Fire Department Decontamination Zone Curtains

This article explains why decontamination zones are essential in fire stations and how flexible curtain systems help create safer, cleaner workflows. You will learn the basics of hot zone isolation, turnout gear cleaning, key features to consider, recommended setup options, and answers to common questions. It serves as a simple guide to improving your station’s post-incident process.

Why Decontamination Zones Matter for Fire Departments

Keeping a clean and controlled space after every call is essential for firefighter safety. A dedicated decontamination zone helps prevent harmful residue from spreading through the station and supports a healthier environment for both crews and their families.

Contaminants Left Behind on Turnout Gear

Turnout gear often holds soot, PFAS, carcinogens, and other harmful residue that can spread once firefighters return to the station.

Without a defined hot zone, these contaminants can reach living quarters, trucks, and equipment storage areas, creating additional exposure risks for the entire department.

A separate cleanup area limits how far these particles can travel once crews step inside.

Protecting Crews, Families, and the Station Environment

A structured decontamination zone helps keep hazardous particles contained in one controlled area, reducing unnecessary contact throughout the station.

This focused setup supports long-term health efforts for firefighters, protects their families, and aligns with modern cancer prevention practices many departments now prioritize for crew safety.

It also encourages a safer routine that reinforces consistent cleanup habits after every call.

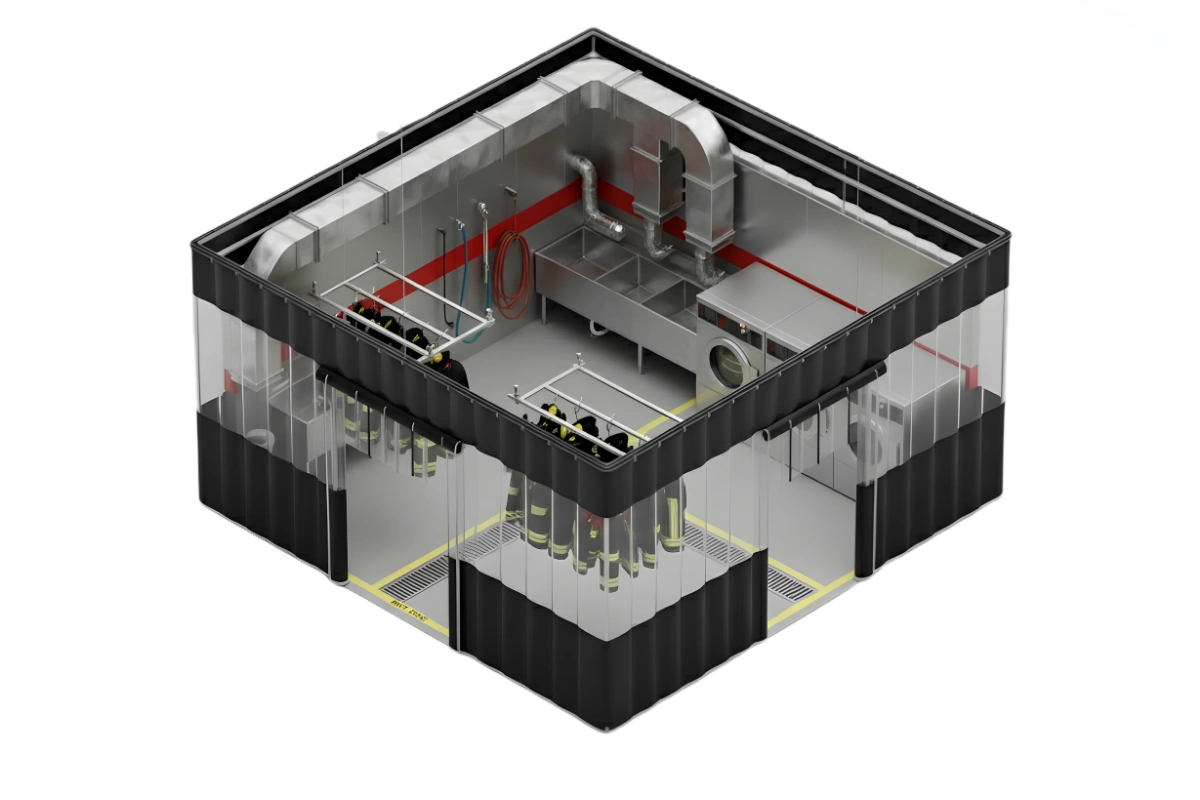

How Flexible Curtain Systems Improve Decon Workflow

Flexible curtain systems help stations create a controlled hot zone where crews can move through each cleaning step quickly and safely. They keep contaminated gear contained, support a smooth path from gear drop to washdown and rinse, and can be adjusted within minutes during busy shifts. These systems also guide foot traffic, reduce accidental cross-contact, and let multiple teams work at the same time without slowing each other down.

