Spray Foam Insulation Booth Curtains

Curtain partitions make it easy to create a clean and controlled spray zone for contractors and DIY builders. They contain overspray, fit different spaces, and set up quickly without permanent walls. This guide walks you through the setup steps, key benefits, a comparison table, recommended booth options, helpful FAQs, and a short conclusion.

Step-by-Step Guide: How to Build a Spray Foam Insulation Booth

Setting up your spray foam booth is easy once you understand the space you are working with. This guide is built for contractors and DIY builders who want a clean spraying area without major construction. By planning the layout first and completing the booth structure second, you can create a safe and practical workspace for any project.

Plan Your Spray Area

Begin by measuring the space where you will work. Contractors may use a full shop bay or a section of a job site, while DIY users often work in a garage, driveway, or backyard. Once you know your dimensions, choose a mounting style that fits your setup.

Contractors often prefer ceiling or wall mounts, while DIY builders can use freestanding frames that fit smaller or temporary locations. Clear planning helps you avoid layout mistakes and makes the rest of the setup much easier.

Build and Complete the Booth Structure

After the mounting system is in place, start hanging your curtain panels. Contractors usually select heavy-duty vinyl for everyday spraying, while DIY users may prefer lighter or insulated panels for compact areas. Add side seals and floor sweeps to help keep foam in the spraying zone.

Finish by setting up ventilation, lighting, and basic safety equipment that matches the size and airflow needs of your workspace. This gives you a booth that works smoothly and supports better spraying results.

Why Curtain Partitions Work Perfectly for Spray Foam Booths

Once your booth is set up, the right curtain system helps you work cleaner and more efficiently, whether you spray foam on a job site or inside a garage or driveway at home.

• Better overspray control: Curtain panels help contain foam inside the booth so tools, vehicles, and surfaces remain protected. This makes it easier to maintain a tidy workspace during long spray sessions. It also helps reduce the time you spend on post-project cleanup.

• Flexible layout options: Panels glide along the track, allowing you to shape or resize the spraying area to fit your space. You can open sections when you need more room or close them when you want tighter control. This flexibility is helpful for growing shops and small home projects alike.

• Quick and affordable setup: This approach reduces setup time and avoids the cost of building permanent walls. It is an easy choice for contractors who move between job sites. DIY builders also benefit because the setup works well in garages, driveways, and other temporary spaces.

Overspray Control

Helps keep foam inside the spraying area so nearby surfaces stay clean.

Flexible Layout Design

Makes it easy to adjust the booth size to fit large shops or smaller home setups.

Fast and Cost-Efficient Setup

Lets you create a functional spraying area quickly without major construction.

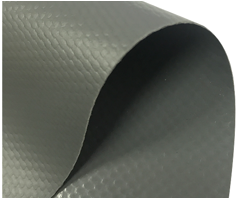

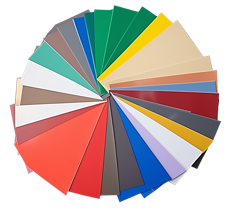

Material Options

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Selecting the Right Curtain Setup for Your Booth

Choosing the right setup helps you get better results from your spray foam booth. Contractors often need stronger materials and smoother hardware for daily work, while DIY builders usually look for options that fit smaller or temporary areas. The table below highlights the key features to consider so you can match your setup to the type of spraying you do.

| Feature | Why It Matters | Best for Contractors | Best for DIY Van or Home Builders |

|---|---|---|---|

| Material strength | Handles foam and frequent abrasion | Heavy 18oz vinyl | Standard vinyl or insulated panels |

| Track hardware | Supports smooth sliding and easy adjustments | Ceiling or wall-mounted tracks with rollers | Freestanding frames or quick-mount kits |

| Seals and floor sweeps | Helps improve containment | Full-perimeter sealing | Light floor sweeps for simple cleanup |

| Visibility | Offers clearer monitoring during spraying | Clear vision panels | Clear window inserts |

| Modularity | Makes booth resizing or relocation simple | Multi-bay configurations | Compact setups for garages and driveways |

With these features in mind, you can choose a setup that fits your space and the type of spraying work you do, whether it is a daily contractor project or a single DIY build.

Product Recommendations for Spray Foam Booth Setups

Here are three enclosure options that work well for both contractors and DIY builders. Each one supports different spraying needs and helps you build a workspace that fits your environment.

Clear Vinyl Enclosures

Clear vinyl panels are a great choice when you want full visibility inside your spraying area. They keep the booth bright and open while still providing the containment needed for clean results.

• Allows you to see your workspace clearly while spraying

• Helps monitor material coverage and equipment placement

• Lets natural or shop lighting pass through the booth

• Works well in small garages, shop bays, and van projects

Opaque Vinyl Enclosures

Opaque vinyl offers a solid barrier that helps you stay focused while spraying. It creates a cleaner-looking workspace and supports privacy in busy or shared areas.

