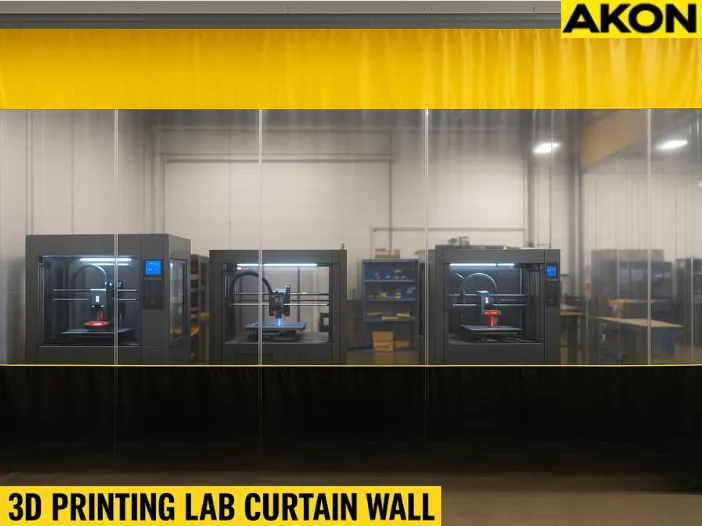

3D Printing Lab Curtain Walls

Airborne contaminants from 3D printing can harm health, equipment, and productivity. This guide explains why containment is critical, how curtain walls work, and product options. Learn how these quick install barriers improve air quality, protect staff, and give your lab the flexibility it needs without costly construction.

How Curtain Walls Keep 3D Printing Labs Air Clean

Keeping air clean in a 3D printing lab is about more than just comfort. The right containment system can protect health, improve print quality, and help the space meet air-quality standards without the cost of permanent construction. Industrial curtain walls offer a practical, adaptable way to achieve all three.

How Curtain Walls Contain Airborne Contaminants

Industrial curtain walls create an enclosed zone around high-emission 3D printers, trapping VOCs, resin fumes, and ultrafine particles before they circulate in the lab.

This targeted enclosure makes ventilation systems and exhaust units more effective by allowing them to pull contaminants directly from the source instead of the entire room. The result is cleaner air and a healthier environment for staff.

How Curtain Walls Improve Efficiency and Compliance

By separating printers from one another, curtain walls stop emissions from drifting into other work areas, helping maintain consistent print quality and reducing rework.

They also support compliance with OSHA, EPA, and local air-quality regulations by containing airborne hazards. Since they can be reconfigured as equipment or layouts change, they offer a cost-effective alternative to building permanent walls while keeping the lab adaptable.

Material Options

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

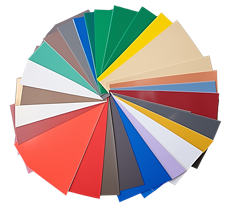

Available in Multiple Colors

Strong Materials

How Curtain Walls Work in 3D Printing Labs

With the risks clearly identified, the next step is choosing a containment method that addresses them efficiently. Industrial curtain walls are a proven option for 3D printing labs, creating a controlled zone around high-emission equipment so ventilation and filtration systems can work at their best.

Material Options:

Made from NFPA fire-retardant, lab-safe materials, curtain walls offer opaque vinyl in 13 oz, 18 oz, or 22 oz for privacy, and clear PVC in 20 mil or 40 mil for visibility. Both work in -25°F to 160°F conditions. This ensures safety, durability, and performance in demanding lab environments.

Customization Features

Custom options include vision panels, floor sweeps, and Velcro or magnetic seals for better containment. Galvanized steel track with nylon rollers ensures smooth movement and easy reconfiguration. These features make it easy to adapt the curtain walls as your lab’s needs evolve.

Fast Deployment

They allow for fast deployment, with most installations completed within hours so your lab can see immediate improvements in air quality and workflow efficiency.

Lower Cost

This solution offers a significantly lower cost compared to constructing permanent partitions while still delivering strong and reliable containment performance.

Adaptability

Their flexible design allows the walls to be moved or reconfigured whenever your lab’s layout, equipment, or operational needs change.

Choosing the Right Containment Solution for Your Lab

Once you understand how curtain walls function, it helps to see how they compare to other common containment approaches. The table below breaks down installation speed, cost, flexibility, and air quality control so you can choose the best fit for your 3D printing lab’s needs.

| Solution Type | Installation Speed | Cost | Flexibility | Air Quality Control |

|---|---|---|---|---|

| Curtain Walls | Very Fast | Low (about one-third the cost of permanent partitions) | High (custom layouts and easy relocation) | High (localized containment) |

| Permanent Partitions | Slow | High | Low | High |

| Open Layout + HVAC Only | N/A | Medium–High | None | Limited |

This side-by-side view makes it clear that while permanent partitions and HVAC improvements have their place, industrial curtain walls deliver the fastest, most adaptable, and most cost-effective containment for high-emission areas in 3D printing labs.

