Water Treatment Plant Curtain Walls

Using curtain walls in water treatment plants for moisture and chemical isolation helps facilities address constant challenges with water, chlorine, and compliance. This article explains why curtain walls are the smarter choice, outlines their key materials and features, highlights practical applications, recommends products, and answers common questions for safer and more efficient operations.

Why Curtain Walls Are Ideal for Water Treatment Facilities

Running a water treatment facility requires balancing cost, safety, and efficiency. Managers must find ways to protect equipment, maintain compliance, and keep workflows moving without the delays and high costs of traditional construction. Curtain walls step in as a flexible, affordable, and reliable solution.

The Challenges of Permanent Walls in Treatment Facilities

Permanent walls often create more issues than they solve. They lock plants into rigid layouts that are difficult and expensive to change, while construction projects cause extended downtime that disrupts operations.

These barriers add to overall costs and limit flexibility, making it harder for managers to adjust as compliance rules or operational needs evolve. In a fast-changing industry, this lack of adaptability can become a serious obstacle to efficiency.

The Advantages Curtain Walls Bring to Plant Operations

Curtain walls provide targeted solutions without the drawbacks of fixed construction. They help maintain moisture control in sensitive areas, create secure zones for chemical isolation, and support wastewater partitioning to improve sanitation.

At roughly one-third the cost of permanent walls and with easy reconfiguration, they allow facilities to stay efficient, compliant, and adaptable. This combination of affordability and versatility makes curtain walls a long-term investment in operational resilience.

Material Options

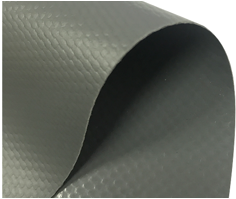

18 oz Reinforced Vinyl (standard)

20 mil Clear PVC For Clarity

Available in Multiple Colors

Strong Materials

Materials & Design Features

Curtain walls are built to handle the demanding conditions inside water treatment plants. Their materials, hardware, and accessories are designed to deliver long-lasting performance where moisture and chemical exposure are constant.

• Material Options: Opaque vinyl (13 oz or 18 oz) and clear PVC (20 mil or 30 mil) are both fire-retardant and tested to NFPA-701 and CFM standards. Tinted vinyl options (14 mil or 40 mil) add UV protection and resist wear in corrosive zones.

• Hardware and Customization: Each system uses 16-gauge galvanized steel tracks with roller hooks for smooth and reliable operation. Facilities with unique layouts can choose free-standing frames up to 20 feet tall or simple grommet-only setups.

• Accessories for Better Isolation: Accessories enhance performance by sealing gaps and improving safety. Vision panels, valances, floor sweeps, Velcro edges, magnets, chain weights, and anchor straps keep the system secure in active environments.

Durability

Heavy-duty vinyl and PVC resist chlorine, wastewater, and repeated wash-downs. They maintain strength even under constant exposure.

Flexible

Ceiling tracks, free-standing frames, or grommet-only setups adapt to any facility layout. This flexibility allows managers to change or expand zones whenever needed.

Visibility

Clear vision panels let staff monitor wastewater and chlorine zones while keeping them contained. This balance supports compliance and safety without slowing workflows.

Applications in Water Treatment Facilities

Once the materials and design features are in place, the real value of curtain walls comes from how they are used inside water treatment facilities. They allow managers to create safer, more organized spaces that support compliance and efficiency without requiring permanent construction.

| Application | Benefit |

|---|---|

| Wastewater Partitioning | Curtains divide wet and dry areas to reduce cross-contamination. This separation makes cleaning routines faster and helps maintain sanitation standards. |

| Chlorine Zone Containment | Curtain walls form a secure enclosure around chlorine handling and storage areas. This setup protects staff, shields equipment, and helps facilities meet safety regulations. |

| Wash-Down Protection | By keeping overspray confined to designated spaces, curtain walls simplify cleanup. They also prevent water from reaching other zones and disrupting work. |

| Moisture & Overspray Control | Curtains provide a barrier that shields control rooms and sensitive equipment from water damage. This protection extends the life of critical systems and reduces maintenance costs. |

Curtain walls prove their usefulness by adapting to different parts of a treatment plant, from wastewater processing zones to chemical storage areas. With their ability to protect critical spaces and streamline operations, they give managers a practical tool for improving both safety and efficiency.

Recommended Curtain Solutions

With so many applications inside a water treatment plant, the next step is choosing the right curtain system for specific needs. These three solutions are designed to handle chlorine, wastewater, and high-moisture environments while improving daily operations.

