Woodturning & Lathe Chip Curtains

Woodturning throws shavings, curls, chips, and dust into the surrounding area, affecting safety and workspace cleanliness for hobbyists and professionals. Modular curtain wall systems help contain debris and keep turning areas organized. This article covers common debris problems, how these systems work, key features, recommended setups, frequently asked questions, and how to choose the right solution.

The Problem: Chip, Dust and Shavings in Woodturning Workspaces

Woodturning produces more debris movement than most people expect. Once the lathe begins spinning, wood chips, curls, and fine dust can travel far beyond the turning zone and create new challenges for both hobbyists and professionals.

How Debris Spreads in Woodturning Areas

When the tool meets the spinning blank, chips and long shavings can travel several feet in unexpected directions. They land on benches, shelves, nearby machines, and walkways that should remain clear. At the same time, fine dust drifts into finishing areas and storage drawers, settling into delicate tools and slowing down the workflow.

This buildup makes it harder to maintain a clean, manageable workspace. Over time, the amount of debris can spread enough to disrupt both ongoing projects and routine shop tasks.

Why Debris Creates Safety Issues and Makeshift Barriers Fail

Uncontrolled debris can create several hazards. Shavings on the floor increase the risk of slipping, scattered chips can distract an operator during a cut, and unpredictable chip spray can affect anyone walking through the space.

Many woodworkers try tarps or plastic sheets, but these materials shift easily, tear under impact, and rarely provide a secure seal. Over time, they add to the cleanup rather than prevent it. This makes it difficult to maintain a safe turning environment, especially in shops with limited space.

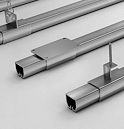

What Are Modular Curtain Wall Systems

After knowing how easily debris spreads in a turning space, it helps to have a system that keeps it contained. Vinyl panel setups mounted on smooth-gliding tracks create a defined work zone that’s easy to manage in both small garages and multi-lathe studios. With adjustable layouts, woodworkers can maintain a cleaner and more focused turning area.

• Easy to install. Most systems mount to existing ceilings or overhead supports without the need for major modification. This makes them accessible for hobbyists working in garages and professionals managing larger studios.

• Simple to clean. Vinyl panels can be wiped down with basic shop cleaners to remove dust and residue. There are no complicated cleaning steps or special materials required.

• Customizable to any workspace. Panels come in various sizes and layouts that fit both small turning corners and wide shops with multiple lathes. This level of adaptability helps woodworkers maintain an efficient and well-organized workspace.

Weather Protection

Reinforced vinyl panels absorb repeated chip impact and stay reliable through daily turning work.

Adaptable Layout Control

Track-mounted panels slide smoothly so users can reconfigure or adjust their turning space whenever needed.

Clear Viewing Panels

Optional windows make it easy to monitor turning activity without stepping into the debris zone.

How Curtain Wall Systems Improve Shaving, Chip and Dust Containment

With the system structure in mind, it becomes easier to understand how these panels change the way debris behaves in a turning space. By creating a controlled zone around the lathe, modular curtain wall systems help woodworkers keep their shop cleaner and safer while staying focused on their projects.

| Benefit | Description |

|---|---|

| Capture debris at the source | A defined enclosure helps contain flying shavings, chips, and curls before they spread, keeping the turning area more organized from start to finish. |

| Reduce dust drift | Fine dust stays within the turning zone instead of reaching finishing rooms, shelves, or delicate tools, improving overall cleanliness. |

| Promote safer movement | Clearer walkways and shared spaces reduce the risk of slipping or being affected by scattered chips. |

| Cut down on cleanup time | With debris collected in one area, woodworkers spend less time sweeping and more time focusing on their turning projects. |

| Adapt to changing shop layouts | Modular configurations can shift or expand as projects change, making it easy to adjust the enclosure when needed. |

| Method | Advantages | Limitations |

|---|---|---|

| Permanent drywall or brick wall | Strong containment and a professional look. | Expensive, inflexible, and slow to install. |

| Makeshift plastic sheeting | Low cost and quick to hang. | Tears easily, weak sealing, and an unprofessional appearance. |

| Modular curtain systems | Durable, adjustable, and focused on debris control. | Requires proper measurement and mounting. |

These improvements make modular curtain wall systems a practical choice for woodturners who want cleaner workspaces and better control over their tools and environment. With debris contained and movement simplified, both hobbyists and professionals can focus more on the craft itself. Next, we will explore the best system configurations to help you choose the right setup for your shop.

