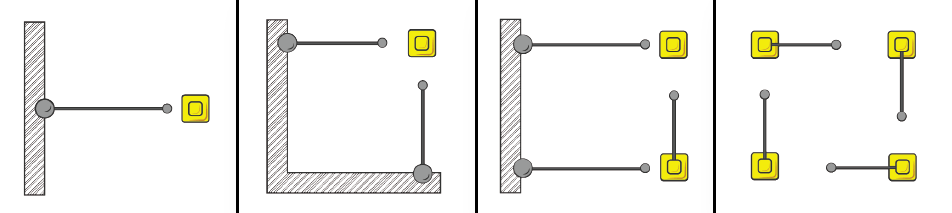

Possible Layouts

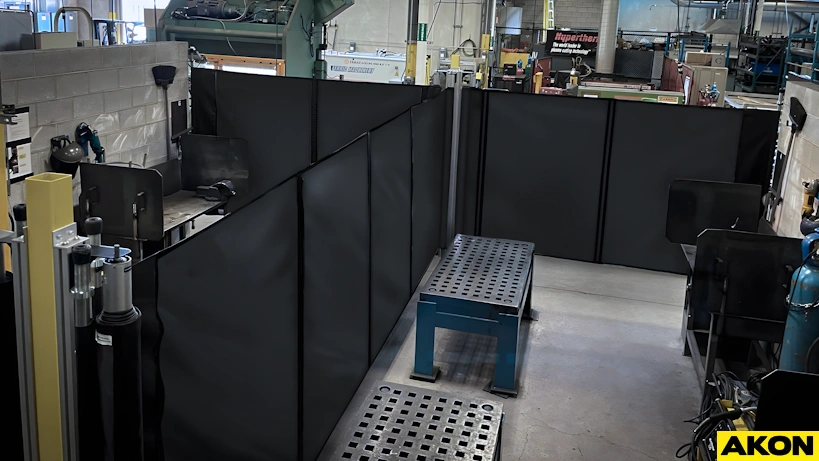

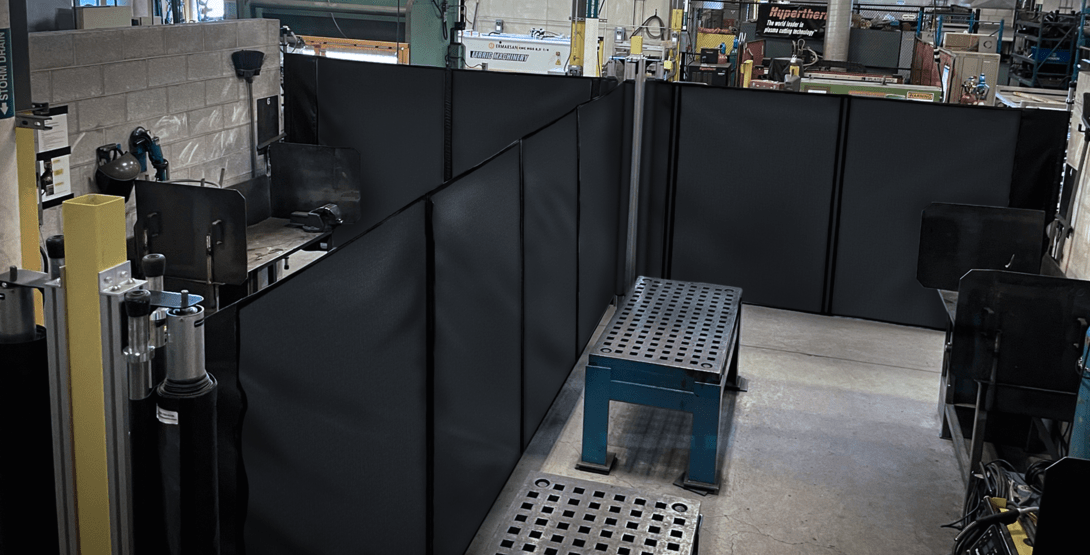

Overview

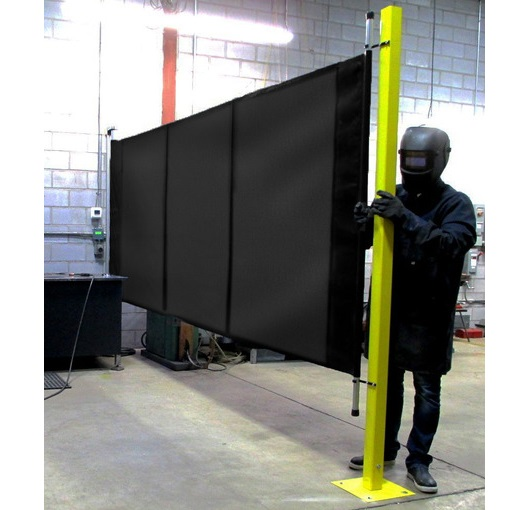

The SB-9000L Retractable Welding Laser Screen is designed with a retractable system that extends up to 20 feet long and automatically retracts with a spring tension roller. The retractable welding laser barrier screens use a simple J-hook attachment opposite the roller, making it easy to replace the laser barrier shade if it becomes damaged. With their durable construction and versatile design, the retractable welding barrier screens offer a reliable solution for laser areas requiring protection.

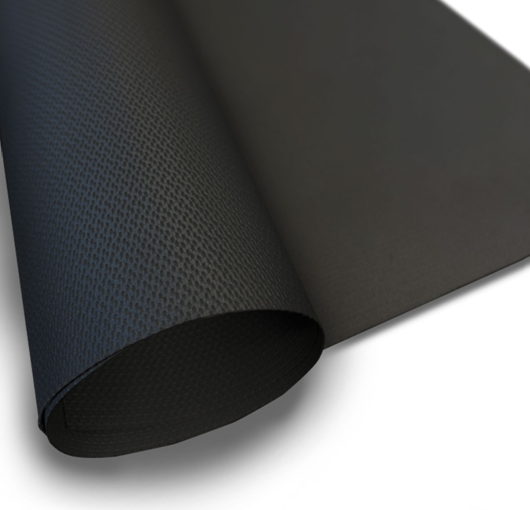

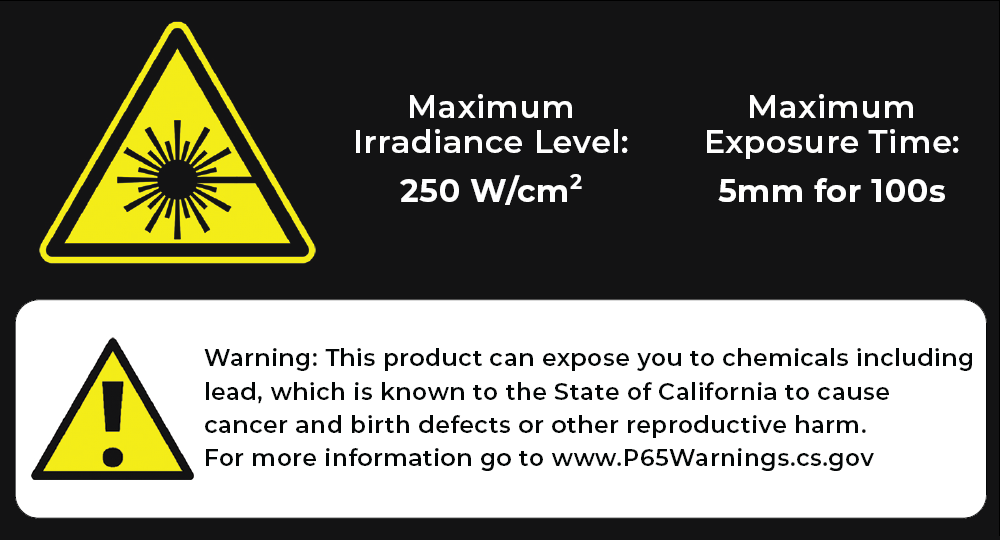

Shade

- The laser barrier shade provides optimal protection with a max irradiance of 250W/cm2 and protection against diffusion beams, ensuring the safety of the operator and the work environment.

- The material is designed specifically for the IPG LightWeld product, ensuring maximum compatibility and effectiveness.

- Testing completed is EN12254

Retractable Welding Laser Screens

- Eliminates the effort of man-handling large sections of stationary guards

- Conserves floor space

- The retractable laser screen will extend up to 15 feet in length

- The laser shade can be easily replaced if damaged

Easy Operation

- The laser screen uses tension from the roller base to keep the guard tight.

- The operator simply walks the guard from side to side in the work area.

- When it is time to move people or products into or out of the area, the operator unlatches the guard and walks it back to the roller base.

