Coolant Spray Containment Curtain Walls

Coolant overspray can cause safety hazards, damage equipment, and increase cleanup costs. The problem becomes more difficult with wide machining openings that can’t use a top rail. This article explains why top rails fall short, introduces portable containment solutions, highlights key features, showcases products, answers common questions, and guides you toward safer, cleaner operations.

Material Options

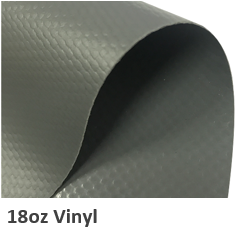

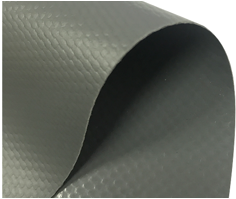

18 oz Reinforced Vinyl (standard)

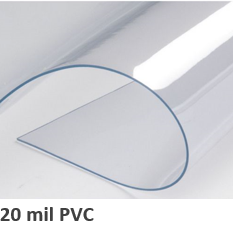

20 mil Clear PVC For Clarity

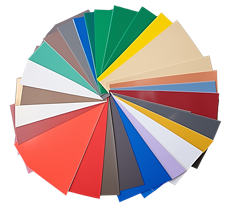

Available in Multiple Colors

Strong Materials

Why Top Rails Aren’t Always an Option

Many machining shops discover that top rails are not a practical choice for coolant spray containment. Large zones often require full overhead clearance, and structural layouts rarely support long, heavy rails. These limitations make it clear that another approach is needed. Portable alternatives give shops a way forward without major construction.

Clearance and Structural Limitations

Top rails are difficult to install in many facilities. Overhead cranes need unrestricted movement, ceilings may be packed with ducts or wiring, and structural supports are not always strong enough to carry the load.

These challenges leave shops searching for alternatives that won’t interfere with existing layouts. Portable dividers solve this by working independently of ceiling support.

This independence ensures that shop layouts remain functional without compromising safety or efficiency.

Why Fixed Walls Fall Short

Fixed walls might seem like a simple replacement, but they create more issues than they solve.

They are costly to build, reduce flexibility in changing workflows, and restrict access around machinery. Facilities that value efficiency and adaptability find portable dividers a better long-term investment.

They also avoid the downtime that comes with building permanent structures. Choosing portable dividers allows shops to scale and adapt quickly as production needs evolve.