Heavy-Duty Vinyl Curtain Kit

This curtain kit is built with 18 oz vinyl that resists chlorine and corrosive chemicals. It provides long-term durability in zones where chemical exposure and worker safety are a top priority.

• deal for chlorine storage and dosing areas

• Reduces risks during chemical handling

• Lowers maintenance costs by preventing corrosion damage

Clear Vision Panel Curtain System

Made with transparent PVC and optional tinted panels, this system offers visibility while containing wash-down spray. It ensures teams can monitor operations safely without pausing workflows.

• Perfect for wash-down sections

• Simplifies sanitation routines by keeping spray confined

• Improves oversight of workers and equipment in active zones

Modular Wastewater Partition Package

This package includes seals, sweeps, and anchors to create airtight partitions between wet and dry spaces. It helps facilities cut cleaning time and maintain cleaner, more organized workflows.

• Creates reliable wastewater partitions for better hygiene

• Reduces labor hours by making cleaning more efficient

• Prevents water intrusion into sensitive areas like control rooms

Frequently Asked Questions

FAQs: Using Curtain Walls in Water Treatment Plants for Moisture and Chemical Isolation

What is the best curtain wall system for wastewater partitioning in a treatment plant?

The Modular Wastewater Partition Package is designed for this purpose, using floor sweeps, magnets, and anchors to create sanitary separation between wet and dry areas.

Can I use curtain walls for chlorine zone containment?

Yes, Heavy-Duty Vinyl Curtain Kits with 18 oz vinyl are corrosion-resistant and ideal for chlorine handling and storage areas.

Are curtain walls strong enough for continuous wash-down environments?

Industrial vinyl is built for wash-down zones, resisting overspray and repeated cleaning without losing durability.

Do curtain walls meet OSHA or fire safety standards?

Yes, most models are NFPA-701 fire-retardant and OSHA-compliant, making them safe for regulated water treatment environments.

How do curtain walls improve efficiency compared to permanent partitions?

They install in hours, cost about one-third of fixed walls, and can be reconfigured as workflows change.

Can visibility be maintained when isolating wastewater or chlorine zones?

The Clear Vision Panel Curtain System uses transparent PVC to allow safe monitoring while maintaining separation.

What materials are recommended for curtain walls in water treatment plants?

Opaque vinyl is best for privacy and chemical resistance, while clear or tinted PVC provides visibility and UV protection.

Do curtain walls resist chemical fumes as well as liquid exposure?

Yes, heavy-duty vinyl options resist both chemical splashes and vapors common in chlorine areas.

How tall can curtain walls be built inside a facility?

Free-standing frames can reach up to 20 feet, and ceiling tracks allow flexible installations around equipment.

Can curtain walls be moved if the plant layout changes?

Yes, modular systems are designed for reconfiguration, making them cost-effective for evolving facilities.

Do curtain walls help reduce odor in chlorine or wastewater zones?

By isolating these areas, curtain walls limit the spread of odors across the facility.

How do curtain walls affect ventilation and airflow?

They create zones that reduce HVAC strain and allow targeted airflow management in treatment areas.

Can curtain walls protect against fire risks in water treatment facilities?

Yes, all Curtain-and-Divider industrial walls are manufactured with fire-retardant materials tested for safety.

What if my facility has uneven floors, can curtain walls still work?

Accessories like floor sweeps and anchor straps ensure a secure seal even on uneven surfaces.

How long does it take to install curtain walls?

Most installations are completed in a single day, minimizing downtime compared to traditional construction.

Are curtain walls resistant to UV damage?

Tinted vinyl panels are available for UV protection, making them ideal for zones with high light exposure.

What kind of maintenance do curtain walls require?

Only routine cleaning with mild detergents and periodic checks of hardware such as tracks and seals.

How do curtain walls improve worker safety in chlorine storage areas?

They create a protective barrier that separates chemical handling zones from staff walkways and equipment.

Are curtain walls compatible with automated pumps or conveyors?

Yes, modular layouts can be designed around existing machinery without blocking access.

Can curtain walls extend the life of electrical or sensitive equipment?

Yes, by blocking moisture and overspray, they reduce corrosion and protect critical systems from failure.

Start Planning Your Custom Curtain Wall Solution

Curtain walls offer water treatment plants a smart way to stay safe, compliant, and adaptable without the expense of permanent construction. Their modular design makes it easier to handle evolving safety standards and operational changes while keeping critical zones protected. If you’re ready to improve efficiency and safeguard your facility, request a tailored curtain-wall layout designed for your plant’s specific needs.