- A minimal pull force is required to extend the retractable laser barriers

Innovative Design

- The spring tension roller is always taunt and automatically retracts

- When not in use, the shade stores neatly rolled up

- The commercial laser screen attaches with a simple S-hook opposite the roller

Lead Time | Warranty

- Free Shipping!

- Ships in 7-10 work days

- Ships UPS or FedEx. You can also specify your shipping account

- 5 year warranty on manufacturing defects

Are the laser shades replaceable?

Yes the laser shades are replaceable should they become damaged. You would simply contact AKON and we would provide you with directions and the replacement shade.

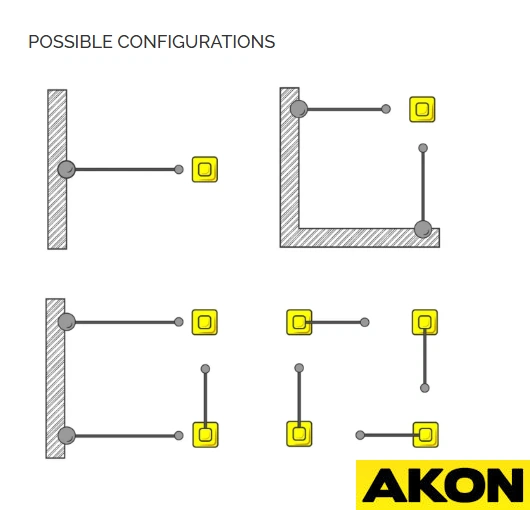

How do the shades attach to the opposing posts or wall?

They utilize a simple J-hook design. Each shade has an aluminum bar that is held in place by two J-Hooks using the tension force of the shade. These are attached to an adjacent post or you can attach them to any existing structure you currently have such as a vertical wall or steel columns.

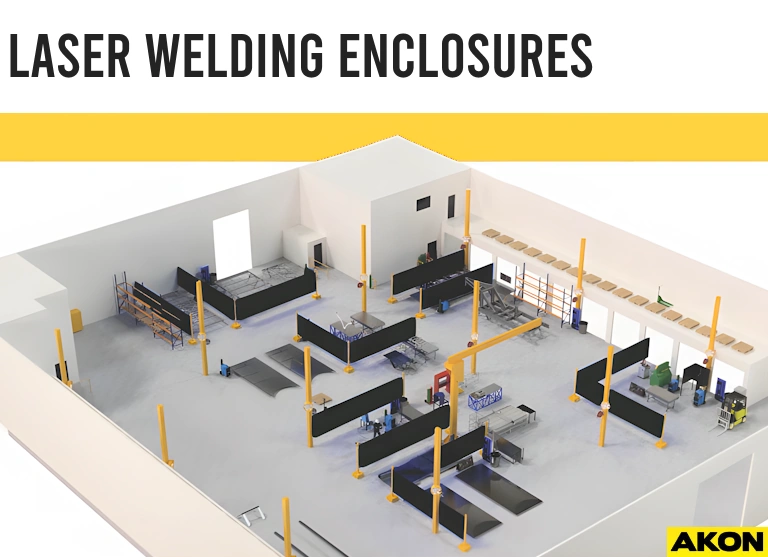

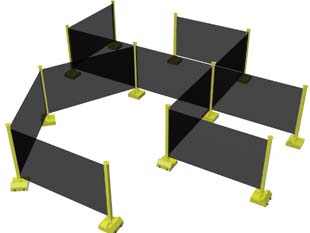

Can we make any shape?

The unique benefit of this type of laser screen system is that almost any shape can be designed. You can form long, straight laser walls, or you can form multiple laser cells. It allows for flexibility in commercial and manufacturing facilities for both personnel and robotic laser operations.

What if I want the posts to be portable?

If you want the ability to move the posts around, then the shade can be mounted to a portable post that tips backwards to be rolled out of the way. View our SB-5000 Portable Welding Screens which uses the same shade on a wheeled post.

Can these be electrically interlocked so the machine they are guarding does not start until the shade is pulled shut?

As far as using safety interlocks and proximity switches, that is something that you can do on-site if you have a controls company or if you have a capable maintenance person working at your facility. We don't provide any of the electronic devices required to make that set up but it actually is fairly common with customers as a retrofit that they install. Customers typically do this so that they can make sure the curtain is pulled shut before the equipment starts working.