Battery Testing Chamber Curtains

EV and lithium-battery labs need adaptable, contamination-free environments to keep up with rapid prototype changes. This article explains the key testing challenges labs face, the benefits of modular containment systems, how to build a temporary battery testing chamber, and which solutions best support safe, efficient, and scalable EV research.

The Challenge of Battery Testing in Electric Vehicle Labs

EV and lithium battery testing introduces a set of limitations that labs must navigate carefully. As prototype designs change and safety requirements increase, teams need testing areas that can adapt without compromising cleanliness or efficiency. Below are two core challenges that shape how modern labs plan their testing spaces.

Safety and Containment Challenges

EV battery tests generate heat, gases, and particulates that must be safely controlled to protect technicians and nearby equipment. Even smaller charge or discharge events can affect air quality or interfere with sensitive instruments.

Labs need reliable containment that isolates these risks while supporting accurate data collection and consistent testing conditions. This makes controlled separation essential for safe and repeatable prototype testing.

Layout, Cleanliness, and Budget Limitations

Shared lab environments make it difficult to maintain clean, separated test zones, especially when prototypes vary in size and chemistry. Engineers often need to update layouts quickly, but permanent builds slow progress and strain budgets.

Without flexible containment, routine adjustments can disrupt schedules and reduce overall testing efficiency. A setup that adapts quickly helps labs maintain productivity without sacrificing cleanliness.

Benefits of Modular Curtain Systems for Battery-Testing Chambers

As EV and lithium prototypes evolve, labs need testing areas that can shift just as quickly. Modular containment systems offer a practical way to create clean, controlled spaces without slowing down ongoing research. Below are three core advantages these systems provide for fast-moving battery development teams.

• Minimal Disruption to Existing Labs: These systems install quickly without interrupting other work. The setup process is clean and efficient, allowing teams to keep ongoing experiments running smoothly. This helps labs add new testing zones without affecting productivity.

• Easy Maintenance: The surfaces are straightforward to clean. Smooth materials help prevent dust buildup, which is essential in high-precision battery environments. Routine upkeep becomes faster and more manageable for busy lab teams.

• Scalability for Future Growth: Expansion is simple as testing needs evolve. Additional panels or sections can be added without redesigning your entire workspace. This makes it easy for labs to scale operations as new battery technologies are introduced.

Speed and Flexibility

Modular systems let labs reconfigure testing zones in days, making it easy to adapt to new prototype sizes or testing requirements.

Safety and Containment

Fire-rated panels help isolate heat and off-gassing during testing to protect both technicians and surrounding equipment.

Cost Efficiency

These systems create clean, functional test areas without the delays and high costs that come with permanent construction.

Material Options

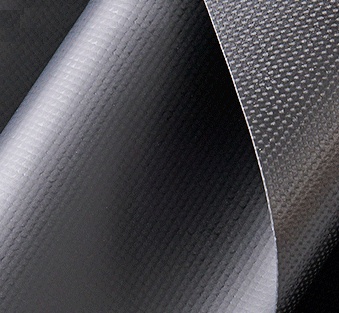

Vinyl

In areas where getting the curtain dirty is a concern we have the 18oz Vinyl curtains. Its slick surface makes it easy to clean and it is resistant to water spray. Unlike the fabric materials its surface is more reflective and shiny. This is the workhorse material that is made for less than ideal conditions. 100% Visual blackout, 90% Light blackout. $$

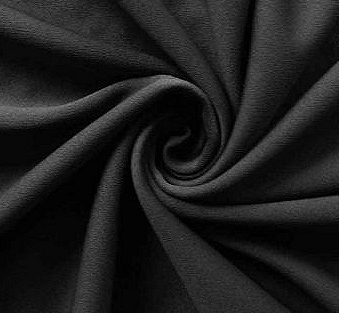

Fabric | Poly Stretch

Poly Stretch 6oz is a soft material commonly used in many commercial and industrial photo applications. It’s a two-way stretch fabric with zero, to minimal wrinkle and it has a flat matte finish. It is commonly used to create backdrop walls for photography of large products like automobiles. 75% Visual blackout, 50% Light blackout. $$

Fabric | Premium Velour

This luxurious 14oz fabric is ideal for stage backdrops, dividing a space or creating a high-end look with fabric. It's inherently flame resistant, lightweight and washable. It's the ideal fabric for commercial curtains that need to look great at a reasonable price. 100% Visual blackout, 90% Light blackout. $$$

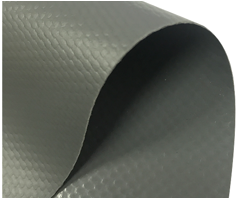

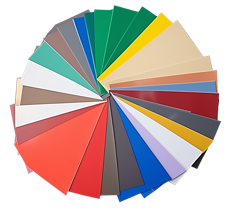

Material Options

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

How to Build a Temporary Battery-Testing Chamber

Creating a controlled testing space for EV and lithium prototypes can be done efficiently with the right approach. By following a structured setup, labs can build a chamber that supports safety, clean operations, and fast development timelines. The steps below outline a straightforward process for assembling a reliable containment area that fits your workflow.

| Step | Action | Key Consideration |

|---|---|---|

| 1 | Define layout and airflow | Map isolation zones and ventilation paths to support proper air movement during lithium testing. |

| 2 | Select materials | Choose fire-rated or anti-static vinyl that maintains clean conditions in sensitive lab environments. |

| 3 | Install track and frame | Mount overhead or use a freestanding system to create a modular structure that fits your available space. |

| 4 | Integrate safety systems | Add HVAC, exhaust, gas detection, and suppression to support controlled and secure test conditions. |

| 5 | Add power and data access | Seal cable entry points to maintain containment while giving equipment the access it needs. |

| 6 | Validate and reconfigure | Test airflow and sealing, then adjust the setup as needed before running full prototypes. |

Build a clean, safe chamber that supports rapid EV and lithium-battery prototyping without major facility changes.