• Help direct foot traffic through each cleaning step. They guide firefighters along a clear route. This prevents confusion during cleanup times. It also keeps the workflow predictable.

• Reduce the chance of accidental cross-contact. A set path lowers the risk of mistakes. Crews know where to go at each stage. This keeps movement safer and more controlled.

• Allow teams to manage cleanup without slowing each other down. The zone stays organized for everyone. Crews can work at the same time. This helps the entire process stay efficient.

Containment Control

Keeps overspray, soot, and contaminated runoff sealed inside the hot zone.

Fast Setup and Flexibility

Systems glide smoothly to open, close, or expand zones to match the station’s needs.

Easy Clean-Down

Wipe-clean surfaces allow quick sanitation between gear-cleaning cycles.

Key Features That Strengthen Your Decon Workflow

Choosing the right setup helps your decontamination area work more smoothly and hold up to daily use. Flexible curtain systems come with several features designed to manage moisture, support visibility, and create a more controlled space during turnout gear cleaning. Knowing what to look for makes it easier to select a setup that fits your station’s needs.

| Feature | What to Look For | Why It Matters for Hot Zone Isolation and Turnout Gear Cleaning |

|---|---|---|

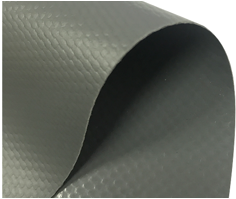

| Heavy-duty vinyl/PVC | 18oz+, reinforced edges | Handles chemicals, water pressure, and frequent decon cycles |

| Custom sizing | Tall heights, wide spans | Isolates full hot zones or gear-cleaning lanes |

| Track systems | Ceiling or wall mounted | Allows fast creation or adjustment of zones |

| Clear windows | Vision panels | Monitor gear cleaning without entering the hot zone |

| Weighted bottoms | Seals and weights | Keeps contaminants from escaping under the curtain |

By focusing on the right features, your station can build a decontamination setup that stays durable, easy to manage, and dependable during busy shifts. With these details in place, choosing the right solution becomes much clearer, especially when comparing the options available for different station layouts.

Material Options

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Recommended Solutions for Fire-Station Use

With the key features in mind, here are three enclosure options that work well for fire-department decontamination zones. Each one supports cleaner workflows, stronger containment, and smoother turnout-gear handling inside the bay.

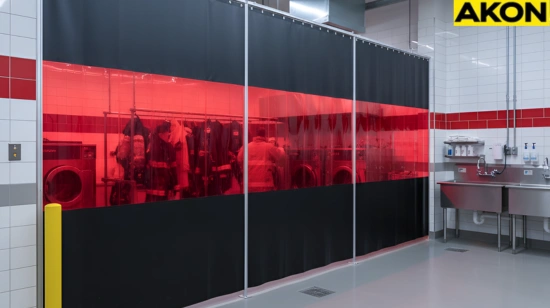

Clear Vinyl Enclosures

Clear Vinyl Enclosures are ideal for stations that want full visibility while keeping the hot zone securely contained. They help officers supervise gear cleaning without stepping inside the controlled area.

• Maintains visibility throughout the washdown space

• Lets supervisors monitor gear cleaning safely

• Creates bright, open zones without breaking containment

• Pairs well with areas that need clear lines of sight

Opaque Vinyl Enclosures

Opaque Vinyl Enclosures are a great fit for stations that need privacy or visual separation during turnout-gear cleaning. Their solid panels help control distractions and reduce exposure to sensitive cleanup steps.

• Provides visual privacy during gear cleaning

• Helps reduce glare and outside distractions

• Creates a clean visual boundary for controlled zones

• Works well for stations that prefer a more defined separation

Insulated Vinyl Enclosures

Insulated Vinyl Enclosures work well in bays where temperature changes or strong airflow affect cleanup. Their thick, insulated construction supports stability during rinse cycles and high-moisture periods.

