Plasma Burn Table Curtain Walls

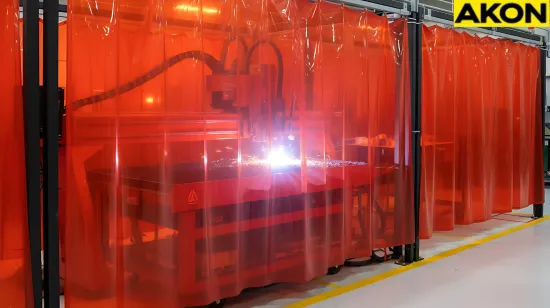

Plasma cutting produces sparks, UV and infrared radiation, molten metal, and fumes that put workers and equipment at risk. Containment is key for safety and efficiency. In this article, we’ll explain why welding curtains are the smart solution, explore material and layout options, highlight product recommendations, and answer common customer questions.

What Makes Welding Curtains a Smart Choice

Not every containment solution is practical for a busy metal shop. Permanent walls can be costly and inflexible, while open setups fail to protect workers and equipment. Welding curtains offer a practical middle ground, giving plasma burn table operators reliable containment that adapts to their workflow and keeps the shop running smoothly.

Welding Curtains vs Other Containment Options

Permanent walls may seem like a long-term fix, but they require large investments, lengthy construction, and make layout changes difficult.

Open setups are the opposite problem, leaving sparks, fumes, and harmful light to spread across the shop.

Welding curtains bridge this gap by delivering strong protection in a solution that is easier to install, maintain, and adapt over time.

Benefits That Support Your Shop’s Workflow

Welding curtains bring measurable advantages that permanent barriers cannot. They install quickly, cost less upfront, and can be moved or resized as your operation grows.

Curtains also let other shop activities continue nearby without exposure to sparks or glare.

With this flexibility, shops gain compliance, worker protection, and efficient use of space in one dependable solution.

Material, Shade, and Hardware Options

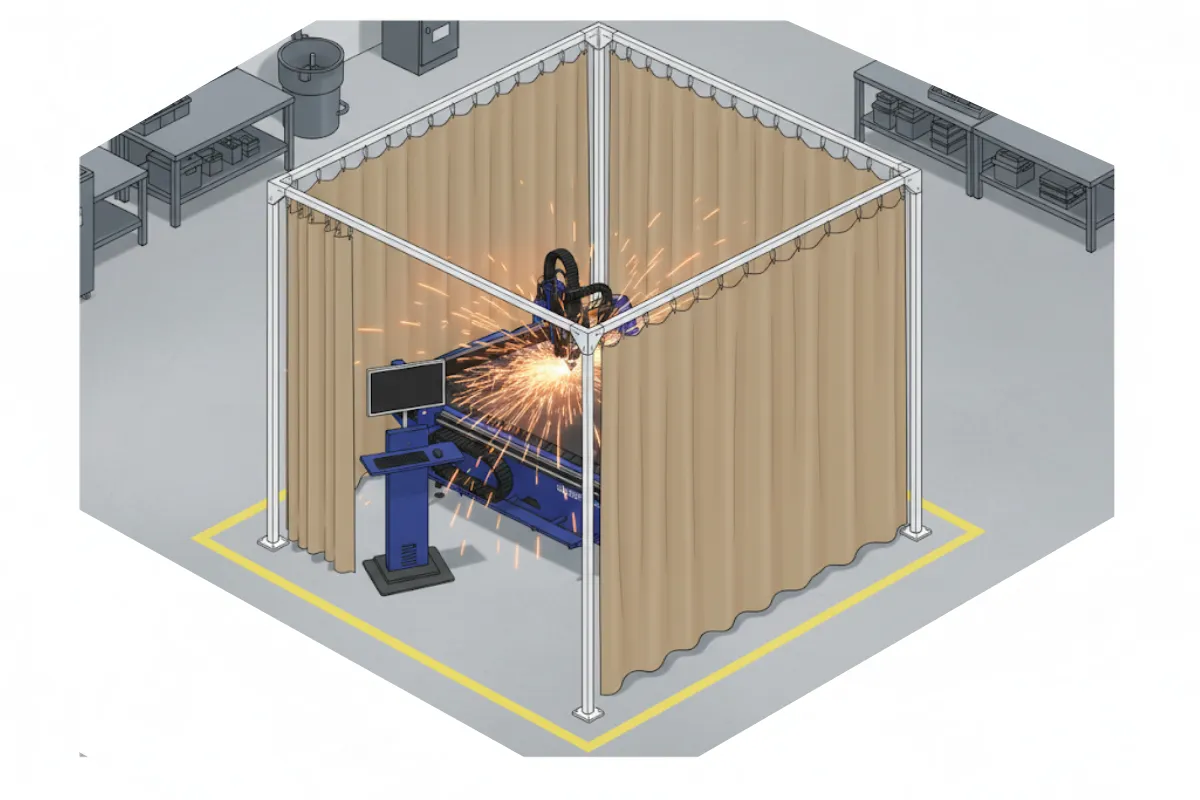

Once you understand why welding curtains are the smarter choice, the next step is selecting the right setup for your plasma burn table enclosure. The material, shade, and hardware you choose determine how well the enclosure performs in daily use, so it is important to match these details to your shop’s needs.

