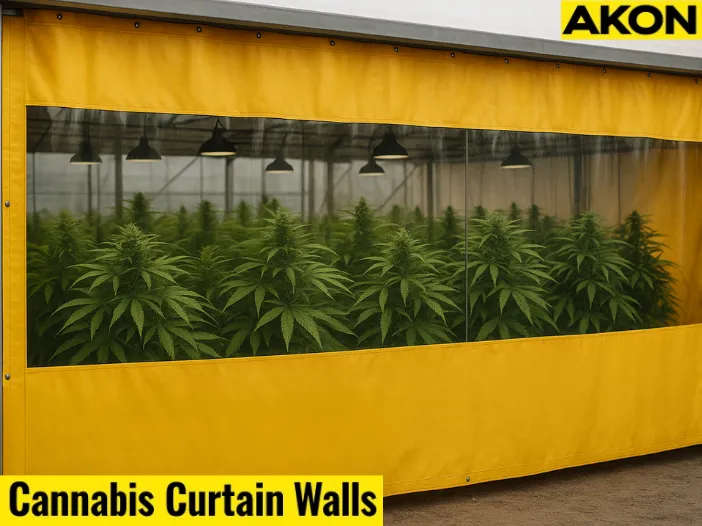

Cannabis Curtain Walls

Cross-contamination between cannabis strains can affect purity, compliance, and crop value. This guide explores how industrial curtain walls help solve that problem by creating flexible, sanitary, and affordable grow room separation. You'll discover key benefits, product comparisons, essential features, and answers to common grower questions.

Why Curtain Walls Are Perfect for Grow Room Separation

Control Matters in a Multi-Strain Grow Operation

As your cannabis operation expands, keeping strains isolated becomes more challenging. Each room or zone comes with its own environmental demands. Without proper separation, issues like odor migration, pollen drift, and unbalanced airflow can disrupt the consistency and quality of your grow. These challenges don’t just affect your plants, they impact your entire operation.

A Smarter Way to Separate Without Permanent Construction

Industrial curtain walls offer a clean, flexible way to divide your space without the cost or limitations of permanent walls. They give you better control over each phase of your grow, whether it’s veg, flower, or drying, while making it easier to adapt your layout as your needs evolve. With the right setup, you can reduce contamination risks and support a cleaner, more compliant facility.

Key Benefits at a Glance

Once you’ve identified the need for a more controlled grow environment, the next step is finding a solution that makes daily operations smoother, not harder. Here’s a quick look at why many cannabis growers are turning to industrial curtain walls.

Flexible Layouts

Quickly adjust your grow zones as needed. Curtain walls let you create new sections without construction delays, so your space works around your strains, not the other way around.

Cost-Effective

At roughly a third of the cost of permanent walls, curtain walls offer professional-grade separation without overextending your budget.

Sanitation Ready

Made from non-porous vinyl, these walls are easy to clean between harvests, helping you maintain a cleaner, pest-resistant environment.

Fast Installation

No need to put your operation on hold. Curtain walls install in hours using track systems or grommets, keeping your grow moving forward without major interruptions.

Curtain Walls vs. Other Grow Room Dividers

Choosing the right barrier for your grow room means balancing protection, flexibility, and practicality. Whether you're scaling up or fine-tuning your layout, it helps to compare your options side by side. Here's how industrial curtain walls stack up against permanent walls and plastic sheeting.

| Feature | Industrial Curtain Walls | Permanent Walls | Plastic Sheeting |

|---|---|---|---|

| Cost | Low: reusable and budget-friendly | High: includes labor, permits, and materials | Very low: but lacks long-term durability |

| Installation Time | Fast: typically done in a day | Long: often requires weeks | Instant: but rarely stable or secure |

| Flexibility | High: easy to move or reconfigure | None: fixed in place | Limited: moves, but lacks structure |

| Sanitation | Excellent: non-porous, easy to clean | Good: but harder to maintain in tight areas | Poor: absorbs moisture, tough to sanitize |

| Cross-Contamination Control | Strong: reduces airborne transfer with sealing options | Very strong: full physical barrier | Weak: prone to gaps and tears |

| Odor Containment | Moderate to high with sealing accessories | High: complete isolation | Low: odors easily pass through |

Industrial curtain walls offer an ideal balance of cost, flexibility, and protection for grow rooms. They install quickly, adapt to layout changes, and provide strong environmental control without the expense of permanent walls.

Material Options

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Curtain Wall Features Cannabis Growers Love

Now that you’ve seen how curtain walls stack up against other dividers, let’s take a closer look at the features that really matter to cannabis growers. These aren't just industrial partitions, they’re purpose-built for cultivation environments.

- Vision panels for visibility: Optional clear panels let you monitor plant growth, lighting, and staff activity without entering each room.

- Floor sweeps and Velcro edges for better sealing: These sealing accessories reduce airborne transfer and odor between zones by closing off gaps.

- Ceiling-to-floor coverage for full containment: Full-height curtains provide vertical isolation for complete environmental separation.

- Modular track systems that grow with your operation: Tracks allow you to easily slide or reposition curtain walls as your layout evolves.

- Fire-rated, USDA-grade vinyl for durability and compliance: Industrial-grade vinyl supports sanitation and meets fire and safety codes in cannabis grow rooms.