• Helps maintain a steady environment during washdowns

• Adds extra control in cold or draft-heavy bays

• Built to hold up to moisture, steam, and daily cleaning

• A reliable choice for stations wanting a more controlled hot zone

Frequently Asked Questions

FAQs: Fire Department Decontamination Zones

How do these systems isolate the hot zone in our fire station?

They create a physical barrier that separates contaminated gear from the rest of the bay. Clear, opaque, and insulated vinyl enclosures all help keep residue and moisture contained where it should stay.

Can these enclosures contain runoff and residue during turnout gear cleaning?

Yes. Their wipe-clean vinyl surfaces and weighted bottoms help keep overspray, runoff, and loose debris inside the controlled washdown area.

How do we choose the right size for our decontamination zone?

Start by measuring your bay height, the cleaning path, and any equipment clearances. Most stations choose custom sizing so the enclosure fits the exact hot zone layout.

Are these enclosure materials fire-retardant and chemical-resistant?

Many stations select insulated or heavy-duty vinyl options because they offer fire-rated and chemically durable features ideal for daily decontamination work.

How do sliding systems compare to building a permanent wall?

Sliding enclosures install faster, cost less, and can adjust as your workflow changes. Permanent walls take longer to build and cannot adapt to new layouts.

What kind of maintenance do vinyl enclosures require?

Most only need a quick wipe-down with mild soap and water. An occasional check on the track or hardware helps keep everything moving smoothly.

Can these systems be customized to fit our truck bay layout?

Yes. Clear, opaque, and insulated vinyl enclosures can be built in custom heights, widths, and track paths to match your apparatus spacing and cleaning zones.

How long does installation usually take?

Most systems can be installed within a few hours to a single day. Larger insulated layouts or long track runs may take slightly longer.

Can we add visibility panels for supervision?

Clear Vinyl Enclosures already provide full visibility. Opaque and insulated options can include vision panels so officers can monitor cleaning without entering the hot zone.

Will these enclosures work with our current lighting and airflow?

Yes. Clear vinyl brightens the space, while opaque and insulated versions help manage airflow and drafts in busy bays.

Are these systems strong enough for high-pressure washdowns?

Yes. Vinyl materials handle water, soap, and constant moisture, making them suitable for stations that wash turnout gear every day.

Can we reconfigure the setup later if our workflow changes?

Sliding track systems allow you to expand, relocate, or reshape the enclosure as your decon routine evolves.

Will the enclosure block truck movement in the bay?

No. The track system can be placed outside vehicle paths, and the enclosure can slide fully open when trucks need to move.

Are these enclosures built for daily decon cycles?

Yes. Insulated and standard vinyl options include reinforced seams and durable construction built for heavy use.

What vinyl options can we choose from?

You can select Clear Vinyl Enclosures for visibility, Opaque Vinyl Enclosures for privacy, or Insulated Vinyl Enclosures for better temperature and airflow control.

Can we separate more than one area inside the station?

Yes. Multiple enclosures can work together to create gear drop zones, rinse lanes, and clean staging areas.

How do we clean the vinyl after each use?

A quick wipe with mild soap and warm water keeps the panels clean. Most stations wipe down surfaces after washdowns to prepare for the next cycle.

Do these enclosures work well during winter months?

Insulated Vinyl Enclosures help maintain a more stable environment during cold-weather operations when washdowns create steam or drafts.

Can we add sealing options for better containment?

Yes. Weighted bottoms, floor sweeps, and tighter edge seals help control airflow and improve containment in uneven or draft-heavy bays.

Do we need a professional installer?

Simple layouts can be installed by station staff. Larger insulated systems or long track runs may benefit from professional installation to ensure a smooth setup.

Improving Your Decon Setup Moving Forward

Creating a clear decontamination zone helps your station control contamination, support safer turnout-gear cleaning routines, and keep daily operations more organized. If your current setup feels limited or outdated, this is a good time to review your workflow and see where Clear Vinyl Enclosures, Opaque Vinyl Enclosures, or Insulated Vinyl Enclosures can help strengthen hot-zone containment. If you want a setup matched to your bay layout, you can request custom sizing or ask for a layout-based quote to find the best fit for your department’s needs.