OVERVIEW

Chemical splash curtains are specifically designed to withstand corrosive chemicals and acids. Aside from providing protection to your property and employees, you can also customize these curtains to meet your project’s demands and needs. They can be fitted for indoor and outdoor purposes.

Rapid Deployment

Chemical Splash Containment

Chemical Splash Curtain Uses

Chemical splash curtains can be utilized in any facility that deals with chemicals, contaminants and odors. They are typically installed and used in:

- Chemical mixing plants

- Power plants

- Laboratories

- Chemical factories

- Schools

- Pharmaceutical facilities

Benefits of Installing Chemical Splash Curtains

Chemical safety curtains aren’t just about having protection against chemicals. They also have the following benefits.

- Reduces the cost of having to build permanent walls

- Can be customized as per the space, purpose and length of use

- Effectively controls contaminants, sound, light and even temperature

- Conveniently separates working areas

- Enhances privacy and working conditions

Available Sizes

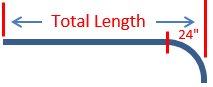

All our curtains are custom-made to ensure you get the perfect fit around the area which has the hazardous chemicals. Ideally, you should have your chemical splash curtains at around 30-40’ in width for easier installation. If you need to cover a wider space, you can simply install multiple curtains and connect them with Velcro strips or magnets.

Our curtains have a maximum height of 60’. In case of height issues, you can purchase valance panels to preserve your facility’s ceiling and to eliminate the additional cost of renovating the top half area of your structure.

Material Options

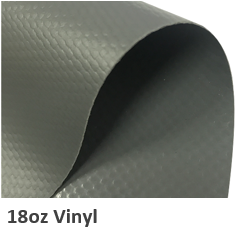

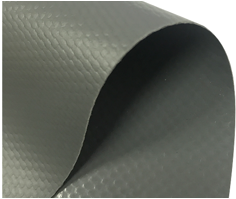

18 oz Reinforced Vinyl (standard)

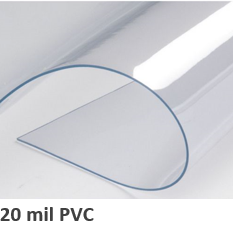

20 mil Clear PVC For Clarity

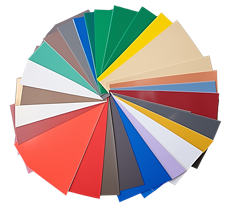

Available in Multiple Colors

Strong Materials

Splash Containment Enclosure

Freestanding Splash Enclosures

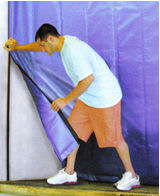

Freestanding splash enclosures are supported from the floor up with base plates. Ideal when top down ceiling mounting options cannot be used or are not ideal. The 16 gauge galvanized steel hardware is designed for rugged industrial use and is quick to deploy and to take down if need be. The freestanding uprights are spaced every 8 to 10 feet allowing for complete access when the splash enclosure curtain is pulled back. Entry options such as strip curtains can also be added for frequent access.

Choose From Two Styles

Strip Curtains

You can choose between strip curtain doors, walls, replacement strips, and more. The strip curtain doors offer unique benefits. You can quickly enter or leave a room without the need to open or close anything. They provide chemical splash protection without hindering the movement of people or materials. The chemical resistant strip curtain walls are perfect for dividing and organizing different manufacturing processes. You can stretch them for long distances. You have rich a choice when it comes to shapes, colors, sizes, and designs. There is a solution if you already have the hardware. Our quick ship pre-punched PVC strips will do the job.

Solid Curtains

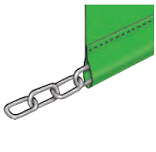

The most commonly used industrial splash curtains are heavy duty vinyl coated polyester fabric. Vinyl is the common name for PVC. Both are, in fact, the same material. The 18 oz. Material is either PVC Coated Polyester or PVC Laminated Polyester. Their exterior seams are made from rot-resistant nylon thread while their interior seams are heat welded to ensure that the curtains are sealed against air and liquid. The hems are chain-weighted using heavy duty galvanized chains so that the chemical splash curtains are stable enough to withstand draft. There are roller hooks so you can slide and retract the curtains on the track.

