OVERVIEW

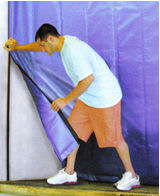

The heavy-duty industrial curtain walls are easy to roll from one side to the other. This retractable barrier can be opened and closed in only a few seconds. These industrial vinyl curtain walls are economical and quick to install at only about 1/3rd of the cost of a fixed permanent wall. Designed from various materials based on your application, the industrial curtains are built to last while preserving your budget.

Custom Made Per Application

Rapid Access In Any Size

AKON Quick Ship Industrial Curtains are a cost-saving solution for areas needing dust, temperature, and workspace zoning. They can be a temporary or long-term, aesthetically appealing and inexpensive solution. Designed to slide open quickly and easily on their roller hooks, the curtains provide rapid access for products and people to move through. They also meet fire retardant requirements as they are constructed of an 18 oz. Polyester-reinforced vinyl that has the NFPA-701 fire rating.

Less Expensive Than Fixed Walls

Easy Install

Industrial curtains come with grommets at the top, making hanging the curtains quick and easy with or without the curtain track.

Inexpensive

Industrial curtains are about 1/3rd of the cost of other separation methods such as rigid walls or panel systems and are easy to store.

Separate Workers

Industrial curtain walls are ideal for separating workers for welding, washing, packaging and many other operations.

Control Noise

Industrial curtains help reduce noise due to the thick PVC they are made from, which makes for a more comfortable work environment.

Ideal for Many Applications

Ideal Solutions For

- Dividing up manufacturing space

- Temperature control

- Dust control

- Paint or wash over spray control

- Smoke containment

- Humidity containment

- Welding spark containment

Key Benefits

- Less expensive than permanent walls

- Can be quickly installed and removed

- Ideal for the winter and summer weather

- Keeps your workers comfortable

- Seal off un-used warehouse space

- Reduce heating and cooling bills

- Contain dust, over-spray and odors

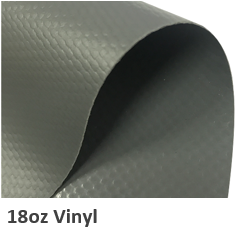

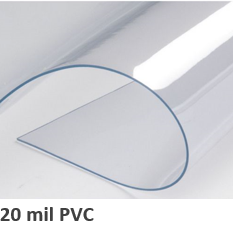

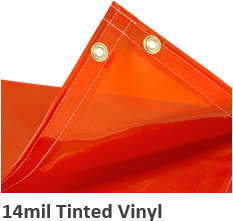

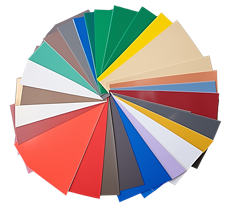

Material Options

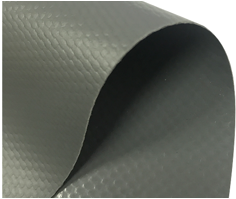

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Designed For Speed and Flexibility

Curtain Wall Applications

- Warehouse dividers curtains

- Insulated curtain walls

- Outdoor curtain walls

- Fabric curtain walls

- Wash down curtain walls

- USDA food grade curtains

- Garage divider curtains

- Welding divider curtains

- Body shop curtains

- Paint spray booths

- Hazmat curtains

- Aircraft hangar dividers

- Clean room curtains

- Dust containment curtain walls

- Machine guarding curtains

Available With Door Options

Access Points For Forklifts

Even though industrial curtains are retractable and are made to easily open and close, sometimes a fixed static position curtain wall can be ideal. With this type of installation, it's essential that foot traffic and motorized traffic still have access to both sides of the curtain. AKON can accommodate this requirement by installing strip curtains, swinging doors, and motorized roll-up doors. These components will allow for quick access without opening and closing the curtain wall.

Strip Curtain Access Points

Strip doors are an inexpensive door option for large vinyl curtain walls. Made from 8" wide PVC strips, they are crystal clear and eliminate the need for pushing back the curtain wall for access to the other side. A typical size is 36"w x 72"h, but it can be as large as you need it to be. These can be sewn into the curtain if the curtain needs to be retractable or mounted to a floor-anchored door frame supplied by AKON. Strips can accommodate both foot traffic and motorized traffic.

Works For Large And Small Areas

Form Work Areas or Divide Storage

Industrial curtain walls are a quick and easy install solution for making work zones or dividing warehouse space. For example, if a facility has different manufacturing processes in a large area, the curtain walls can form smaller work zones. That will help distinguish between work processes, protect workers and products from other processes, and contain cross-contamination.

Vinyl Curtain Walls Increase Work Flow

Industrial curtain walls provide a rapid and straightforward installation solution for the purpose of dividing warehouse space or establishing work zones. For example, these draperies can create smaller, designated zones in a facility with multiple manufacturing processes operating in a large area. This assists in the separation of workflows, the protection of employees and products from other processes, and the reduction of cross-contamination.

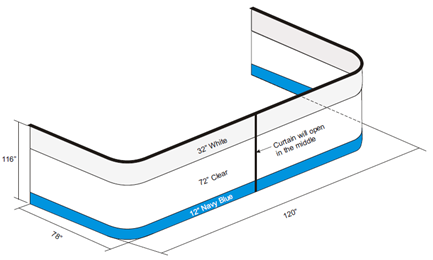

Made To Your Exact Dimensions

Custom Curtain Design

Each industrial vinyl curtain wall is custom designed to your exact specifications. Click the request for quote button at the bottom of this page, and our form builds your quote for you. You can choose your preferred color, width, height, vision panel, and curtain wall material.