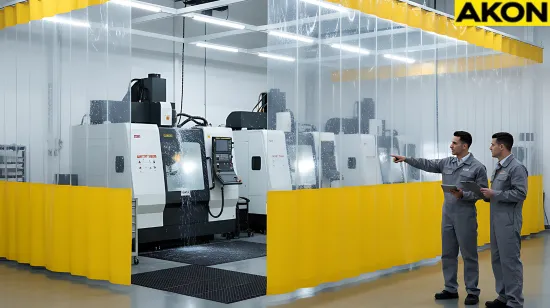

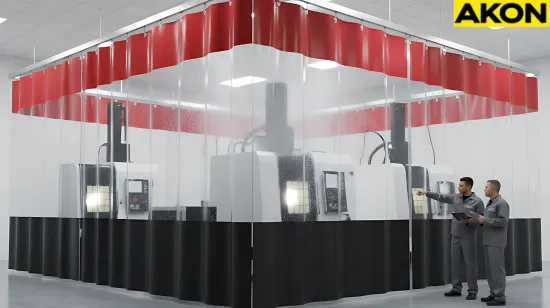

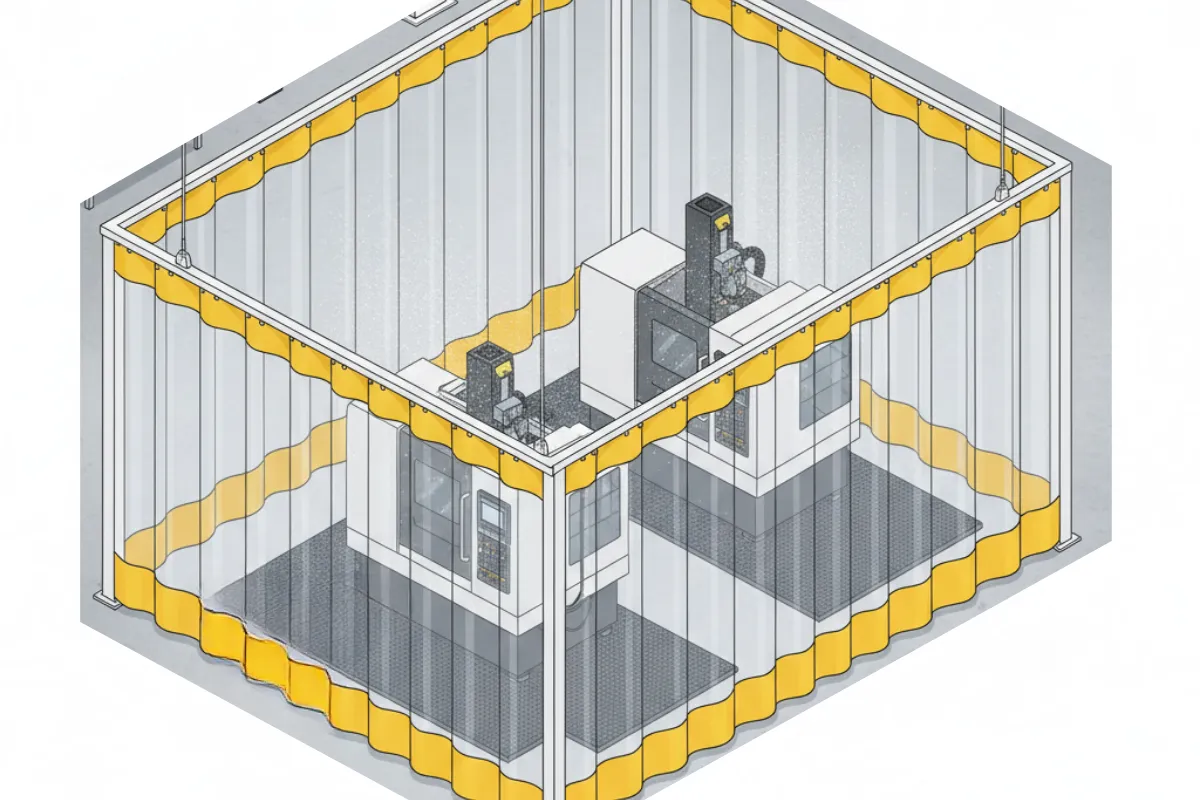

Portable & Modular Solutions to Prevent Coolant Spray

With top rails and fixed walls ruled out, shops need a flexible way to keep coolant spray under control. Portable and modular dividers are designed for this exact challenge. They offer durability, adaptability, and long-term performance without the hassle of permanent construction. By focusing on protection, visibility, and flexibility, these solutions give machining zones a safer and more efficient setup.

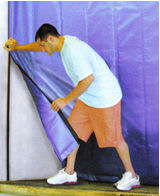

• Simple Setup. Portable curtain walls and dividers are quick to install and don’t require special tools. They can be moved or reconfigured whenever workflows change, even in areas with overhead equipment.

• Cost-Effective Choice. Unlike rigid walls, portable dividers are affordable and adaptable. They provide effective spray control without tying up budgets or interrupting shop operations.

• Built for Tough Environments. Heavy-duty vinyl and reinforced materials stand up to coolants, oils, and daily use. They are engineered to deliver lasting performance in demanding machining conditions.

Protection

Strong vinyl panels block coolant spray, keeping workers, floors, and equipment safe.

Visibility

Clear curtain walls maintain line-of-sight so operators can safely monitor machining zones.

Flexibility

Modular dividers span wide openings, without a top rail and can be repositioned as needed.

Choosing the Right Features for Your Shop

Once you know that portable dividers are the best way to control coolant spray, the next step is choosing the right setup for your shop. Not all systems are built the same, and a few key details will determine how effective and long-lasting your containment will be.

| Feature | Why It Matters | What to Look For | Customer Benefit |

|---|---|---|---|

| Durability | Dividers must withstand coolants, oils, and daily wear. | Heavy-duty vinyl or reinforced PVC | Reliable performance with fewer replacements |

| Sealing Overlap | Gaps allow spray and mist to escape. | Overlaps of 2 in. or more, plus side seals and bottom sweeps | Cleaner floors and better spray control |

| Transparency | Operators need visibility to monitor machines safely. | Clear PVC panels or built-in vision strips | Open line-of-sight with full protection |

| Modular Support | Wide spans can’t rely on overhead rails. | Floor-anchored posts and strong modular frames | Stable barriers for openings up to 32 ft |

| Flexibility | Shop layouts change and barriers must adapt. | Portable, reconfigurable sections | Quick adjustments without downtime |

By comparing these features, you can confidently choose a divider that not only contains coolant spray but also works with your shop’s layout and daily demands. Next, let’s look at specific products that deliver these features in real-world machining environments.

Best Products for Coolant Spray Containment

Now that you know the features to look for, here are three proven curtain wall solutions from the catalog that are built to handle coolant spray in wide machining zones.

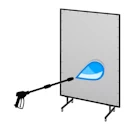

Machine Guarding Curtains

Machine guarding curtains are designed for machining areas where coolant and debris are a concern. They create a safe, enclosed zone that keeps spray under control and workers protected.