Top Curtain Wall Solutions for Safer, Cleaner 3D Printing Labs

Choosing the right curtain wall setup can make all the difference in how effectively your 3D printing lab controls emissions and maintains a safe, efficient workflow. Here are three proven solutions from our Industrial Curtain Walls collection that can be tailored to your space:

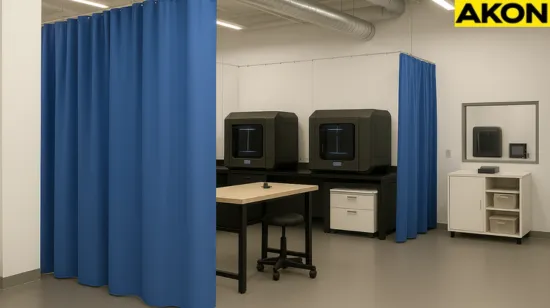

Opaque Safety Barrier

For labs that demand the highest level of separation, this heavy-duty vinyl barrier delivers complete isolation between printing areas and clean zones. It’s a dependable choice for strict containment without sacrificing durability.

• Creates complete visual and airflow separation between printing areas and sensitive zones

• Heavy-duty vinyl blocks VOCs and ultrafine particles from spreading

• Ideal for labs requiring strict isolation and controlled environments

Clear Monitoring Curtain

When you need both visibility and protection, this curtain offers the perfect balance. It lets you keep an eye on your printers without letting emissions escape into shared spaces.

• Transparent PVC allows safe, real-time monitoring of printers

• Contains airborne particles without obstructing workflow oversight

• Suitable for collaborative or educational lab environments

Floor Sweep and Magnetic Seal Curtain

For maximum sealing power, this option enhances any curtain wall with bottom sweeps and magnetic side seals. It’s designed to minimize air leakage and keep your containment zone as secure as possible.

• Adds bottom sweeps and magnetic side seals for maximum air containment

• Improves energy efficiency by reducing air loss

• Best for labs that need enhanced sealing for precision projects

Frequently Asked Questions About Machine Guarding

FAQs – Curtain Walls in 3D Printing Labs

How long does it take to install curtain walls in a 3D printing lab?

Most industrial vinyl curtain walls can be installed in a single day. The track-mounted system allows for quick setup without disrupting your 3D printing workflow.

Can curtain walls work with my existing ventilation system?

Yes. By isolating high-emission printing zones, PVC curtain walls improve your ventilation system’s efficiency and make filtration more effective.

Are curtain walls custom-fitted to each lab?

Absolutely. Each containment barrier is built to match your lab’s layout, printer locations, and workflow, ensuring a perfect fit.

How easy are they to clean?

Vinyl and PVC surfaces wipe clean with common lab disinfectants, making them ideal for maintaining a hygienic and professional workspace.

Are 3D printing curtain walls fire safe?

Yes. All models meet NFPA fire-retardant standards, giving you safety compliance without sacrificing performance.

Can I move or reconfigure them later?

Yes. Industrial curtain walls are designed for flexibility, allowing you to easily relocate or reconfigure them as your equipment or lab needs change.

Will they block both VOCs and ultrafine particles?

When paired with proper ventilation, heavy-duty vinyl curtain walls can significantly reduce VOC and UFP spread in high-emission printing areas.

Can I see my printers while they’re contained?

Yes. Clear PVC curtains with vision panels allow safe, real-time monitoring of your printers without releasing airborne contaminants.

Do they help control temperature in the print area?

Yes. By containing heat and airflow, vinyl curtain walls help maintain stable conditions for sensitive 3D printing materials.

Are they suitable for educational labs?

Definitely. Clear monitoring curtains let instructors observe print jobs while keeping emissions away from students.

How do floor sweeps and magnetic seals help?

They close gaps along the bottom and sides of the curtain walls, improving air containment and energy efficiency.

Can I add these to only part of my lab?

Yes. Curtain partitions can be installed to enclose only the high-emission equipment, leaving the rest of the lab open.

Are curtain walls better than permanent walls for flexibility?

Yes. They provide similar containment but can be moved, expanded, or removed entirely without demolition costs.

Do they require special tools for installation?

No. Most setups only require standard hand tools, making them a fast, low-hassle solution for lab managers.

Will they affect lighting in my lab?

Not significantly. Clear PVC options let light through, while opaque vinyl can block light if privacy or light control is needed.

Can they reduce dust settling on my equipment?

Yes. By isolating your 3D printing zones, containment walls help minimize dust and debris on nearby sensitive equipment.

Are curtain walls a cost-effective option?

Yes. They typically cost about one-third of permanent partitions, making them a budget-friendly way to improve air quality.

Do you offer different thicknesses and materials?

Yes. Options include opaque vinyl in multiple weights and clear PVC in various thicknesses to match your lab’s needs.

Can curtain walls be combined with other safety measures?

Absolutely. They work best alongside proper ventilation, filtration, and PPE for a complete air quality strategy.

How can I get a quote for my lab?

You can request a custom quote based on your layout, equipment, and containment goals to get the right industrial curtain wall system for your space.

Upgrade Your 3D Printing Lab’s Air Quality Today

Curtain walls give 3D printing labs a fast, adaptable, and budget-friendly way to create safer, cleaner work environments. If you’re ready to upgrade your lab with a solution that fits your space and workflow, explore our Industrial Curtain Walls collection and request a custom quote today.