Airport Maintenance Curtain Walls

Airports need adaptable hangar and staging solutions that minimize downtime and expense. Industrial Curtain Walls for Airport Maintenance Hangars and Staging Areas provide a modular, retractable alternative to fixed walls. In this guide, you’ll learn their key benefits, how they compare to permanent walls, featured aviation-ready solutions, and answers to common questions.

Why Curtain Walls Are Ideal for Hangars and Staging Areas

Airport operations change constantly, from handling different aircraft sizes to setting up staging zones for ground support equipment. Permanent structures often slow down this process, while industrial curtain walls are designed to keep projects moving. They deliver advantages that matter most to contractors, MRO providers, and GSE planners.

Operational Advantages

Industrial curtain walls install in just hours at about one third the cost of permanent structures, helping teams stay on schedule and within budget.

They also bring flexibility that fixed walls cannot match, making it simple to divide hangar bays, set up temporary staging areas, or create inspection zones.

Whenever layouts need to change, curtain walls adapt with ease.

Performance and Safety Advantages

Curtain walls improve safety by acting as barriers that stop sparks, fumes, and overspray from spreading into active hangar zones.

This helps facilities meet NFPA-701 fire safety standards and maintain cleaner, safer work environments.

Insulated options also create controlled zones that protect aircraft components and reduce energy waste across large hangars.

Material Options

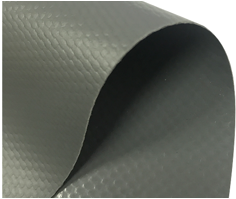

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Core Benefits of Industrial Curtain Walls

Industrial curtain walls do more than divide space, they’re a practical solution to everyday challenges in aviation facilities. From keeping projects on track to improving safety and comfort, they deliver advantages that permanent walls can’t match. Before diving into the specific benefits, here are three common challenges they address:

• Limited flexibility in adapting hangar layouts for shifting aircraft and staging needs. Curtain walls make it easy to reconfigure zones without costly construction.

• Rising costs and long delays tied to traditional wall systems. Curtain walls are budget-friendly and reduce installation time significantly.

• Safety concerns in environments with dust, fumes, sparks, or overspray. Curtain walls create controlled zones that support aviation safety standards

Cost Savings

At about one third the cost of permanent walls, curtain walls protect project budgets.

Safety & Compliance

Made from fire-rated vinyl, curtain walls meet aviation-grade safety standards.

Environmental Control

Insulated options regulate temperature inside large hangars to improve comfort and energy efficiency.

Speed of Installation

Industrial curtain walls can be set up in just hours, avoiding long project delays.

Flexibility

Curtain walls can be moved or reconfigured as operations change.

Curtain Walls vs. Permanent Walls

Once the benefits are clear, the next step is deciding how curtain walls measure up against permanent construction. For airport contractors, MRO providers, and GSE planners, the differences can directly affect costs, project timelines, and long-term flexibility.

| Feature | Curtain Walls (Benefits for Studios) | Permanent Walls (Limitations) |

|---|---|---|

| Installation Time | Installed in hours or days → no downtime | Weeks or months → schedule disruption |

| Cost | Affordable, modular investment | High, fixed renovation cost |

| Flexibility | Perfect for multi-room modular studios | Fixed, no adaptability |

| Privacy & Acoustics | Adjustable with material choice | Static and unchangeable barrier |

| Custom Look | Colors, fabrics, and branding options | Limited once built |

Curtain walls provide aviation facilities with speed, adaptability, and cost efficiency, while permanent walls often lock projects into rigid layouts and higher upfront expenses. For environments where operations evolve quickly, the flexibility of curtain walls makes them the smarter, future-ready choice.

Featured Curtain Wall Solutions for Aviation

After comparing curtain walls with permanent construction, the next step is choosing the right system for your facility. Below are three featured solutions tailored to meet the needs of airport contractors, MRO providers, and GSE planners.

Custom Aircraft Hangar Divider Kit

This system is built for large hangar spaces that need quick, adaptable zoning. It lets teams partition bays efficiently while maintaining clear visibility where it matters most.