Complete Containment Solution

Frequently Asked Questions

Chemical splash curtains help protect nearby areas from accidental spills, splashes, and mist that come from working with strong liquids. These curtains create a safer space by keeping chemical spray contained so other workers and equipment stay protected. The material is made to resist damage from harsh cleaners and solvents, and it wipes clean with little effort. The curtains move smoothly when opening or closing, which makes them easy to use during busy work days. The purpose of this FAQ section is to provide you with useful and understandable information before you make a purchase.

Chemical Splash Curtain – Frequently Asked Questions

What is a chemical splash curtain used for?

A chemical splash curtain is used to protect workspaces from hazardous chemical splatter such as acids, solvents, and corrosive washdown. It creates a safety barrier around mixing areas, wash bays, processing lines, and containment zones.

What materials are chemical splash curtains made from?

Chemical splash curtains are made from coated vinyl, reinforced PVC, or polyurethane-laminated fabrics designed to resist corrosion, chemicals, and continuous moisture exposure.

Are chemical splash curtains resistant to corrosive chemicals?

Yes, they are engineered to resist acids, alkalis, solvents, and corrosive liquids. These materials are designed for harsh industrial and manufacturing environments.

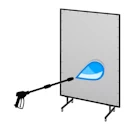

Can chemical splash curtains be used in washdown areas?

Yes, they are ideal for washdown zones. Their smooth, coated surfaces shed water and chemicals easily, making them suitable for repeated high-pressure cleaning.

Do chemical splash curtains include clear windows?

Yes, clear vinyl or polycarbonate windows can be added to allow visibility and supervision while maintaining full splash protection.

Are these curtains customizable?

Yes, they can be customized by size, layout, thickness, color, window placement, and hardware type to meet specific facility requirements.

Can I install a chemical splash curtain myself?

Yes, most installations are simple and can be completed using basic tools. Mounting options include tracks, cables, and wall brackets.

Do chemical splash curtains help contain fumes?

Chemical splash curtains help control splashes and directional spray but are not vapor-containment systems. Proper ventilation is still required for airborne chemicals.

Are chemical splash curtains fire-retardant?

Yes, most materials meet industrial fire-retardant standards. Check the specific rating if required for NFPA or facility compliance.

Can chemical splash curtains be used outdoors?

Yes, outdoor-rated models include UV-resistant coatings and stainless steel hardware to withstand sunlight, moisture, and corrosion.

How do I clean a chemical splash curtain?

Clean the curtain using mild soap and water. Avoid harsh solvents or abrasive tools to maintain the integrity of the protective surface coating.

Are replacement panels available?

Yes, individual panels and window inserts can be replaced without removing the entire curtain system, reducing downtime and maintenance cost.

Do chemical splash curtains resist acid wash?

Yes, when manufactured with chemical-rated materials they can withstand exposure to common acids used in washdown and industrial processes.

What mounting hardware options are available?

Mounting options include ceiling tracks, cable systems, wall mounts, stainless steel brackets, and roller assemblies for easy movement.

Can chemical splash curtains help with OSHA compliance?

Yes, they help create controlled chemical-handling zones and reduce splash exposure, supporting OSHA safety requirements for industrial facilities.

How long do chemical splash curtains last?

Chemical splash curtains typically last 3–7 years depending on chemical exposure, cleaning frequency, and environmental conditions.

Do chemical splash curtains reduce maintenance costs?

Yes, they protect floors, walls, and equipment from chemical damage, helping prevent corrosion and reducing repair and cleanup expenses.

Are clear windows scratch-resistant?

Many chemical splash curtains use scratch-resistant vinyl or polycarbonate windows, though gentle cleaning is recommended to maintain clarity.

Can chemical splash curtains be used with ventilation systems?

Yes, they integrate well with exhaust or fume extraction systems to help direct airflow and improve workplace safety, but they do not replace proper ventilation.

Curtain Track

- 16 gauge galvanized steel tracks

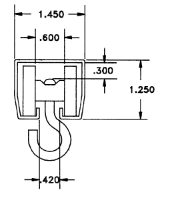

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.