• Helps block distractions around the booth

• Creates a solid barrier for light control and work focus

• Reduces visual clutter in shared or active workspaces

• Helps keep the booth looking tidy during and after spraying

Insulated Vinyl Enclosures

Insulated vinyl systems help maintain a more stable temperature inside the booth. They support better spraying conditions and add durability when working in seasonal or open environments.

• Helps keep temperatures steady for more consistent spray results

• Reduces the impact of heat or cold on foam performance

• Adds an extra layer of protection and strength

• Suitable for both large contractor spaces and home or van setups

Frequently Asked Questions

FAQs: Common Questions About Spray Foam Booth Enclosures

Will a vinyl enclosure actually hold spray foam inside a small workspace?

Yes, a vinyl enclosure can contain spraying in compact areas like garages or single-bay shops. Clear, opaque, and insulated options all form a defined work zone that helps keep the foam where it belongs.

Can I set up a spray booth enclosure even if I rent my shop or garage?

Yes, you can use freestanding or quick-mount setups that do not require drilling into the building. Clear and opaque vinyl enclosures work well for renters who want a temporary spraying space.

What enclosure works best for a small garage or driveway setup?

Clear vinyl enclosures are usually the easiest to use in tight spaces because they keep the area bright and open. They also help you see your tools and spraying angles clearly.

Do insulated vinyl enclosures help with spraying in cold weather?

Yes, insulated enclosures help stabilize temperatures so your foam cures more consistently. They are useful for contractors or DIY builders working in seasonal climates.

Can I move the enclosure if I rearrange my workspace later?

Yes, vinyl enclosures can be relocated or resized to match new layouts. Freestanding kits make this even easier when working in changing shop or garage spaces.

Which enclosure is best if I need privacy while spraying?

Opaque vinyl is the best choice when you want a clean and private spray zone. It blocks outside distractions and gives your booth a more professional appearance.

Will a vinyl enclosure help reduce cleanup after spraying?

A closed spraying zone catches foam before it drifts onto walls, floors, or tools. This makes cleanup faster for both contractors and DIY users.

Can I use these enclosures inside a van build?

Yes, compact clear or opaque vinyl enclosures work well in van projects that need a temporary spraying area. You can select custom sizing if your van interior is narrower than standard panels.

Do vinyl enclosures help with lighting inside the booth?

Clear vinyl improves lighting because it lets natural or shop light pass through the spraying area. If you need more control over light, opaque vinyl helps block bright reflections.

What enclosure works best for contractors who spray daily?

Heavy clear or opaque vinyl panels are common choices for daily use because they handle frequent spraying and regular movement. Insulated vinyl is helpful when temperature stability is important.

Can I order custom sizes if my shop is an odd shape?

Yes, all three enclosure types can be made to match unusual room layouts. You can request custom dimensions to get a clean fit around corners or tight areas.

Are clear vinyl enclosures strong enough for long spray sessions?

Yes, clear vinyl is durable and made for regular spraying. It helps you monitor your workspace easily while providing long-term containment.

Will insulated vinyl help with airflow comfort while I spray?

Insulated vinyl can help reduce drafts so the workspace feels more stable. It also helps prevent temperature swings that affect foam curing.

Can I set up an enclosure if my garage ceiling is low?

Yes, you can use shorter panel heights or freestanding frames for tight clearances. Clear and opaque vinyl both work well in low-ceiling setups.

What should I use if I want the booth to look cleaner on camera or photos?

Opaque vinyl gives a smooth backdrop that hides clutter. It is a good choice for contractors who record content or homeowners who want a cleaner look.

Do these enclosures help with airflow control around the spraying area?

Yes, vinyl panels help stabilize airflow so foam lands more accurately. Insulated panels offer even more control when the space is drafty.

Can I use these enclosures outdoors on a driveway?

Yes, vinyl enclosures can be used outside if anchored properly. Clear panels help maintain visibility when working in open areas.

How do I know which enclosure is right for my project?

Choose clear vinyl for visibility, opaque vinyl for privacy, and insulated vinyl for temperature stability. You can also combine panel types if your workspace has different needs.

Are vinyl enclosures easy to take down and store after a project?

Yes, all three enclosure types can be removed and stored without hassle. They are lightweight enough for DIY users to manage without special equipment.

Can I request help choosing the right enclosure size for my spraying area?

Yes, you can get help planning your layout and selecting the enclosure that fits your workspace. Custom recommendations make it easier to build a booth that suits your spraying needs.

Start Building Your Booth with the Right Setup

Using curtain partitions is one of the simplest ways to build a clean, flexible, and budget-friendly spray foam booth, whether you work in a shop, garage, or driveway. If you need help choosing between clear, opaque, or insulated vinyl panels or want guidance on sizing and layout, you can reach out anytime for recommendations or custom options that fit your spraying space.