Enclose Inspections Curtain Walls

A quality control inspection area must be enclosed to maintain efficiency, compliance, and clean workflows. This article explains the challenges facilities face, how curtain walls provide solutions, the features to consider, recommended product options, common questions, and why curtain walls are a smart alternative to costly permanent construction.

Common Challenges Facilities Face in QC or Inspection Spaces

Creating a quality control inspection area is not as simple as setting aside a corner of the facility. The space must meet strict requirements without slowing down operations or draining budgets. Below are two of the biggest challenges companies face when trying to create inspection zones that truly work.

Cost and Construction Limitations

Permanent walls often carry a high price tag and require long installation times, creating downtime that disrupts production schedules.

Once installed, they are also difficult to modify, leaving teams stuck with layouts that quickly become inefficient as inspection needs evolve.

This creates long-term expenses and limits a facility’s ability to stay agile.

Visibility, Containment, and Compliance Pressures

Inspection areas must provide clear visibility for inspectors while still keeping surrounding activity properly contained.

At the same time, compliance audits demand strict sanitation and easy cleanability, and when these standards are not met, the space can become a liability instead of a support to product quality.

These issues leave managers searching for a better solution that can balance all three needs.

Material Options

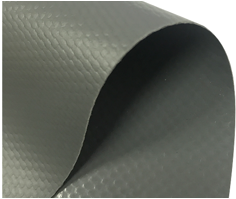

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

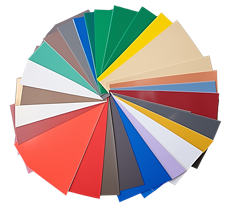

Available in Multiple Colors

Strong Materials

How Curtain Walls Address These Challenges

The challenges of building and maintaining inspection areas can feel overwhelming, but industrial curtain walls offer a smarter solution. They are purpose-built for facilities that need enclosed, compliant spaces without the disruption or cost of permanent construction.

• Faster setup and minimal downtime. Curtain walls can be installed quickly without interrupting production, allowing inspections to begin almost immediately. This speed makes them a practical choice for facilities where efficiency is essential.

• Adaptability for changing workflows. Modular by design, curtain walls can be reconfigured whenever inspection requirements shift or production layouts evolve. This flexibility keeps facilities agile instead of locked into an outdated setup.

• Regulatory peace of mind. Made from materials that align with GMP and FDA standards, curtain walls support compliance during audits. They are also easy to sanitize, helping maintain the cleanliness required for reliable inspections.

Cost Saving

At roughly one-third the price of permanent walls, curtain walls reduce upfront expenses and labor costs.

Flexibility

Reconfigurable layouts adapt to evolving inspection and production needs.

Visibility

Clear panels and integrated entry points keep inspections simple without sacrificing containment.

What to Look For in Curtain Walls

Once you understand how curtain walls solve common inspection challenges, the next step is knowing which features matter most for your facility. Each choice impacts how well the enclosure supports inspections, compliance, and daily operations. The table below highlights key features to consider and how they align with quality control needs.

| Feature | Why It Matters for QC Inspections | What to Look For |

|---|---|---|

| Material Type (opaque vs clear vinyl/PVC) | Controls visibility, privacy, and light within the inspection area | Clear panels for product checks, opaque vinyl for privacy or light-sensitive work |

| Weight/Thickness & Fire Rating | Determines durability, strength, and safety during audits | 18 oz vinyl or 40 mil clear PVC with NFPA-approved fire ratings |

| Sealing Options (floor sweeps, overlaps, ceiling seals) | Keeps dust, particles, and airflow from entering inspection zones | Floor sweeps and ceiling valances for a fully enclosed, clean environment |

| Access & Doors (strip doors, roll-ups, swinging doors) | Provides smooth workflow without breaking enclosure integrity | Door types matched to traffic levels, from staff access to equipment flow |

| Hardware & Track Systems | Ensures stability, durability, and long-term reliability | Ceiling-mounted or beam-clamp track systems built for frequent use |

By selecting the right combination of these features, facilities can design QC inspection areas that are both compliant and practical. In the next section, we’ll look at specific curtain wall solutions that bring these features together.

Recommended Curtain Wall Solutions

After understanding which features matter most, the next step is selecting the right curtain wall setup for your inspection area. Below are three proven solutions that combine compliance, durability, and flexibility for QC environments.

Opaque Vinyl Curtain Wall

For facilities that need privacy and dependable durability, the opaque vinyl curtain wall is a strong option. It creates a fully enclosed space that supports inspections without compromising on sanitation.

• Durable material built to last in demanding environments

• Provides privacy and strict containment for inspections

• Resists wear and frequent cleaning, making it easy to sanitize

•A cost-effective option for controlled QC spaces

Clear PVC Curtain Wall

When visibility is essential, the clear PVC curtain wall keeps inspections transparent and audit-ready. Its heavy thickness adds stability while still offering a clean, open view.

