Training Zone Curtains

Confined-space entry training requires realistic indoor setups that meet OSHA standards. This article shows how modular curtain systems help safety trainers and OSHA programs create safe, flexible, and enclosed zones, covering challenges, key features, product options, and FAQs to design efficient, compliant, and cost-effective training environments.

The Challenge: Creating Safe Indoor Training Zones

Creating enclosed indoor areas for confined-space entry training can be difficult for many facilities. Trainers need realistic conditions that support multiple scenarios, yet most indoor spaces are not designed for these requirements. This makes it harder to deliver consistent, high-quality training sessions that feel safe and effective.

Why Indoor Confined-Space Setups Are Hard to Build

Most facilities have fixed layouts, limited ventilation, and restricted floor space, which makes it difficult to recreate enclosed training zones. Trainers also need room for different modules, so the setup must adapt quickly while still supporting safe, realistic conditions for each session.

These challenges make it harder to maintain consistency across repeatable training cycles.

Why Traditional Barriers Do Not Meet Training Needs

Permanent walls take too long to build and add significant costs, while lightweight dividers rarely provide the structure required for OSHA-focused training. These limitations make it challenging to update layouts, contain activity, or adjust the environment for new drills, leading many teams to look for more flexible alternatives.

As training requirements evolve, traditional setups often slow progress and reduce overall training effectiveness.

Why Curtain Systems Are Ideal for Confined-Space Training Zones

Modular curtain systems give training centers a straightforward way to create enclosed areas that meet OSHA confined-space requirements without long construction timelines. They let trainers adjust the layout for new drills, maintain safe working conditions, and keep sessions running smoothly throughout the year.

• They help convert open areas into controlled zones. This makes it easier to create enclosed simulations without modifying the building or closing off permanent rooms. It also allows trainers to use wide, open spaces more efficiently while keeping each drill clearly defined.

• They reduce noise transfer during sessions. This separation helps different training groups stay focused without distraction. It also improves communication because trainees can hear instructions clearly in their designated area.

• They support portable or temporary setups. This flexibility is ideal for teams that share facility space or rotate training locations. It also allows trainers to set up, use, and remove their enclosed zones without interrupting other operations on site.

Safety and Compliance

They create enclosed zones that help contain fumes, dust, or debris during confined-space simulations.

Flexibility and Reconfiguration

Track-mounted panels let trainers adjust layouts quickly for different drills or training modules.

Visibility and Supervision

Clear vinyl sections allow instructors to monitor trainees without interrupting the exercise.

Material Options

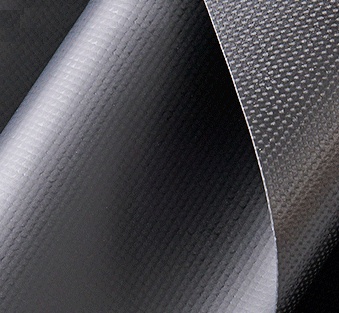

Vinyl

In areas where getting the curtain dirty is a concern we have the 18oz Vinyl curtains. Its slick surface makes it easy to clean and it is resistant to water spray. Unlike the fabric materials its surface is more reflective and shiny. This is the workhorse material that is made for less than ideal conditions. 100% Visual blackout, 90% Light blackout. $$

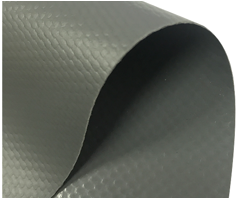

Fabric | Poly Stretch

Poly Stretch 6oz is a soft material commonly used in many commercial and industrial photo applications. It’s a two-way stretch fabric with zero, to minimal wrinkle and it has a flat matte finish. It is commonly used to create backdrop walls for photography of large products like automobiles. 75% Visual blackout, 50% Light blackout. $$

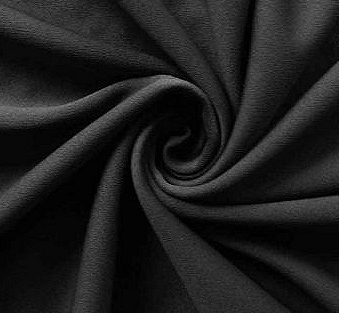

Fabric | Premium Velour

This luxurious 14oz fabric is ideal for stage backdrops, dividing a space or creating a high-end look with fabric. It's inherently flame resistant, lightweight and washable. It's the ideal fabric for commercial curtains that need to look great at a reasonable price. 100% Visual blackout, 90% Light blackout. $$$

Material Options

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

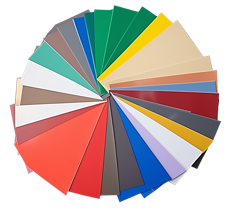

Available in Multiple Colors

Strong Materials

Key Features to Compare

Once trainers understand the benefits of modular setups, the next step is choosing which solution fits their facility. The comparison below offers a quick reference so safety teams can see how permanent walls, basic dividers, and modular systems perform in real training environments.

| Feature | Permanent Wall | Basic Divider Panel | Modular Curtain System |

|---|---|---|---|

| Installation Time | Weeks to months | 1 to 2 days | 1 to 3 days |

| Cost | High | Low to moderate | Moderate with strong durability |

| Flexibility | None | Limited | Fully adjustable |

| Visibility | None | Partial | Optional clear sections |

| Best For | Fixed structures | Light separation | Training zones and OSHA simulations |

Modular curtain systems offer the strongest balance of structure and adaptability, making them a reliable choice for trainers who need enclosed areas that can be reconfigured quickly. They support safe, repeatable confined-space sessions without the long build times or rigid designs associated with permanent construction.