Top Recommended Systems for EV Battery-Testing Chambers

After your chamber layout is established, the next step is choosing components that keep your testing space controlled, clean, and adaptable. Below are three reliable options that fit the needs of EV and lithium-battery labs when building temporary or reconfigurable containment areas.

Insulated Curtain Wall

These insulated panels are ideal for building test zones that require consistent thermal performance and added containment. They help create secure areas where heat, noise, and airflow need to be managed during active battery tests.

• Helps stabilize thermal conditions during high-heat or high-load battery testing

• Reduces noise transfer and improves containment around active prototype areas

• Works well for large enclosures or full-room battery-testing chambers

• Supports controlled airflow when paired with proper ventilation systems

Fabric | Poly Stretch

This flexible fabric solution is great for labs that need quick reconfiguration between different prototype setups. It divides shared environments cleanly without adding unnecessary barriers or requiring heavy hardware.

• Lightweight material makes reconfiguration easy during rapid prototype changes

• Ideal for separating areas in shared lab spaces without permanent construction

• Helps maintain visual separation between testing areas and workstations

• Offers a clean, professional look for both R&D and customer-facing environments

Fabric | Premium Velour

Premium Velour is an excellent choice for labs that want a polished, low-dust option that also supports clean testing practices. Its dense construction helps improve sound control while keeping test areas visually organized.

• Dense fabric helps absorb sound around active battery-testing zones

• Reduces visual distractions and creates clear boundaries in shared facilities

• Fits labs that want both functional separation and aesthetic appeal

• Easy to maintain and ideal for presentation-ready or high-visibility work areas

Frequently Asked Questions

FAQs – Common Questions About Battery-Testing Chambers

Can these systems meet clean-lab standards?

Yes. The smooth, anti-static materials used in these setups help maintain low-dust, contamination-controlled conditions. They are suitable for sensitive testing areas where cleanliness matters.

How fast can installation be completed?

Most setups can be installed and ready within a few days. Because everything is modular, your team can get new testing zones running quickly without interrupting other lab operations.

Are these systems suitable for lithium-ion or solid-state testing?

Yes, they work well for both. Fire-rated materials and proper airflow support safe testing during high-heat or high-load cycles.

Can the chamber control temperature or humidity?

Yes. Insulated Curtain Walls help stabilize environmental conditions when paired with your HVAC or climate-control setup. This is especially useful for thermal or humidity-sensitive tests.

Can I expand the chamber later?

Absolutely. Modular panels allow you to enlarge or reshape your containment area as your testing programs grow.

Do you help with design and layout planning?

Yes. Our team can help map out airflow, access points, and sizing based on your testing requirements to ensure everything fits your workflow.

Are these systems safe for high-heat discharge testing?

Yes. Insulated Curtain Walls support safer operation by helping isolate heat and reduce exposure to surrounding equipment.

Can these systems help reduce noise from large testing equipment?

They can. Premium Velour is especially helpful for reducing sound transfer around busy test areas.

Are the materials compatible with gas-detection and monitoring systems?

Yes. Chambers can include sealed ports for sensors, alarms, and gas-detection equipment.

Do the panels allow clear visibility for monitoring tests?

Yes. You can include clear or semi-clear sections so technicians can observe equipment without opening the enclosure.

Can this setup handle large EV battery packs or full assemblies?

Yes. Modular layouts can be built large enough to house full battery modules, racks, or connected testing equipment.

How durable are the materials used in these systems?

They are designed for long-term use. Most surfaces resist wear, abrasion, and frequent cleaning cycles.

Can these chambers help reduce cross-contamination between test cycles?

Yes. Poly Stretch and similar materials help divide testing zones to keep different chemistries and prototypes separated.

Do these systems require special tools for assembly?

No. Most components use basic tools and simple mounting hardware, making setup fast for most lab teams.

Can I run power or data lines into the chamber without breaking containment?

Yes. Sealed cable ports allow safe routing for power, sensors, and data connections while maintaining the chamber’s integrity.

Are the surfaces easy to clean?

Very. Smooth materials help prevent dust buildup and support quick wipe-downs in high-precision environments.

Are these systems flame-resistant?

Yes. Many materials meet fire-safety guidelines needed for EV battery testing, adding an extra layer of protection.

Can I relocate the chamber if lab needs change?

Yes. Modular components can be moved or rebuilt in another area without major downtime.

Can these systems integrate with existing exhaust or filtration equipment?

They can. Chambers can include vents or connection points that link to your facility’s extraction or filtration systems.

Are these chambers suitable for long-term or repeat testing projects?

Definitely. Their durability and flexible design make them ideal for ongoing battery-testing programs that evolve over time.

Build Safer, Smarter Testing Spaces

Modular solutions give EV and lithium-battery labs the freedom to create testing areas that support fast development without major facility changes. By using systems that adapt easily and maintain consistent performance, teams can focus on running safe, accurate tests as prototypes evolve. Create a battery-testing chamber that keeps pace with your innovation. Contact our team today to start your design.