Versatile Work Space Partitions

Photo Gallery

Frequently Asked Questions

Have questions about industrial curtain walls? You’re not alone. Many people want to know how they work, what they’re made of, and whether they’re the right fit for their space. To help, we’ve put together answers to the most common questions about features, benefits, and installation.

Industrial Curtain Walls – Frequently Asked Questions

What are industrial curtain walls?

Industrial curtain walls are heavy-duty vinyl or fabric partitions designed to divide work zones, contain dust or fumes, control temperature, and improve safety. Unlike permanent construction, they’re flexible, quick to install, and re-configurable when your facility layout changes.

What materials are used in industrial curtain walls?

They typically use industrial-grade vinyl, polyester scrim reinforcement, and optional insulation or acoustic layers. Frames and track systems often are galvanized steel or aluminum to ensure durability, corrosion resistance, and compatibility with heavy-duty environments.

Are industrial curtain walls fire-retardant?

Yes. Many systems are manufactured from fire-retardant materials and meet standards like NFPA for flame resistance. Always check the specification sheet to confirm that your selected curtain system complies with local fire and building codes.

Do curtain walls help with dust and debris control?

Absolutely. Curtain walls act as barriers to dust, airborne particles, and debris by sealing off production or finishing zones from open areas, thus helping to maintain cleaner workspaces and protecting sensitive equipment from contamination.

Can curtain walls help with temperature control?

Yes. Insulated vinyl or fabric options reduce heat transfer between zones, helping maintain cold- or warm-storage areas, or segregate climate-controlled spaces inside larger facilities. They’re much faster and more flexible than traditional walls.

How are curtain walls installed?

They can be mounted on ceiling tracks, pipe frames, or suspended structures and often use trolleys or sliding hardware. Installation is faster than rigid construction and often can be done without major downtime or structural modifications.

Can I customize the size and color of curtain walls?

Yes, most manufacturers offer custom widths, heights, colors, clear window panels, and even printed logos. Custom fabrication means the system can match your space and branding while fulfilling functional requirements.

Are industrial curtain walls movable or re-configurable?

Yes. One key advantage is modularity: sections can be relocated, slid open or closed, or expanded later as your workflow evolves. This flexibility sets them apart from permanent walls.

Do curtain walls block or reduce sound?

Standard vinyl walls offer some noise dampening, but acoustic-rated models with heavier fabric or insulation provide significantly stronger noise control between work zones. Ask about STC/NRC ratings for your application.

How durable are industrial curtain walls?

They’re designed for heavy-duty use, with reinforced seams, heavy-duty hardware, and vinyl or fabric engineered to resist tears, impacts and industrial wear. Properly maintained, they deliver years of service even in harsh environments.

Are curtain walls weather resistant for outdoor use?

Yes — outdoor-rated versions are available with UV-resistant vinyl, reinforcement and hardware suited to wind and moisture. Specify outdoor use when quoting so you get materials suited for exterior conditions.

What industries commonly use curtain walls?

They’re used in manufacturing, automotive shops, warehouses, food processing, cleanrooms, cold-storage, finishing bays, and any facility needing flexible zones. Their adaptability makes them ideal for evolving floor plans or multi-purpose facilities.

Can curtain walls be used outdoors or at loading docks?

Yes. Outdoor-grade curtain walls are suited for loading areas, exterior enclosures, or semi-exposed zones. They offer fast installation and flexibility without the permanence of new construction.

What maintenance is required for curtain walls?

Very little. Regular cleaning with mild soap and water is usually sufficient. Avoid harsh chemicals or abrasives. Periodically inspect hardware and seams to ensure safe, reliable performance.

Are curtain walls more affordable than permanent walls?

Yes. Because they avoid full construction, they install faster, cause less disruption and cost a fraction of traditional partition walls. Their modular nature also yields long-term savings when layouts change.

Can I add doors or windows to curtain walls?

Yes. Many systems integrate strip doors, roll-up doors, man-doors or clear vinyl window panels. This preserves workflow access while maintaining separation, visibility and functional zoning.

What is the typical lead time for curtain walls?

Lead times vary but most custom curtain wall systems ship within 2–3 weeks after order confirmation, depending on size and features. Some large or heavily customized jobs may take longer.

Do curtain walls meet safety or building regulations?

Yes. Many systems are engineered to meet OSHA and fire-safety standards, and can include FDA-approved or food-grade materials for sensitive areas. Verify the relevant certifications when selecting.

How long do curtain walls last?

With proper care and depending on environment, industrial curtain walls typically last 7–15 years or more. Lifespan depends on usage, exposure to elements and maintenance regimen.

Can curtain walls be re-configured if my layout changes?

Yes. One of the biggest advantages is modularity: panels and tracks can be moved, added or removed to adapt to new workflows or facility re-designs without full reconstruction.

What are typical cost savings compared to rigid walls?

Because curtain walls require fewer materials, less labor and less downtime, they often reduce cost by 40-60% relative to traditional partition walls in many applications. Always obtain a quote to confirm based on your job size.

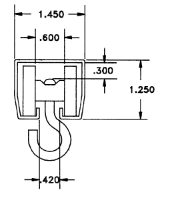

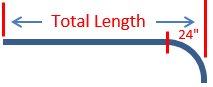

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.