• Transparent design allows full visibility during inspections

• Strong 40 mil thickness provides stability and reliability

• Maintains separation from surrounding processes

•Ideal for audits and environments where observation is critical

Hybrid Solution with Clear Panels, Doors, and Floor Sweeps

For high-traffic facilities, a hybrid configuration combines flexibility and protection. By adding clear panels for visibility, doors for access, and floor sweeps for extra containment, this option adapts to complex workflows with ease.

• Combines visibility, access, and containment in one system

• Clear panels support inspections without breaking separation

• Doors streamline workflow for staff and equipment

• Floor sweeps add an extra barrier against dust and particles

Frequently Asked Questions

FAQs: Enclosing QC Inspection Areas with Curtain Walls

Are industrial curtain walls GMP and FDA compliant for inspection areas?

Yes. Products like 18 oz opaque vinyl curtain walls and 40 mil clear PVC curtain walls are manufactured to meet GMP and FDA standards, making them suitable for regulated inspections.

How easy is it to clean vinyl or PVC curtain walls between inspections?

Both opaque vinyl and clear PVC walls feature smooth, non-porous surfaces that resist buildup. They can be quickly sanitized using standard cleaning agents, ensuring audit readiness.

Can curtain walls for QC inspections be reconfigured if my production line changes?

Yes. Modular track systems allow opaque vinyl and hybrid curtain walls to be rearranged or expanded as workflows evolve, saving costs on redesigns.

How long does it take to install industrial curtain walls for inspections?

Most installations are completed in just a few hours. This makes them far faster and less disruptive compared to building permanent walls.

How long do opaque vinyl or clear PVC curtain walls typically last?

With proper care, both vinyl and PVC curtain walls can last 10 years or more, even in busy facilities with daily inspections.

Can curtain walls be customized to unique inspection area layouts?

Yes. Curtain walls are custom-built to match ceiling heights, slopes, and exact floor dimensions, ensuring a perfect fit.

Are clear PVC curtain walls strong enough for daily use in QC inspections?

Yes. The 40 mil clear PVC option provides durability while maintaining transparency, making it reliable for frequent audits.

Do curtain walls improve inspector visibility during quality checks?

Clear PVC panels are designed to provide full visibility, allowing inspectors to monitor products without compromising containment.

Can opaque vinyl curtain walls help with dust and particle control?

Yes. When combined with sealing options like floor sweeps and overlaps, vinyl walls create a clean, enclosed environment for inspections.

Can curtain walls be relocated to another part of the facility?

They can. Curtain walls are semi-permanent, meaning they can be disassembled and installed in a new location if workflows shift.

What access options are available for inspection areas with curtain walls?

Facilities can choose strip doors, swinging doors, or roll-up doors, depending on whether the area handles staff-only movement or equipment traffic.

Are industrial curtain walls fire-rated?

Yes. Many options, including opaque vinyl and clear PVC, are NFPA-701 fire-rated to meet safety requirements.

How do curtain walls compare in cost to permanent walls for inspections?

On average, curtain walls cost about one-third of permanent wall construction, making them a cost-effective alternative.

Do curtain walls interfere with lighting in the inspection area?

Not at all. Clear PVC panels allow natural and artificial light to pass through, while opaque vinyl sections can control brightness where needed.

Which curtain wall solution is best for high-traffic inspection areas?

Hybrid curtain walls with clear panels, doors, and floor sweeps are ideal. They balance access, visibility, and containment for busy environments.

Can branding or labeling be added to QC curtain walls?

Yes. Facilities can add custom colors, signage, or labels to curtain walls to improve safety and inspection zone identification.

Do curtain walls help control temperature or airflow in QC inspection zones?

Yes. With proper sealing, curtain walls reduce drafts and help stabilize conditions, which is critical for sensitive inspections.

Are industrial curtain walls permanent or temporary?

They are semi-permanent. Curtain walls are designed for long-term use but can be removed or adjusted as facility needs change.

Can curtain walls support different types of inspections, such as visual or mechanical checks?

Yes. Clear PVC panels support visual inspections, while opaque vinyl walls provide privacy for mechanical or sensitive testing.

How do I choose the best curtain wall setup for my inspection area?

Start by assessing your needs for privacy, visibility, and traffic flow. Then consider options like opaque vinyl, clear PVC, or hybrid solutions and request a custom quote tailored to your facility.

Ready to Enclose Your QC Inspection Area

Curtain walls give facilities a reliable way to enclose QC inspection areas without the delays or high costs of permanent construction. To get started, measure your space and request a custom quote from Curtain & Divider, and their team will design an inspection-ready solution tailored to your needs.