• Heavy-duty vinyl built for aviation environments

• Optional vision panels to improve visibility and supervision

• Modular design for dividing bays or staging areas

Insulated Aerospace Curtain System

When controlling temperature and humidity is essential, this solution offers insulation that supports both comfort and energy efficiency. It’s ideal for protecting sensitive aircraft parts or staging ground support equipment without building costly permanent walls.

• Added insulation for temperature and humidity control

• Reduces energy loss in large hangars

• Ideal for staging GSE or protecting sensitive aircraft parts

Quick-Ship NFPA-701 Clear Curtain

For urgent projects, this system balances speed with compliance. It provides fire-rated safety while keeping hangar operations visible and on schedule.

• Transparent PVC material for visibility across zones

• NFPA-701 fire-rated for compliance and safety

• Quick-ship availability for urgent aviation projects

Frequently Asked Questions

FAQs: Airport Maintenance Hangars and Staging Areas

How fast can Industrial Curtain Walls for Airport Maintenance Hangars and Staging Areas be installed?

They can be set up in just a few hours, keeping downtime minimal so hangar operations continue smoothly.

Are curtain walls durable enough for long-term use in busy hangars?

Yes. Reinforced vinyl and galvanized tracks are engineered to handle years of heavy-duty aviation traffic.

Can I customize curtain walls for GSE staging zones?

Absolutely. You can choose custom sizes, add motorized doors, or include vision panels to streamline equipment flow.

Do these curtain walls meet fire and aviation safety standards?

Yes. Most models, including our Quick-Ship NFPA-701 Clear Curtain, are fire-rated and fully compliant with aviation safety requirements.

How do Industrial Curtain Walls for Airport Maintenance Hangars and Staging Areas compare to permanent walls?

Curtain walls are modular, relocatable, and reconfigurable, unlike permanent walls which are fixed and costly to change.

What kind of maintenance do aviation curtain walls require?

They need minimal upkeep. Wipe down vinyl with mild cleaners and check seals or tracks periodically.

Can curtain walls help reduce noise in large hangars?

Yes. Vinyl materials dampen sound, creating quieter zones for staging or inspections.

Which curtain wall is best for temperature and humidity control?

Our Insulated Aerospace Curtain System is designed to regulate climate, protecting sensitive aircraft components and GSE.

Are curtain walls movable after installation?

Yes. They can be relocated or reconfigured, similar to modular partitions used in multi-room studios.

Can logos or colors be added to curtain walls?

Yes. We offer customization with branded colors, printed logos, and identification panels.

Will curtain walls interfere with aircraft movement inside hangars?

No. They retract or slide open on tracks, leaving plenty of clearance for aircraft or equipment.

Are they resistant to aviation chemicals and fuel fumes?

Yes. Materials are designed to withstand exposure to common aviation chemicals and cleaners.

How tall can Industrial Curtain Walls for Airport Maintenance Hangars and Staging Areas be made?

They can reach up to 40 feet, accommodating even wide-body aircraft facilities.

Can curtain walls be used temporarily during hangar renovations?

Yes. They are ideal for creating temporary partitions without permanent construction.

Do I need special tools or outside contractors to install them?

No. Most systems are designed for straightforward installation with standard hardware, often by in-house teams.

Can curtain walls safely separate welding, painting, or other hazardous work?

Yes. Specialized materials block sparks, fumes, and overspray, making them safe for high-risk maintenance tasks.

Are there options for outdoor or semi-exposed staging areas?

Yes. Weather-rated models with seals and reinforced vinyl can be installed in semi-outdoor areas.

Do curtain walls affect visibility inside hangars?

No. Clear PVC panels or see-through sections provide supervision while still separating work zones.

Which curtain wall is best for urgent aviation projects?

Our Quick-Ship NFPA-701 Clear Curtain is designed for rapid deployment with fire-rated compliance.

How can I order or request a custom quote?

Contact our team to discuss specifications for Industrial Curtain Walls for Airport Maintenance Hangars and Staging Areas, including the Custom Hangar Divider Kit and other aviation-ready solutions.

Aviation-Ready Curtain Walls, Built for You

Industrial curtain walls give airport contractors, MRO providers, and GSE planners a smarter way to adapt hangars and staging areas as operations evolve. Instead of long construction projects, they offer flexibility and speed that match the pace of aviation. Ready to reconfigure your hangar with confidence? Contact us today for a custom aviation-ready curtain wall solution.