• Material Types: Flame-retardant vinyl is a strong choice for most plasma cutting environments because it combines durability with affordability. For tougher jobs, canvas offers greater resistance, while strip curtains allow quick entry and exit in busy areas without sacrificing containment.

• Shades and Visibility Options: Shades determine how much protection and visibility your curtains provide. Transparent panels support easy monitoring, while tinted options such as Shade 8 block harmful UV and infrared light to maintain safety and compliance.

• Hardware Choices: Hardware provides the structure that makes your enclosure work. Overhead tracks, retractable systems, floor sweeps, and grommets all help secure the setup and allow you to customize it to your space.

Durability

Heavy-duty vinyl and canvas are built to resist sparks, heat, and daily wear, ensuring your enclosure lasts even in demanding shops.

Flexibility

Tracks, retractable systems, and custom sizing make it easy to design an enclosure that fits your plasma burn table and adapts as your shop evolves.

Visibility

Transparent and tinted curtain options allow supervisors to monitor work while shielding employees from harmful light and flying sparks.

Configuration Options & Comparison Table

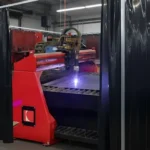

After selecting the right material, shade, and hardware, the next step is choosing the configuration that fits your shop. The layout of your plasma burn table enclosure affects how well sparks, fumes, and light are contained, as well as how easily workers can access the space.

| Option | Safety | Installation Cost/Time | Flexibility | Visibility | Maintenance |

|---|---|---|---|---|---|

| Welding Curtain Enclosures | High protection from sparks, light, and fumes | Moderate, quick to install | Highly adaptable and reconfigurable | Good with transparent or tinted panels | Easy to clean or replace sections |

| Rigid Walls / Permanent Enclosures | Very high, full separation | High cost, lengthy construction | Low, fixed once built | Limited without windows | Higher long-term upkeep |

| No Enclosure / Open Setup | Low, hazards spread freely | No upfront cost | High, but unsafe | Full visibility | Minimal, but higher safety risks |

By understanding your layout options and how they compare to other solutions, you can choose the setup that matches both your safety needs and shop workflow. Next, let’s look at specific welding curtain products that make these configurations possible and see which ones fit best for different shop environments.

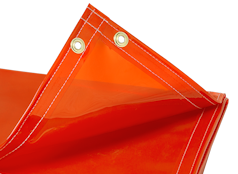

Opaque – 18oz

- Vinyl coated polyester reinforced with scrim

- Meets California Fire Marshal requirements CFM

- Finished edges for clean crisp appearance

- Double or triple hems used where needed for longevity

- All colors are the same price

- 18 oz = .020″ thick, 2.0 oz. per square foot

Tinted – 14mil, 40mil

- Ideal for welding applications

- Blocks most UV radiation for welding

- Meets California Fire Marshal requirements CFM

- Finished edges for clean crisp appearance

- Double or triple hems used where needed for longevity

- 14 mil = 14mil thick, 1.44 oz. per square foot

- 40 mil = 40mil thick, 3.95 oz. per square foot

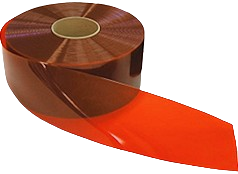

Strips – 8",12"

- Ideal for welding applications

- Blocks most UV radiation for welding

- Meets California Fire Marshal requirements CFM

- 8" wide strips | .080" Thick (ideal for booths)

- 12" wide strips | .120" Thick

- Studded strip or steel tube mounted

Product Spotlight: Recommended Welding Curtain Systems

Now that you’ve seen how different configurations work, it’s time to look at the actual products that make them possible. We offers several welding curtain systems designed to handle plasma burn table operations safely and efficiently.

Heavy-Duty Industrial Welding Curtains

For shops that need maximum durability, these heavy-duty curtains provide strong, long-lasting performance. They’re built to resist sparks and heat from the most demanding plasma cutting tasks.

• Made from flame-retardant vinyl with reinforced seams.