Top System Choices for Confined-Space Training Areas

Different training areas have different needs, so choosing the right curtain helps trainers build controlled, OSHA-ready environments that match their layout and training style. Below are three dependable options commonly used to create enclosed, flexible, and professional confined-space training zones.

Insulated Curtain Wall

This option is ideal for training spaces that need stronger environmental control or airflow management. It helps trainers create enclosed areas that feel closer to real confined-space conditions while supporting safe and consistent training sessions.

• Helps maintain consistent airflow and temperature inside the training zone.

• Creates a stable barrier for drills that require tighter containment.

• Works well in wide training bays where full coverage is needed.

• Supports long-term durability for facilities running frequent sessions.

Fabric | Poly Stretch

This stretchable fabric panel gives training areas a clean, modern look without requiring permanent construction. It also helps facilities reconfigure their setup quickly when switching between different confined-space modules.

• Fits custom widths and heights for unusual layouts or multipurpose rooms.

• Provides a wall-like appearance without permanent construction.

• Great for facilities that regularly change their training setup.

• Easy to move or reposition as modules shift throughout the year.

Fabric | Premium Velour

This soft, professional-grade fabric is ideal for training environments where noise control or visual separation is important. It offers a more refined appearance while still supporting clear division between different drills or instructor areas.

• Helps reduce noise transfer between training groups.

• Offers a clean, refined look for instructor viewing areas or open classrooms.

• Supports clear separation between drills without feeling industrial.

• Useful when training areas sit close to other facility activities.

Frequently Asked Questions

FAQs: Indoor Confined-Space Training Systems

Are your indoor training enclosures compliant with OSHA confined-space rules?

Yes. Systems like insulated curtain walls and stretch-fabric panels can be built with fire-rated, industrial-grade materials that meet OSHA confined-space guidelines. They also support proper egress design for safe training flow.

How long does it take to install one of these training systems?

Most facilities can have their setup installed in one to three days. The timeframe depends on the size of the training area and whether you choose insulated walls, poly stretch fabric, or velour panels.

Can these enclosures help control fumes or small particles during drills?

Yes. Vinyl-backed materials and sealed edges help limit airflow and reduce particle movement inside the training zone. Insulated curtain walls are especially effective for tighter environmental control.

Can we change the layout when switching to a new training scenario?

Absolutely. Track-mounted systems make it easy to slide panels or reposition enclosures when switching modules. Poly stretch fabric is especially helpful when frequent reconfiguration is needed.

Are these systems durable enough for frequent confined-space training cycles?

Yes. All three material types are built for long-term use and can handle repeated movement and daily adjustments. This makes them reliable for year-round OSHA training programs.

Can instructors observe trainees while keeping the space enclosed?

Yes. Enclosures can include clear-view sections to support visibility and safe supervision. This is helpful when running multiple drills back to back.

Do these systems help reduce noise between training groups?

To some extent, yes. Materials like premium velour help soften sound transfer, which is useful when several groups train at the same time.

Are these barriers good for multipurpose or shared facilities?

Yes. They are easy to set up, reposition, or remove, making them ideal for gyms, warehouses, or vocational schools that share indoor space.

Can training equipment or carts move through the enclosure easily?

Yes. Access points can be added for quick transitions, including strip-style openings or soft-entry panels. This keeps the enclosure sealed without slowing down training flow.

Can these systems be customized to fit irregular or tight room layouts?

Yes. Insulated walls, poly stretch fabric, and velour panels can all be sized to fit wide bays, corners, and unusual layouts.

Do you offer full-height and partial-height enclosure options?

Yes. You can choose the height and materials that match your training setup, whether you need full containment or simple separation.

How well do the materials hold up in high-traffic training environments?

They are designed for repeated use and can handle regular sliding, repositioning, and daily wear. This is especially true for insulated and vinyl-backed options.

Can these systems help simulate darker or restricted-visibility environments?

Yes. Opaque materials or premium velour panels can help create lower-light conditions for specific confined-space drills.

Will these barriers interfere with ventilation or HVAC systems?

No. When set up properly, they work alongside existing HVAC systems while still providing an enclosed training zone.

Can we divide a large training room into multiple confined-space stations?

Yes. Many training centers use these systems to split one large room into two or more focused simulation areas.

How easy is it to clean the panels after drills?

Most vinyl and fabric options can be wiped clean with standard solutions. Regular cleaning keeps the enclosure safe and ready for the next session.

Can these systems include emergency exit points?

Yes. Custom layouts can include designated exit areas that meet safe egress requirements. You can request layout guidance for this.

Are the materials resistant to moisture or humidity?

Yes. Coated vinyl, insulated layers, and treated fabrics are built to handle indoor industrial conditions.

Can we choose specific colors or fabrics to match our training space?

Yes. Options like poly stretch and premium velour come in multiple finishes so you can match your room or training environment.

Do you offer support to help us choose the right system for our facility?

Yes. You can send your room measurements or training goals, and support staff can recommend whether insulated curtain walls, poly stretch fabric, or premium velour is the best fit for your space.

Enhance Your Confined-Space Training Setup

Creating safe and realistic confined-space entry training zones becomes simpler and more efficient when facilities use modular barrier systems that align with OSHA guidelines and adapt to different training scenarios. These solutions help trainers build controlled, flexible environments without long construction timelines or major disruptions. Ready to modernize your confined-space training area? Contact us today for a free design consultation or quote.