• Contains coolant spray, chips, and mist at the source

• Shields nearby staff and equipment from exposure

• Modular sections span wide openings without top rails

• Built with industrial-grade vinyl for daily wear

Wash Down Curtain Walls

Wash down curtain walls are built for facilities that need both containment and easy cleanup. They stand up to moisture, coolants, and frequent washing, making them a reliable option in spray-heavy environments.

• Moisture- and chemical-resistant materials for long life

• Smooth surfaces allow quick washdowns and sanitation

• Strong sealing options reduce leakage outside the machining zone

• Flexible design adapts to different shop layouts

Insulated Curtain Walls

Insulated curtain walls combine containment with climate control. They are ideal for machining areas where you need to stop spray while also improving temperature stability.

• Thick, insulated panels help reduce drafts and airflow

• Contain coolant spray while improving shop comfort

• High barrier strength for large openings

• Energy-efficient and adaptable to dynamic layouts

Frequently Asked Questions

FAQs: Coolant Spray Containment Solutions for Machining Zones Without a Top Rail

Can Machine Guarding Curtains span 32 ft without sagging?

Yes. Machine Guarding Curtains use floor-supported modular frames that cover spans up to 32 ft without overhead rails. They stay stable and secure for wide machining openings.

What’s the best material for coolant spray control?

Heavy-duty vinyl and reinforced PVC are the best options. Wash Down Curtain Walls and Machine Guarding Curtains both use these materials to resist coolants and daily shop wear.

Are curtain wall systems safe to use near CNC machines?

Yes. Machine Guarding Curtains are designed for CNC environments. They keep coolant spray and debris contained while operators safely monitor the process.

How do I clean and maintain Wash Down Curtain Walls?

They are made for easy cleaning. A quick rinse or wipe with standard solutions removes coolant residue and keeps the surface sanitary.

Can I order custom sizes or layouts?

Absolutely. Insulated Curtain Walls and Wash Down Curtain Walls can be customized in height, width, and layout to match your machining zone. Requesting a quote ensures the best fit.

Do curtain walls block visibility for operators?

No. Clear PVC panels or vision strips are available with Machine Guarding Curtains and PVC Strip Curtains, keeping line-of-sight open while containing spray.

How long do these curtain walls last in machining zones?

With proper use, Industrial Curtain Walls last for years. Reinforced vinyl construction handles coolants, oils, and heavy daily use.

Will coolant leak through the seams?

Not if you choose sealing features like overlaps, side seals, and bottom sweeps. Wash Down Curtain Walls include these options to stop leaks.

Can these dividers be moved if my layout changes?

Yes. Modular and portable designs let you reposition Machine Guarding Curtains or add sections without major effort.

Do they resist other shop liquids besides coolant?

Yes. Heavy-duty vinyl resists oils, chemicals, and cleaning agents, making these solutions versatile across machining environments.

Do curtain walls also help reduce noise?

Yes, to a degree. Insulated Curtain Walls provide the most sound reduction, while standard vinyl panels help soften ambient noise.

Can PVC Strip Curtains be used with curtain walls?

Yes. PVC Strip Curtains are often paired with Machine Guarding Curtains to allow easy access for people and equipment while containing coolant spray.

Do I need special tools to install these products?

No. Curtain wall systems install quickly with standard hardware. Many facilities set them up without specialized tools or outside contractors.

Are Insulated Curtain Walls useful in machining zones?

Yes. They provide coolant spray control and temperature stability, making them ideal for large shops that need comfort and energy efficiency.

Can these curtains handle frequent washdowns?

Yes. Wash Down Curtain Walls are built for frequent cleaning. They resist moisture and stand up to regular sanitation cycles.

Are there different color or finish options?

Yes. Choose clear for visibility, opaque for privacy, or custom colors to match safety zones or branding.

Will Machine Guarding Curtains interfere with overhead cranes?

No. They are floor-supported and do not rely on top rails, so they work well in facilities with overhead crane systems.

Can I replace damaged panels without replacing the whole wall?

Yes. These systems are modular, so individual curtain panels or strips can be swapped out to keep maintenance costs low.

Do these products meet workplace safety standards?

Yes. Materials are industrial-grade and commonly meet OSHA and NFPA requirements for fire resistance and safety.

How do I get a quote for my shop?

Request a custom quote with your dimensions and requirements. The team will recommend the right curtain wall system for your machining zone.

Contain Coolant Spray and Upgrade Your Shop Today

Managing coolant spray in wide machining zones doesn’t require costly construction or top rails. Curtain wall solutions provide dependable performance, adaptability, and safety for real-world challenges. Request a custom quote today to get the right containment system for your shop.

Machining Zone Divider Setup

Build Yours Online

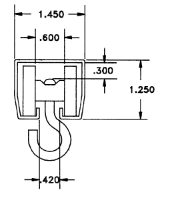

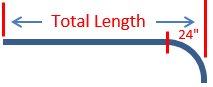

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.