• Best for high-amperage plasma tables and continuous heavy cutting.

• Commonly used in large fabrication shops to create enclosed zones for compliance and worker safety.

Retractable Curtain Track System

When space must stay flexible, retractable track systems are the go-to solution. They let you open or close off the plasma table area quickly, depending on the task at hand.

• Curtains glide smoothly along overhead tracks for easy access.

• Perfect for medium-sized shops with multipurpose work areas.

• Allows quick transitions between cutting and other shop activities.

Portable Welding Screens

Small shops and mobile workstations benefit most from portable welding screens. They deliver the same safety protection as larger systems but can be moved wherever needed.

• Lightweight frames with flame-retardant vinyl panels.

• Best for small shops or temporary plasma cutting jobs.

• Frequently used for one-off projects or setups that move around the floor.

Frequently Asked Questions

FAQs: Plasma Burn Table Enclosures with Welding Curtains

What is the safest way to contain sparks from a plasma burn table?

The safest method is using a welding curtain enclosure. Our heavy-duty industrial welding curtains are flame-retardant and block sparks, heat, and light, keeping your shop compliant and your workers safe.

Do welding curtains really block UV and infrared light?

Yes. High-quality welding curtains filter harmful UV and infrared radiation while still allowing visibility. This ensures that cutting operations can be safely monitored from outside the enclosure.

How do I manage smoke and fumes inside an enclosure?

Pair your curtain system with fume extraction or a downdraft table. We designs enclosures that integrate easily with ventilation setups to keep air clean and safe.

Which welding curtains work best for high-amperage plasma tables?

Heavy-duty vinyl welding curtains are best because they withstand intense sparks and heat. They are ideal for large fabrication facilities where cutting is continuous.

Will welding curtains hold up under daily sparks and heavy use?

Absolutely. Industrial-grade curtains are made with reinforced seams and fire-resistant vinyl or canvas, giving them years of dependable service even under daily plasma cutting.

Can I reconfigure my welding curtain enclosure later?

Yes. Our systems are modular, meaning you can expand, move, or adjust the setup as your shop grows. Retractable systems are especially useful for layouts that change often.

How do I measure my plasma table for the right fit?

Measure the length, width, and height of the table, then add clearance space for airflow and safety. We can create a custom enclosure based on your exact shop dimensions.

Are welding curtains OSHA and NFPA compliant?

Yes, when properly installed. Our enclosures are designed to meet OSHA and NFPA standards, giving your business peace of mind with compliance.

Do welding curtains reduce noise from plasma cutting?

They provide some noise dampening but are not primarily sound barriers. For more noise control, you can combine curtains with acoustic partitions.

What are the color and shade options?

Curtains are available in clear, tinted, or opaque vinyl. Clear panels provide visibility, while darker shades like Shade 8 give maximum UV and IR protection.

How easy are welding curtains to clean?

They are low-maintenance and only need occasional cleaning with mild soap and water. This helps keep your shop looking professional and extends curtain life.

Can welding curtains be customized for unique shop layouts?

Yes. We can design custom sizes, retractable tracks, or strip curtain entry points to match your shop’s exact needs.

Do portable welding screens work as well as full enclosures?

Yes, they provide the same material protection but cover smaller areas. They are best for small shops or temporary projects that do not require a full booth.

Can I add entry points for workers or materials?

Yes. Strip curtain sections can be added for safe and convenient access without leaving large openings that expose the shop.

Do welding curtains require professional installation?

Not always. Smaller systems can be installed in-house, while large retractable setups may benefit from professional installation for the best fit.

Can welding curtains help keep my shop organized?

Yes. By enclosing your plasma burn table, you create a dedicated zone that separates sparks and fumes, freeing up surrounding space for other safe activities.

Are replacement panels available if one gets damaged?

Yes. We offers replacement panels so you can swap out a section without replacing the entire enclosure.

Do welding curtains interfere with ventilation systems?

No. When installed correctly, they work alongside fume extraction or downdraft systems to improve airflow and safety.

How quickly can welding curtains be installed?

Most setups are completed in just a few hours. Even large booths are far quicker to install than rigid walls, meaning minimal disruption to your workflow.

Where can I order welding curtains for plasma burn tables?

You can request a custom quote directly from us. The team will guide you in choosing the right curtain system for your plasma table and shop layout.

Your Next Step to a Safer, More Efficient Shop

Welding curtain enclosures give plasma burn table operators a proven way to boost safety, efficiency, and compliance. The next step is to measure your table, decide on the right material and shade, and plan your setup. We makes it easy, explore their welding curtain systems today and request a custom quote to build the enclosure your shop needs.