Curtain Wall Products Made for Cannabis Grow Rooms

Ready to level up your grow room setup? These curtain wall systems are designed with cannabis cultivators in mind, helping you separate strains, manage airflow, and stay compliant with less hassle.

Standard Industrial Curtain Walls

Looking for a dependable, everyday solution to divide your grow zones? These curtain walls are a cost-effective favorite for cannabis facilities that need flexibility without permanent construction.

• Cost-effective and easy to install

• Made from non-porous vinyl for easy sanitation

• Great for dividing veg, flower, or drying areas

Insulated Curtain Walls

Need tighter climate control in your grow? These insulated curtain walls help regulate temperature and humidity to keep your plants in their optimal environment, especially in large or multi-zone operations.

• Helps regulate temperature and humidity

• Ideal for precision climate control in sensitive grow environments

• Available in various insulation thicknesses

Curtain Walls with Vision Panels

Want a clearer view of your grow without breaking containment? These curtain walls include built-in vision panels so you can monitor plant health, lighting, and staff movement without entering each room.

• Transparent sections allow visual access to grow zones

• Improve efficiency by monitoring without entering rooms

• Maintain zone separation while boosting oversight

Frequently Asked Questions About Machine Guarding

FAQs – Cannabis Curtain Walls and Cross-Contamination

Do industrial curtain walls prevent cross-contamination between cannabis strains?

Yes. Industrial curtain walls help reduce cross-contamination by forming physical barriers that limit airborne pollen, spores, and odor from moving between zones, especially when paired with floor sweeps and Velcro seals.

Can I use industrial curtain walls in a humid grow room?

Absolutely. Our curtain walls are made from moisture-resistant, non-porous vinyl that’s designed to perform in high-humidity environments, making them ideal for cannabis cultivation spaces.

How long does it take to install an industrial curtain wall system?

Most installations take just a few hours. Industrial curtain walls can be mounted using ceiling tracks or grommets and don’t require permanent construction or downtime.

Can I reconfigure curtain walls if I change my grow room layout?

Yes. Industrial curtain walls are modular and retractable. You can move or adjust them anytime to create new zones or workflows without tearing anything down.

Are industrial curtain walls compliant with cannabis regulations?

Many curtain wall systems are built with fire-rated and USDA-grade vinyl materials, helping support sanitation and safety compliance in regulated grow facilities.

How do I clean curtain walls between harvests?

Wipe down the panels with a mild cleaning solution and a soft cloth. The non-porous surface is designed for fast sanitation, helping you meet cleanliness standards between cycles.

Do curtain walls help with odor control in cannabis grow rooms?

Yes. When paired with accessories like floor sweeps and edge seals, industrial curtain walls help reduce odor migration between flowering zones and vegetative areas.

Do I need a contractor to install curtain walls in my facility?

No. Most industrial curtain wall systems are DIY friendly with straightforward instructions. However, larger installations may benefit from professional support.

Can I use curtain walls to separate veg, flower, and drying zones?

Definitely. Industrial curtain walls are commonly used to isolate different grow phases to preserve light cycles, airflow, and environmental controls across rooms.

What heights do industrial curtain walls come in?

Curtain walls are custom-sized to fit your facility. Many cannabis growers opt for ceiling-to-floor coverage to maximize containment and separation.

Will curtain walls hold up to everyday grow room use?

Yes. Our curtain walls are built with heavy duty vinyl and reinforced stitching, making them durable enough for daily operation in high-traffic cultivation spaces.

Can I integrate curtain walls with grow lights or ventilation systems?

Yes. Curtain wall systems can be configured around lighting and HVAC units, or fitted with custom cutouts to work seamlessly with your existing setup.

Do industrial curtain walls affect airflow in grow rooms?

They can help direct and control airflow more effectively, especially when used with exhaust fans, intake filters, or pressure-controlled zones.

How do curtain walls compare to building permanent grow rooms?

Industrial curtain walls are faster to install, more affordable, and easier to adjust. Permanent walls may offer full isolation, but they lack flexibility and cost more upfront.

Are fire-rated curtain walls available for cannabis facilities?

Yes. We offer curtain walls made with flame-retardant materials that meet many local fire safety codes. You can request this option during customization.

What accessories can I add to an industrial curtain wall system?

Available add-ons include clear vision panels, Velcro sealing edges, floor sweeps, retractable track systems, and magnetic holdbacks for hands-free use.

Are curtain walls good for temporary or pop-up grow setups?

Absolutely. Their portability and easy breakdown make them a great fit for temporary grow operations, pilot programs, or testing new strain zones.

Do I need building permits to install curtain walls in my grow space?

In most cases, no. Because industrial curtain walls are considered non-permanent structures, they typically do not require permits, but always check local codes.

Can curtain walls block or filter light between different grow zones?

Yes. You can choose between opaque, translucent, or clear vinyl panels depending on your lighting needs and visibility preferences.

How long do industrial curtain walls last in a cannabis facility?

With proper care, industrial curtain walls can last for several years. They’re built for repeated use in demanding environments and are a smart long-term investment.

Flexible, Clean, and Cost-Efficient for Growing Operations

Industrial curtain walls help you grow smarter, not harder. Whether you're aiming to protect strain integrity, simplify compliance, or stay nimble as your operation evolves, these flexible barriers offer a strategic edge. Built for real cultivation environments, they’re cleanable, customizable, and durable enough to support your long-term success.