Material Options

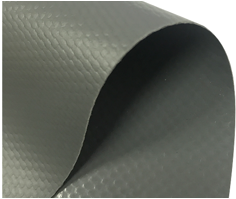

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Best Solutions for Woodturning Chip and Shaving Control

With containment benefits in mind, the next step is choosing the right enclosure for your shop. Below are three enclosure options that work especially well for both hobbyists and professionals who want cleaner, safer, and more controlled woodturning spaces.

Clear Vinyl Enclosures

Clear vinyl enclosures are ideal for woodturners who want visibility without losing containment. They are perfect for teaching, monitoring, or any workspace where a clear view of the lathe improves safety and communication.

• Maintain full sightlines for teaching, demos, or monitoring turning work.

• Help contain chips and shavings without blocking natural or overhead light.

• Easy to wipe clean after long turning sessions.

• Ideal for studios where visibility supports safety and learning.

Opaque Vinyl Enclosures

Opaque vinyl enclosures are great for creating a focused turning zone with fewer visual distractions. They suit turners who want reliable chip containment along with a cleaner, more private work area.

• Helps reduce visual distractions around the lathe.

• Thick, durable vinyl handles high-output lathes and daily workloads.

• Creates a more contained space for focused turning.

• Works well for both hobby shops and professional studios.

Insulated Vinyl Enclosures

Insulated vinyl enclosures offer comfort and environmental stability around your lathe. They are especially helpful for long turning sessions, multi-station shops, or projects sensitive to temperature changes.

• Help stabilize shop temperature around the turning area.

• Offer sound-softening benefits that limit distractions in busier spaces.

• Useful for finishing tasks that react to temperature shifts.

• Great for multi-station production areas or extended turning sessions.

Frequently Asked Questions

FAQs: Common Questions From Hobbyists and Professional Woodturners

Can clear or opaque vinyl enclosures stop long shavings and high-speed chips from leaving the lathe area?

Yes. These enclosures create a defined barrier that helps keep shavings, chips, and curls contained inside the turning zone.

Are vinyl enclosures suitable for small garage workshops?

Yes. Clear or opaque vinyl setups can be sized to fit tight corners, low ceilings, and compact turning spaces.

Can these enclosures handle dust and debris from large professional lathes?

Yes. The reinforced vinyl material performs well with high-output machines in busy turning studios.

Are vinyl enclosures safe around occasional heat or sparks from turning tools?

Yes. They are designed for normal turning conditions and can handle light tool friction safely.

How long do clear or opaque vinyl panels last with heavy chip impact?

Most panels last for years with regular cleaning and proper care in active woodturning environments.

Are vinyl enclosures more affordable than building a separate turning room?

Yes. They cost significantly less than constructing walls and require no major renovation.

Can these enclosures expand or move if my shop layout changes?

Yes. The panels can be reconfigured, relocated, or expanded as your shop evolves.

Can I use one enclosure around more than one lathe?

Yes. Many woodturners enclose multiple lathes inside one containment area.

Do clear vinyl panels allow enough light for detailed turning work?

Yes. Clear vinyl lets natural and overhead light pass through easily, keeping the workspace bright.

Are insulated vinyl enclosures helpful for temperature-sensitive projects?

Yes. They help maintain a more stable environment around the lathe during finishing or long sessions.

Are the panels easy to clean after turning sessions?

Yes. A quick wipe with common shop cleaners removes dust and residue.

Will insulated enclosures help reduce shop noise?

Yes. Insulated vinyl softens sound, which is helpful in shared or busy workspaces.

Can vinyl enclosures help protect nearby finishing or sanding areas from chips?

Yes. They keep debris contained so clean zones stay cleaner for longer.

Do I need special tools to install these enclosures?

No. Most setups mount to standard ceiling supports using simple hardware.

Are clear vinyl enclosures good for teaching or mentoring sessions?

Yes. The clear panels allow easy supervision and communication during hands-on turning instruction.

Will these enclosures still work if my floor is uneven?

Yes. The flexible panel design helps accommodate mild variations in flooring.

Can I order custom heights or widths for my turning space?

Yes. Custom sizes are available to match nearly any shop layout.

Do the panels help keep chips off nearby shelves and tools?

Yes. Containment reduces debris reaching tools, cabinets, and storage areas.

Are the panels heavy or difficult to slide?

No. The track-mounted design makes them smooth and easy to move.

Will these enclosures help my shop look more organized?

Yes. A defined turning zone creates a cleaner, more professional workspace.

Improve Your Turning Space With the Right Setup

A well-contained turning space helps both hobbyists and professionals work cleaner, safer, and with better focus. Vinyl panel systems offer an easy way to control debris, protect surrounding tools, and create a more organized workspace without the cost or commitment of permanent walls. If you’re ready to upgrade your turning area, explore the available panel options or request a custom layout tailored to your shop’s needs.